Machine Introduction

Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

High-speed Injection Molding Machine

PS5 Series High-Speed Injection Molding Machine

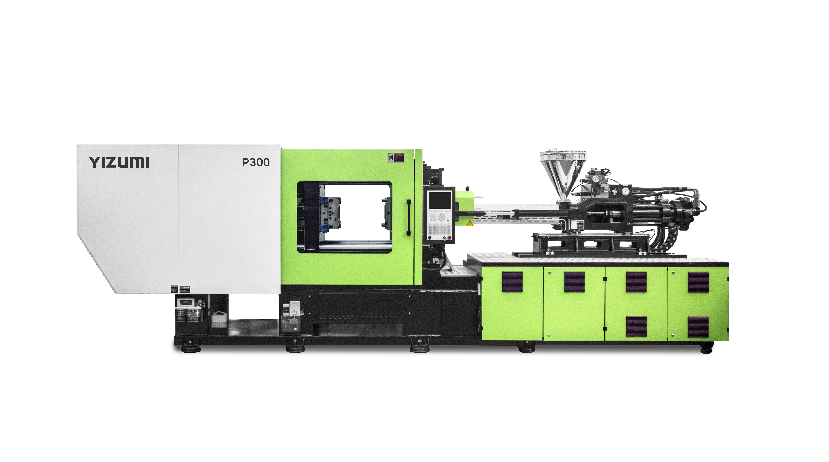

The fifth-generation PS5 Series High-Speed Injection Molding Machines are tailored for industries demanding speed and precision, ideal for food packaging, medical disposables, bottle caps, and daily chemical products. Featuring an optimized control system, enhanced cylinder sealing, and high-rigidity platens, this high-speed injection molding equipment delivers consistent, high-speed performance with max. injection speeds of up to 550?mm/s. Clamping forces range from 2,800 to 5,600?kN.

Efficient

Energy-saving

Reliable

Durable

Machine Introduction

Clamping Unit

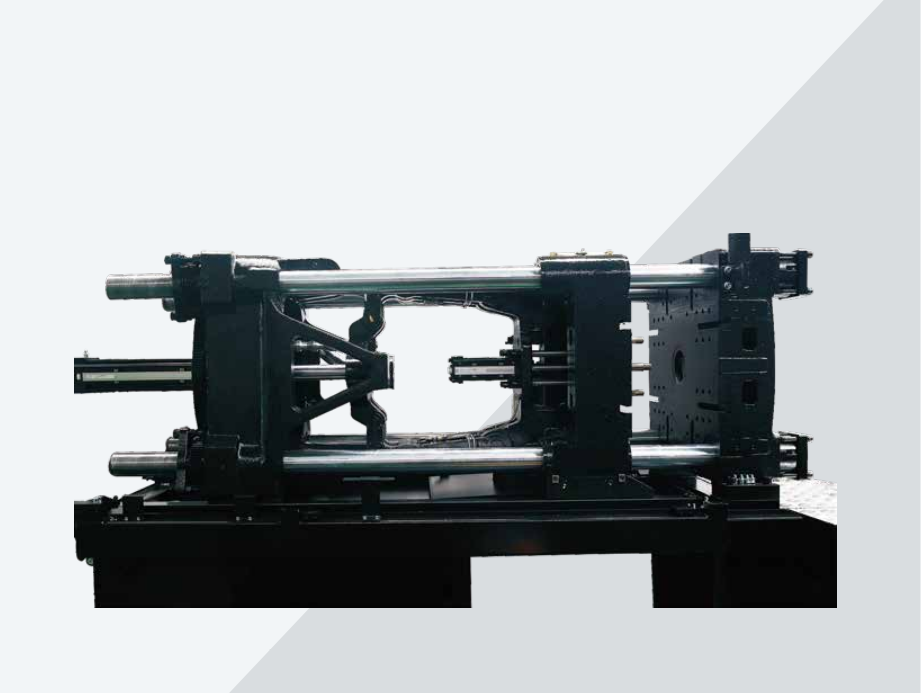

New high-rigidity clamping unit

The reinforced platen, designed for thin-wall precision product molding, has been optimized through finite element analysis to improve the overall mechanical structure, reduce stress, and enhance platen rigidity.

Anti-tilt movable platen design

The entire series features a new anti-tilt platen support design, which improves platen parallelism, prevents tilting during heavy mold operation, and ensures stability and durability under high-speed, long-term operating conditions.

Steel and copper bushings

Both the steel and copper bushings feature a specialized design that reduces lubricant consumption while ensuring optimal lubrication for toggle pins and tie bars during high-speed operation.

Injection Unit

High-speed injection

The introduction of low-pressure, high-speed injection molding and multi-action compound operation design enhances the molding efficiency of thin-wall products. High-speed performance with max. injection speeds of up to 550?mm/s.

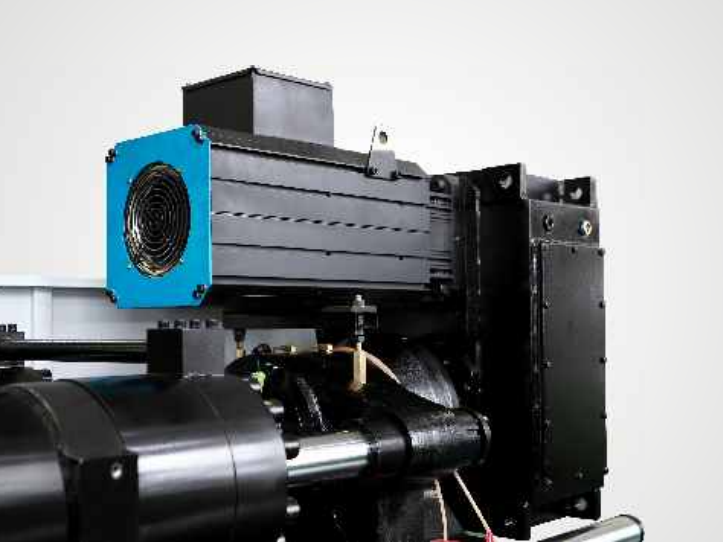

Plasticizing motor

High-speed, high-pressure motors extend the service life of the equipment and enhance the quality and efficiency of plasticizing.

Dual linear guide design for carriage

The injection unit features an integrated cast iron support combined with a dual linear guide design, reducing resistance, minimizing friction during operation, and shortening injection acceleration time.

New hydraulic system

New hydraulic oil circuit system

The optimized hydraulic oil circuit design reduces pressure loss in hydraulic oil for greater energy efficiency.

Mold opening synchronized with plasticizing function

With a multi-pump hydraulic circuit design, PS5 is standard with mold opening synchronized with the plasticizing function. If a mold opening synchronized with ejection is needed, a reliable solution is available as an optional feature.

Control system

Imported hydraulic and electrical components

Major hydraulic and electrical components in all PS5 models are from leading international brands, ensuring superior stability and performance.

Intelligent mold opening

- Mold opening parameter setting is simplified, requiring only two settings: the start and end points.

- Automatic generation and optimization of parameters for mold-opening process, smoother operation.

- Automatic generation and optimization of parameters for mold-opening process, smoother operation.

Intelligent clamping force management system

This system proactively identifies and sets optimal clamping force, monitors and intelligently optimizes clamping force parameters, enabling users to efficiently and conveniently operate the injection molding machine while improving the stability of product quality.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Processes

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.