Your perfect injection molding partner in the automotive industry

With the change of travel requirements, the development of the automobile manufacturing industry has accelerated, so that the traditional process of injection molding is difficult to satisfy. Therefore, new application solutions have emerged.

As a turnkey solution provider, YIZUMI can become your reliable professional partner with rich experience and excellent quality.

As a turnkey solution provider, YIZUMI can become your reliable professional partner with rich experience and excellent quality.

Why choose us

Yizumi turnkey solution for the production of automotive plastic parts

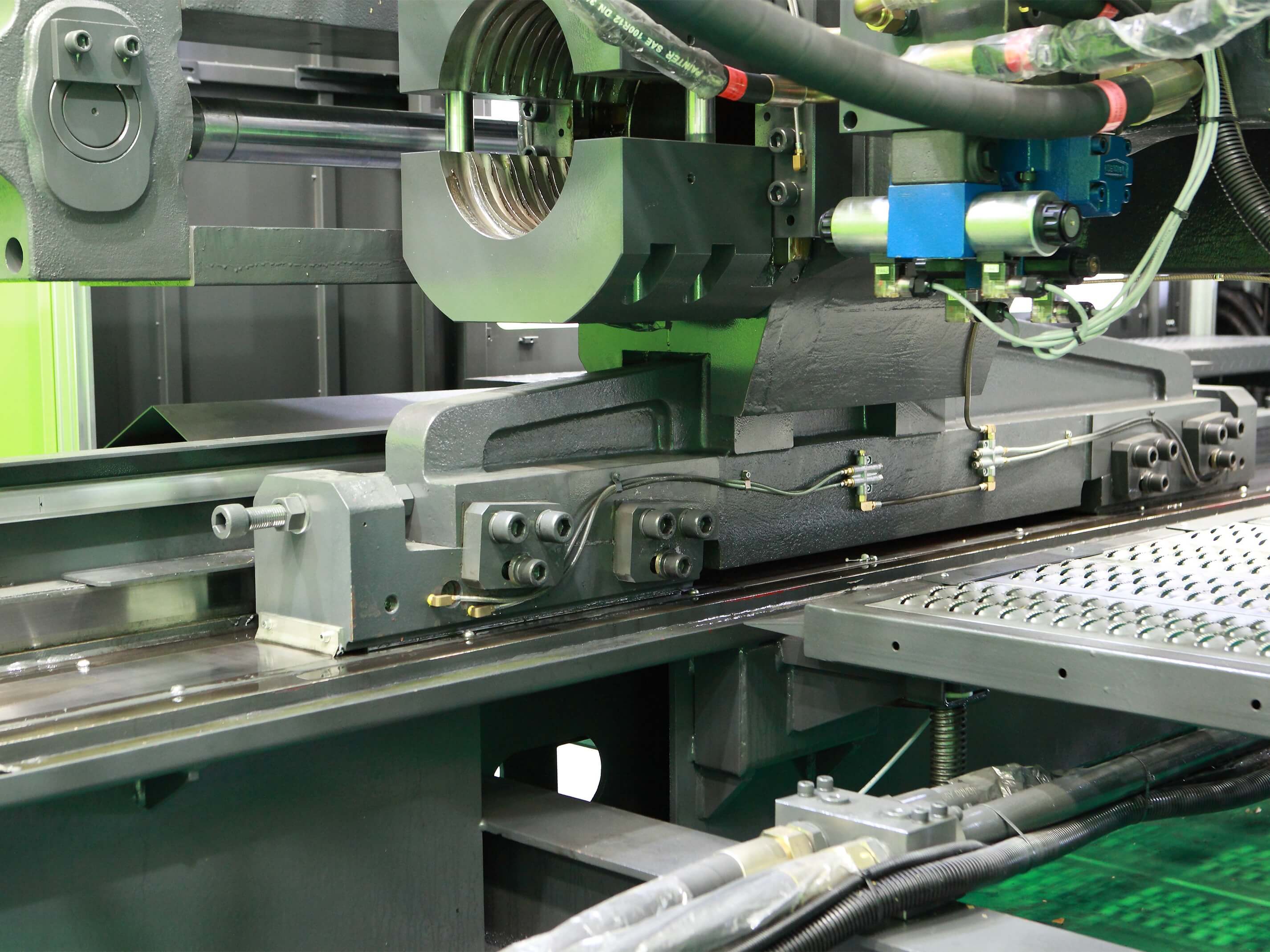

With YIZUMI, you can get a turnkey solution for your automotive production. Not only Yizumi machines, automation, and peripheral equipment, but also our service team would provide continuous support for your production. Yizumi also offers professional suggestions on product design, application of process technology, and process management to better ensure your smooth production and business

