Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

High-speed Injection Molding Machine

P Series High-speed Injection Molding Machine

High-speed Injection Molding Machine P Series is the top choice for crafting multi-cavity, thin-wall packaging items, meeting the demands of thin-wall containers and enhanced production efficiency. Yizumi provides tailored turnkey solutions of injection molding machines for diverse clients. Clamping forces range from 2,500 to 5,500 kN.

High Speed

The humanized design of the machine

Wide range of application

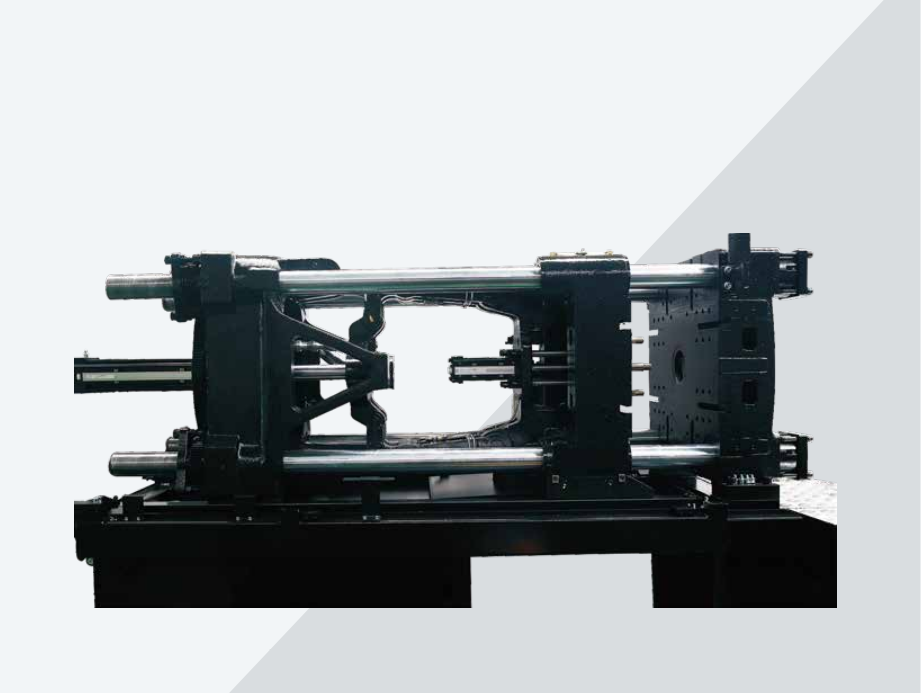

Clamping Unit

Unique Large Beveled Cosshead Toggles Design

A large beveled structure can better transfer force from the tail toggle hole to the center of the platen to minimize the platen deformation, ensure the uniformity of force applied on the platens and mold, extend the service life, and ensure the quality of products.

High-rigid and Low Deformation Platens

- The adoption of reinforced platen design according to the characteristics of thin-walled packaging products.

- With a perfect combination of strength and rigidity, while minimizing the platen deformation, it maintains a flexible and smooth movement.

- With a perfect combination of strength and rigidity, while minimizing the platen deformation, it maintains a flexible and smooth movement.

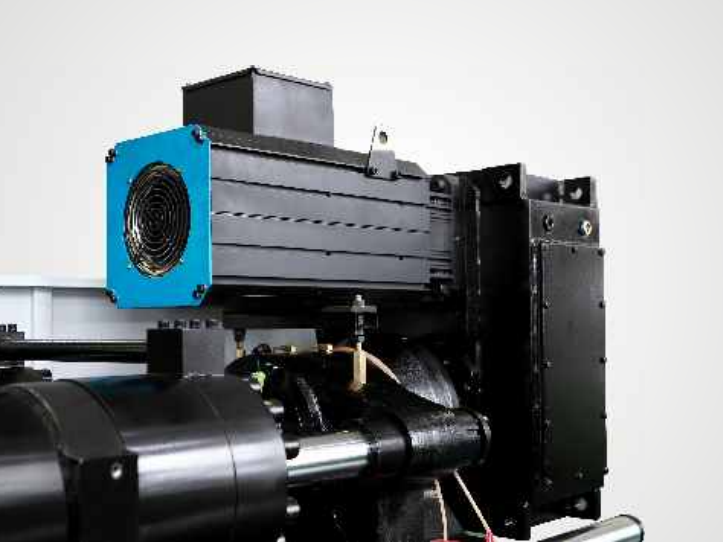

Injection Unit

Horizontal Dual-carriage Design

The adoption of horizontal dual-carriage cylinder design effectively eliminates the turning torque of the injection mechanism and ensures a stable and reliable injection.

