Machine Introduction Video

Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

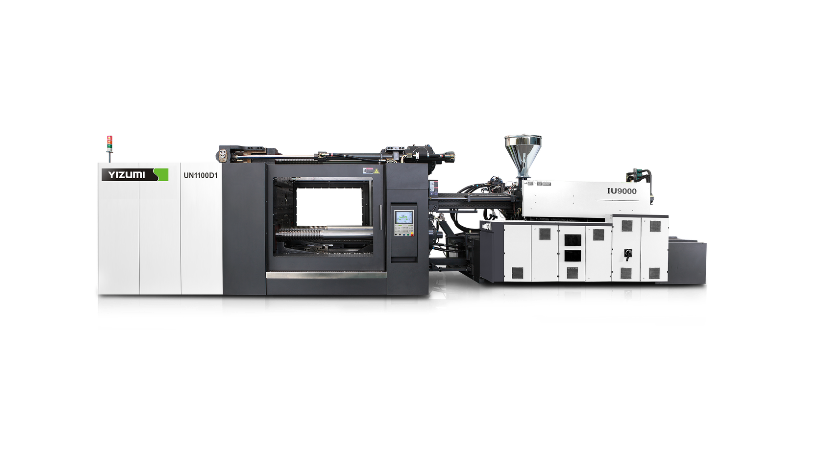

Electric Injection Molding Machine

FF Series Electric Injection Molding Machine

Electric Injection Molding Machine FF Series surpasses traditional machine standards, facilitating seamless automation and intellectualization integration for improved quality consistency and efficiency. Superior in thickness, precision, and complexity, this electric injection molding equipment meets demanding core product needs. Clamping forces range from 900 to 13,800 kN.

Stability and Precision

Automation and Intellectualization

Efficiency and Flexibility

Machine Introduction Video

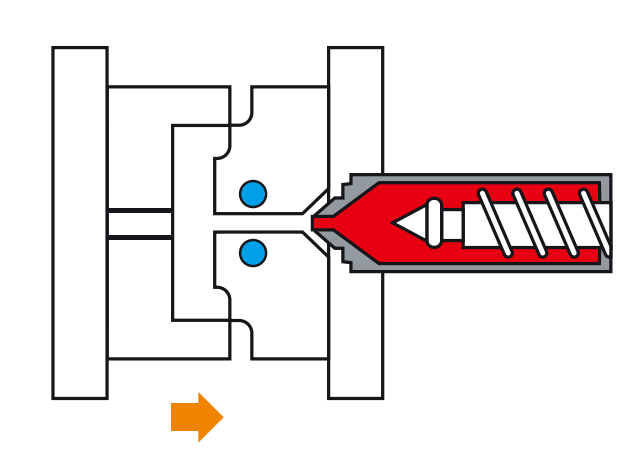

Clamping Unit

Dual-cylinder parallel ejection design

- Uniform force application for mold release.

- Accuracy of ejection position up to 0.2mm, conducive to product accuracy and repeatability.

- Can achieve functions such as various modes of synchronized ejection and ejector retraction, gate cutting inside the mold, etc.

- Accuracy of ejection position up to 0.2mm, conducive to product accuracy and repeatability.

- Can achieve functions such as various modes of synchronized ejection and ejector retraction, gate cutting inside the mold, etc.

High stability of the TBF technology

- The clamping unit adopts the TBF (Tie Bar Free) technology for easy operation and maintenance.

- Keep the mold area clean to prevent product contamination.

- Keep the mold area clean to prevent product contamination.

Unique “SMART” mold protection feature

- Can detect very small obstacles and resistance.

- Reduce the extent of mold damage when there are foreign objects in the mold cavity or faulty operation occurs.

- Reduce the extent of mold damage when there are foreign objects in the mold cavity or faulty operation occurs.

Injection Unit

The use of advanced LGS(Linear Guide Support) technology

Integrated design enhances the overall rigidity of the injection unit. No unnecessary friction. Fast forward and backward.

Built-in hydraulic pump station

Support a variety of molding processes with great flexibility and efficiency. For ejector, nozzle contact force & core pull.

Closed loop injection pressure control technology

- Provide more accurate control for more stable, reliable, and precise molding.

- The stability precision of injection pressure and holding pressure is at ±0.1Mpa.

- The stability precision of injection pressure and holding pressure is at ±0.1Mpa.

Unique servo direct control (SDC) technology

- Four servo motors control injection, plasticizing, clamping, and ejection independently, allowing faster feedback, more responsive control, and improved control accuracy.

- More precise control of speed, position, and pressure to meet the requirements of precision equipment.

- More precise control of speed, position, and pressure to meet the requirements of precision equipment.

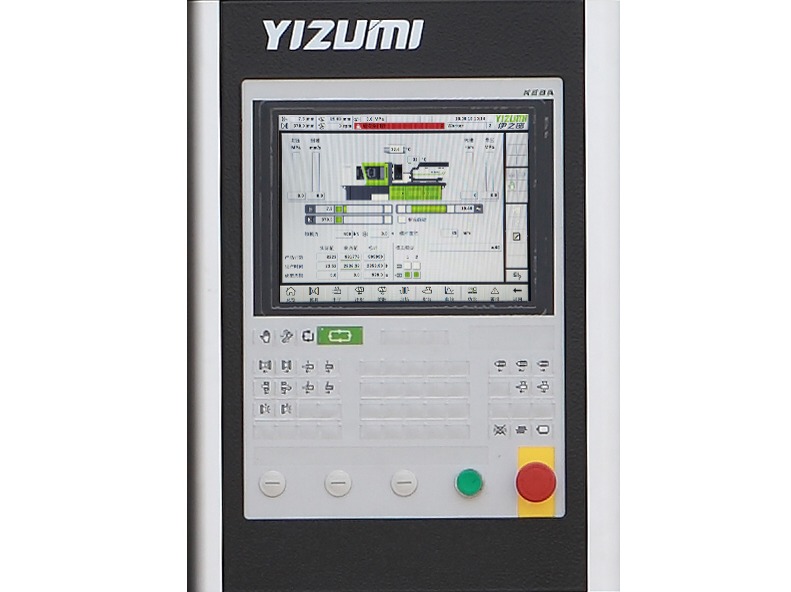

European KEBA2000 Controller

- Standard Process quality control (PDP), and Statistical process control (SPC) features;

- Centralized (networked) real-time remote operation and control;

- The flexible I/O expansion modules allow integration of more features as needed and are programmable

- Centralized (networked) real-time remote operation and control;

- The flexible I/O expansion modules allow integration of more features as needed and are programmable

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.