Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

Special-usage Injection Molding Machine

UPVC & PPR Series Special Injection Molding Machine For Pipe Fitting

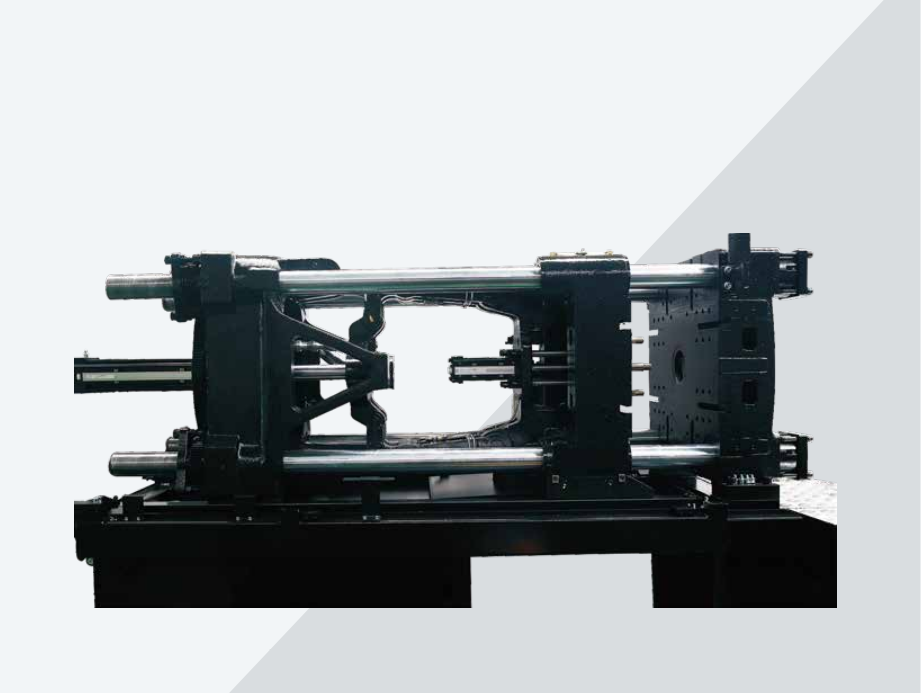

The series' capability to produce complex pipe fittings with high precision makes this special injection molding machine ideal for both UPVC and PPR applications, catering to the evolving needs of the plumbing and construction industries.

UPVC series clamping forces from 2,000 to 7,500 kN.

PPR series clamping forces from 1,600 to 26,000 kN.

UPVC series clamping forces from 2,000 to 7,500 kN.

PPR series clamping forces from 1,600 to 26,000 kN.