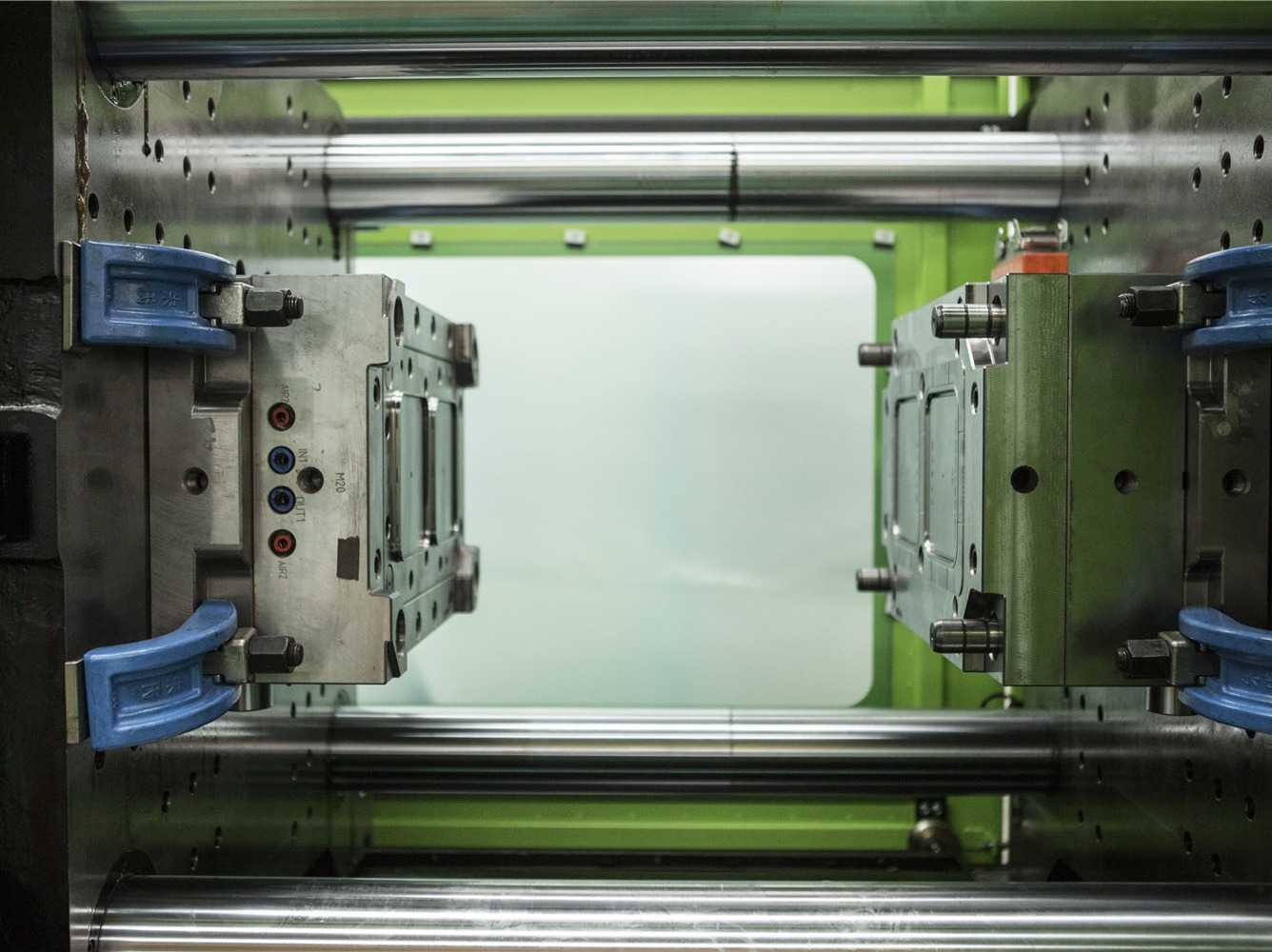

High-speed Mold Opening /Closing Proportional Valve

Further reduce the reaction time. Double the repetitive accuracy of mold opening ends and increase the operating speed of mold opening/closing by 15%-20%, suitable for the production of various precision thin-walled products.