Process expertise for all requirements

We help you succeed. There are many different plastic applications used in automobiles. From bumpers (in addition to attractive design, they also meet high crash standards) to lightweight rigid organic panels, high-quality optical lenses, and optical conductors as structural components, to modern interior components with excellent tactile and optical characteristics and additional functions. No matter what kind of challenging components you produce, our application technology experts can ensure that you get the necessary parts and process quality.

Application

Relevant Recommendation

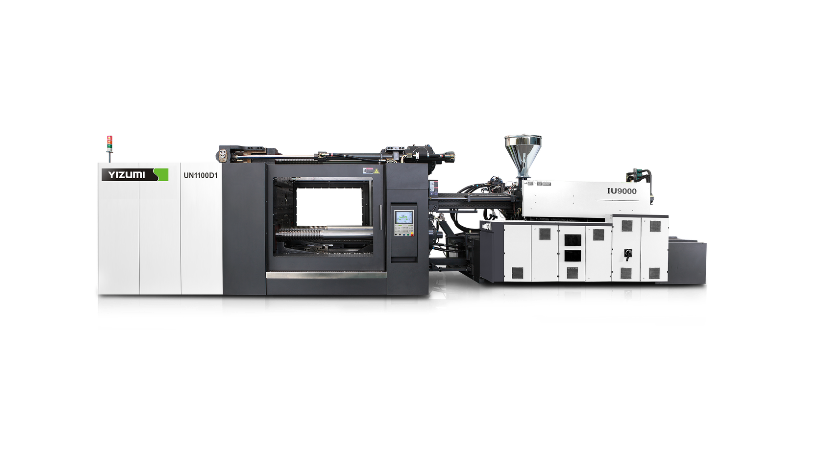

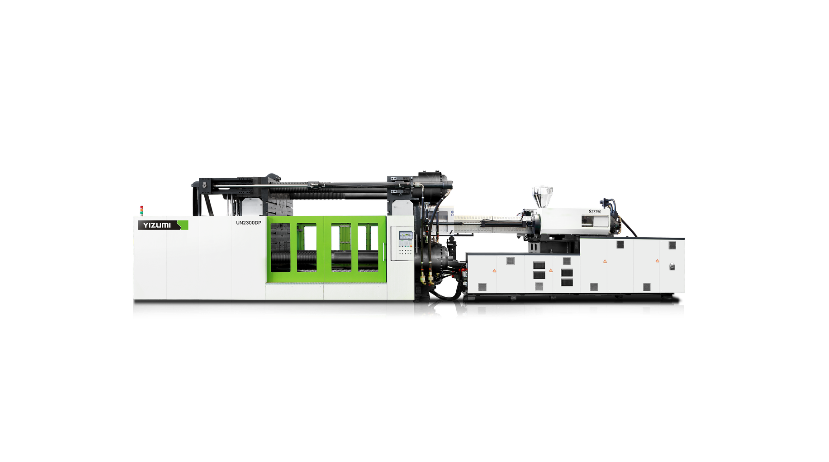

Relevant Products

Relevant Technologies

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Why choose us

Application

Relevant Recommendation

Contact Us

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.