More Efficient

More Professional

Customized Design

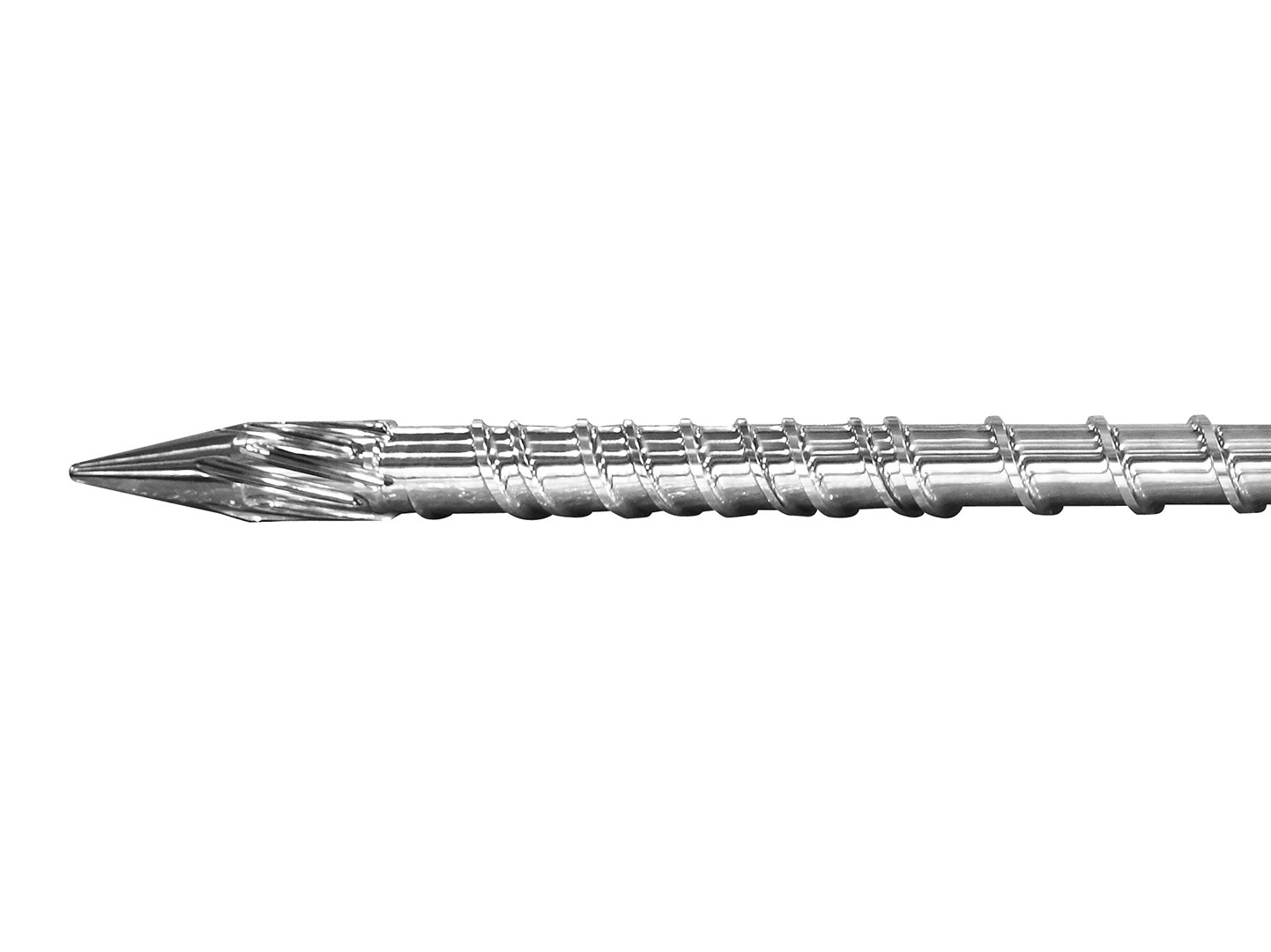

UPVC special plasticizing screw and barrel

- O parafuso e a cuba especiais para UPVC consistem num parafuso com cromagem dura de liga dupla e num flange de bocal com cromagem dura de liga dupla, mais resistentes ao desgaste e à corros?o.

- Permitem obter um efeito de plastifica??o e de mistura de alta qualidade para o fabrico de produtos com superfície lisa.

- Permitem obter um efeito de plastifica??o e de mistura de alta qualidade para o fabrico de produtos com superfície lisa.

Motor de plastifica??o ampliado

A plasticizing motor with an upgraded configuration and increased torque can adapt to UPVC material, which is of high viscosity and poor liquidity, ensuring stable plasticizing.