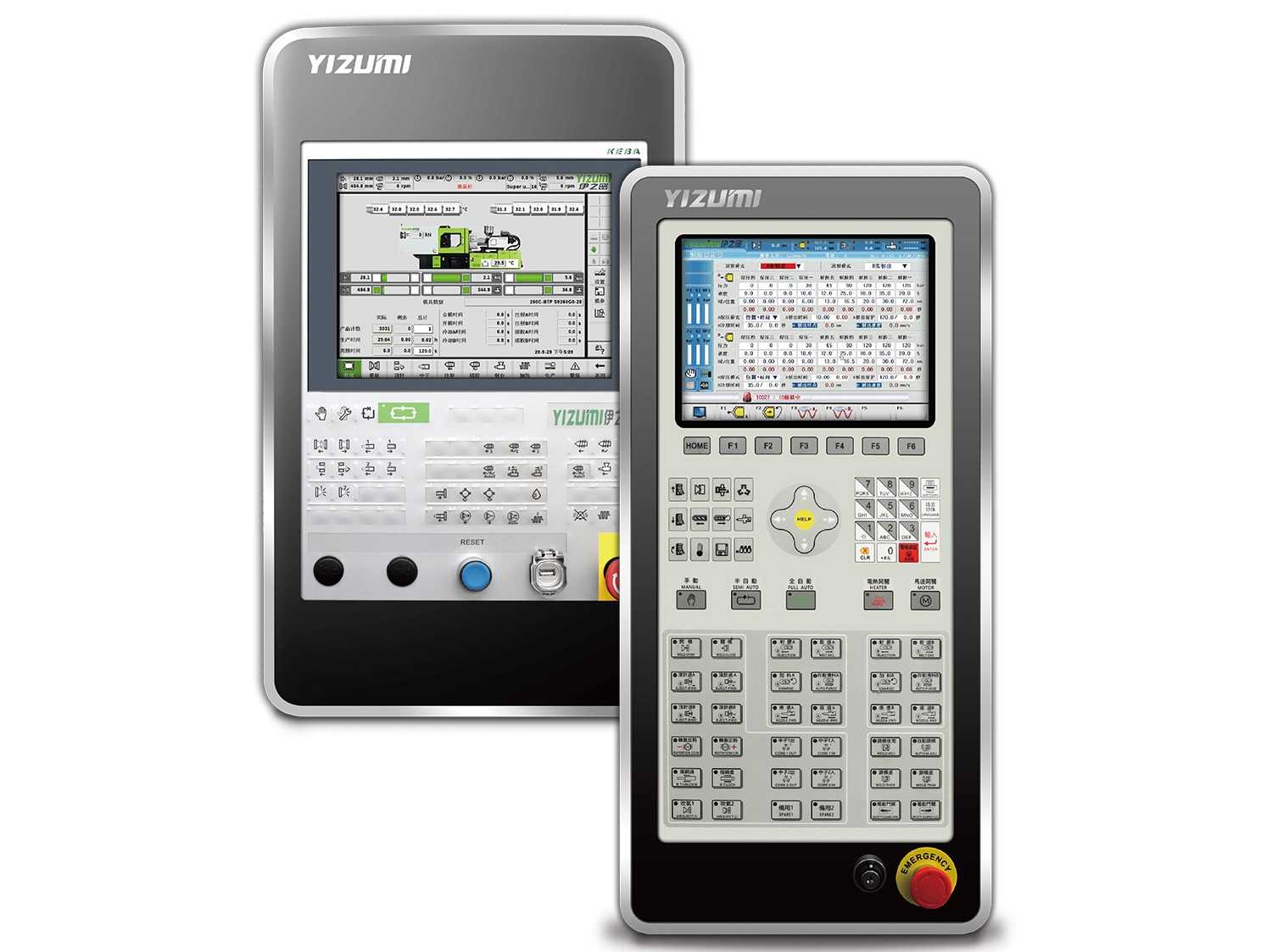

Control System

- Faster processing speed, optimized control rate, and outstanding repetitive accuracy help to achieve more stable product quality.

- Bright, full-color 10-inch touch screen input and easy-to-use operation page.

- Multi-stage injection and plasticizing function pages are easy to use and improve processes accordingly.

- The production management and production monitoring functions can communicate with the peripheral equipment barrier-free.

- Online quality monitoring function and injection molding industry 4.0.

- Bright, full-color 10-inch touch screen input and easy-to-use operation page.

- Multi-stage injection and plasticizing function pages are easy to use and improve processes accordingly.

- The production management and production monitoring functions can communicate with the peripheral equipment barrier-free.

- Online quality monitoring function and injection molding industry 4.0.

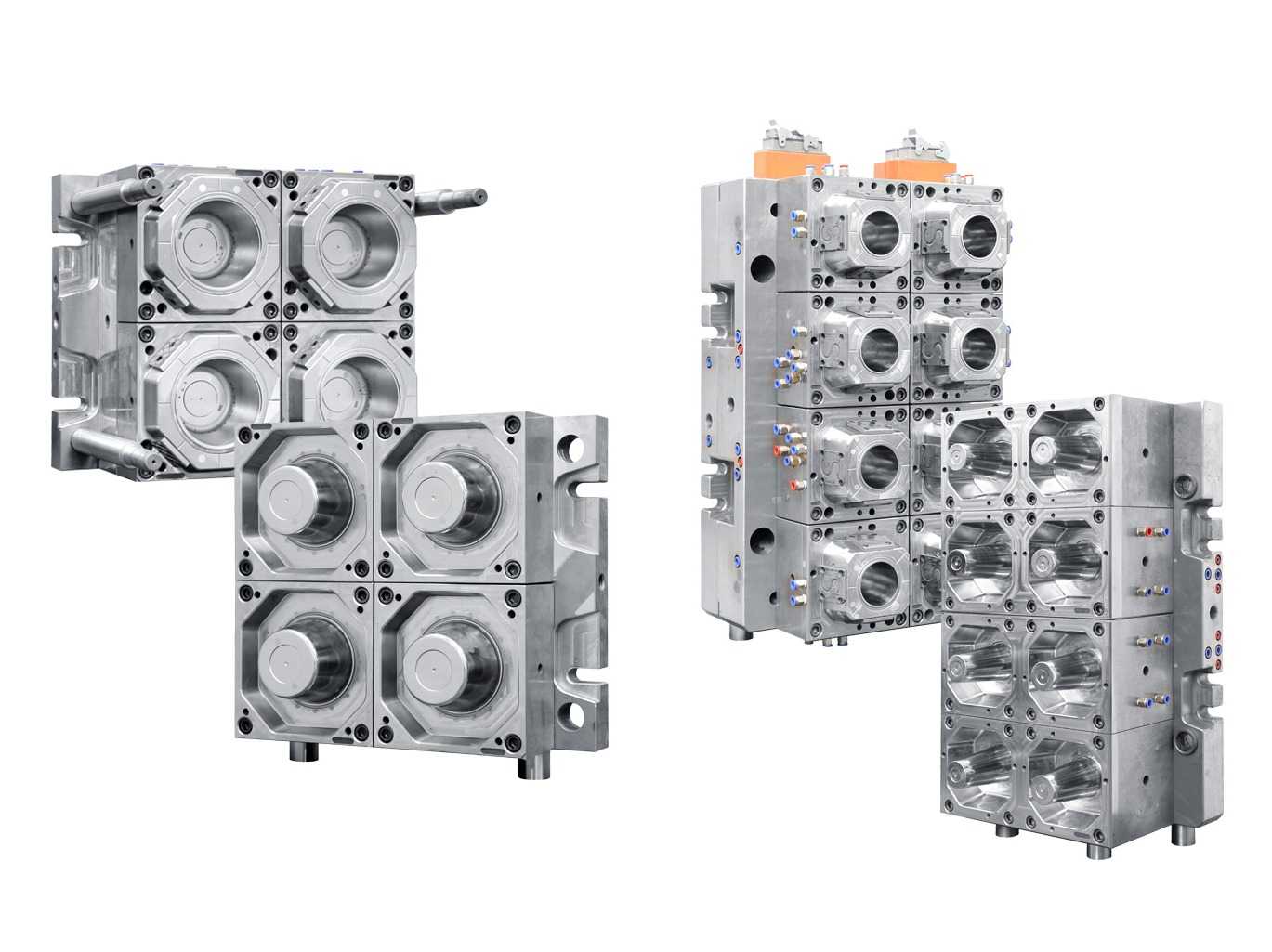

Thin-wall mold

We can offer customized molds for thin-wall injection molding according to customer-specific requirements, to better meet diversified demand.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Processes

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.