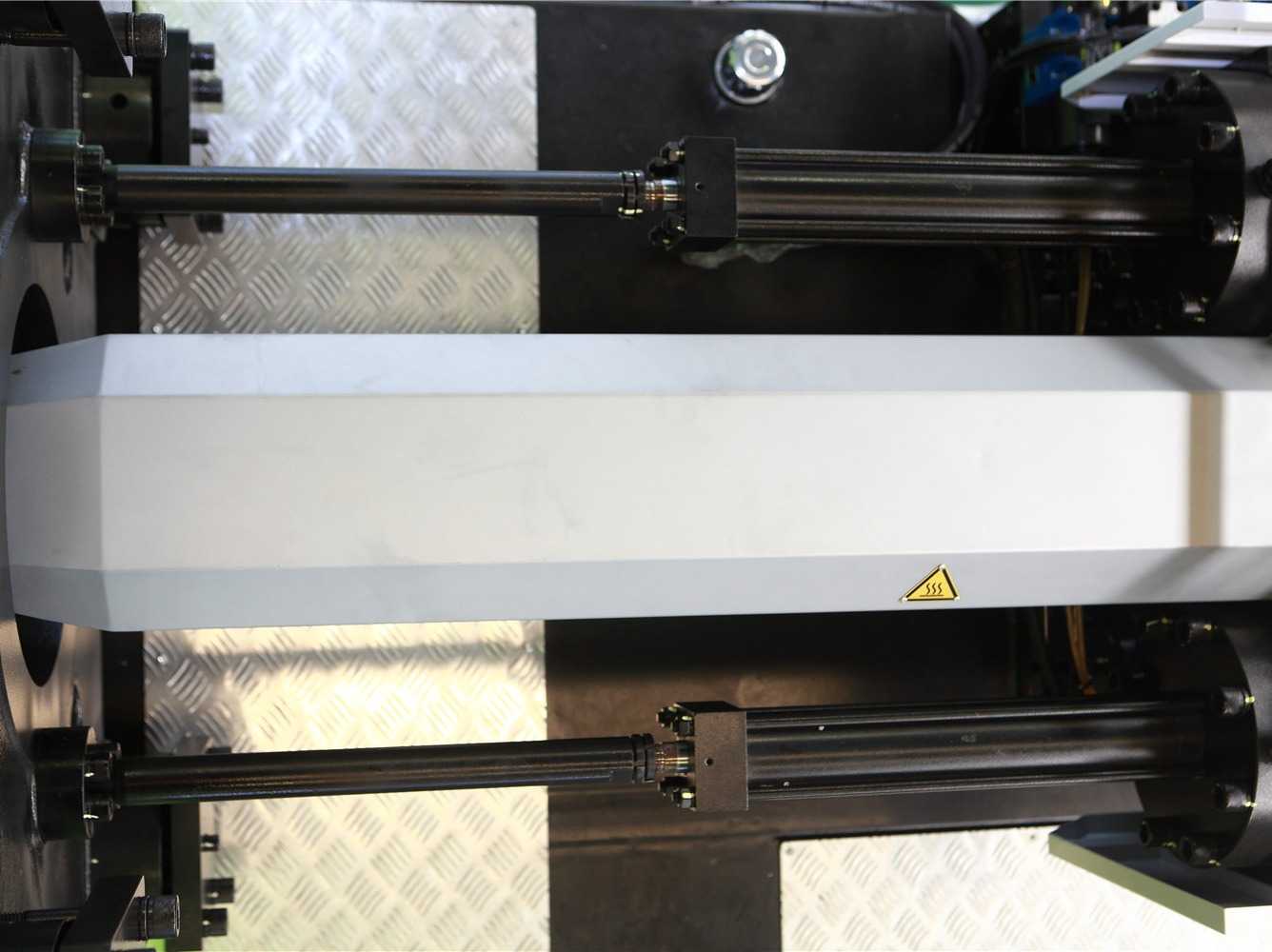

One-piece carriage support + horizontal double-carriage design

Use one-piece carriage support + horizontal double-carriage design to ensure the coaxial alignment between the motion of the injection unit and the force applied on the screw, prevent the rising of nozzle during injection, aintain the clearance between the screw and the barrel, and to avoid dark mark defects due to overheat caused by unilateral shear.

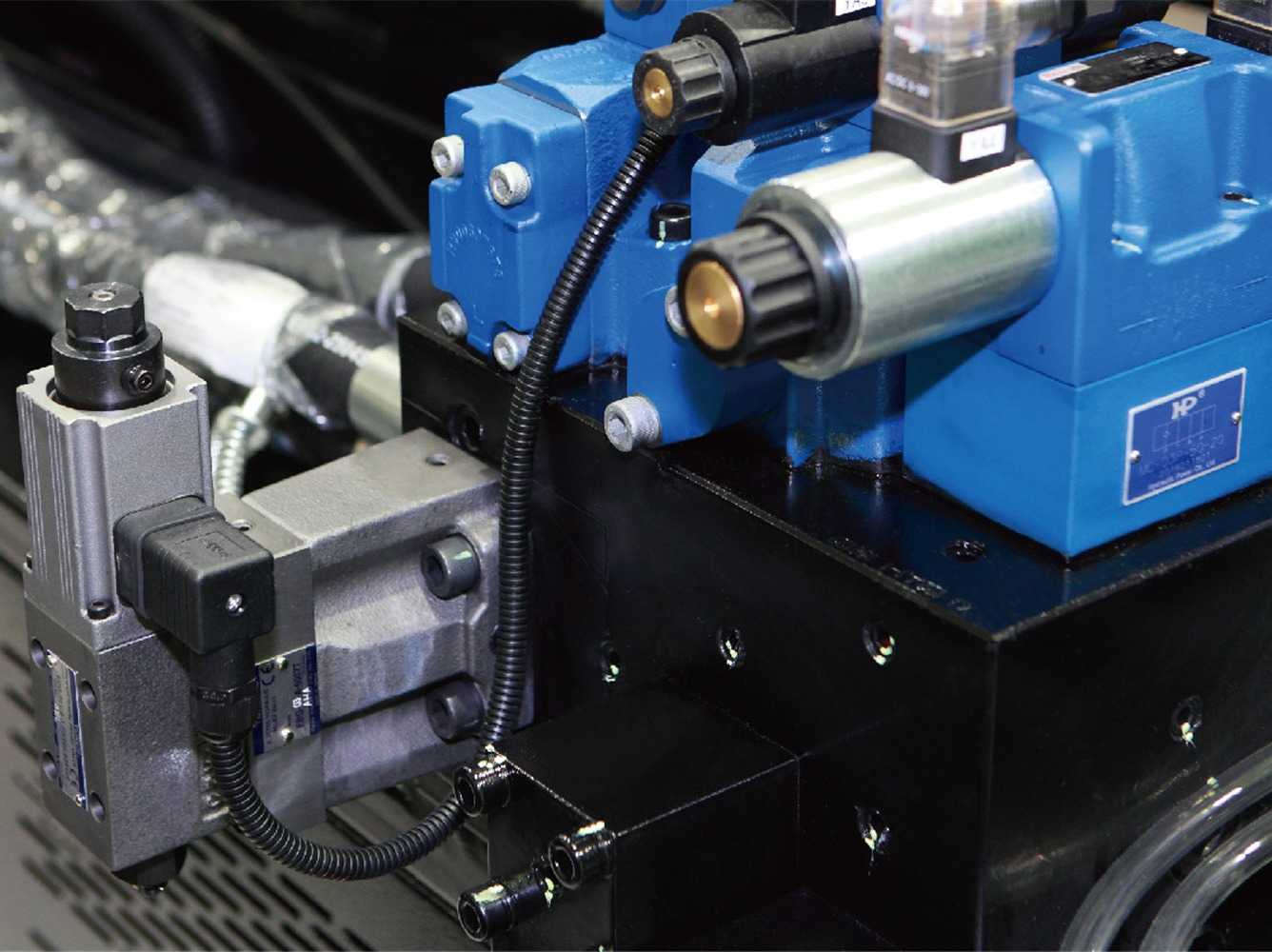

Proportional back pressure control

Use an independent numerically controlled proportional back pressure approach to facilitate precise control by computer and adapt to the thermal sensitivity of UPVC material to shearing heat.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.