Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

Multi-component Injection Molding Machine

C-NTW Series High-end Multi-component Injection Molding Machine

YIZUMI C Series multi-component injection molding machine is tailored for an era that craves enhanced quality of life and individualization. Emphasizing its core values of stability and customization, the Custom Series pledges to infuse vibrancy and diversity into our everyday lives. Available with clamping forces from 1,600 to 4,800 kN.

Stability

Customization

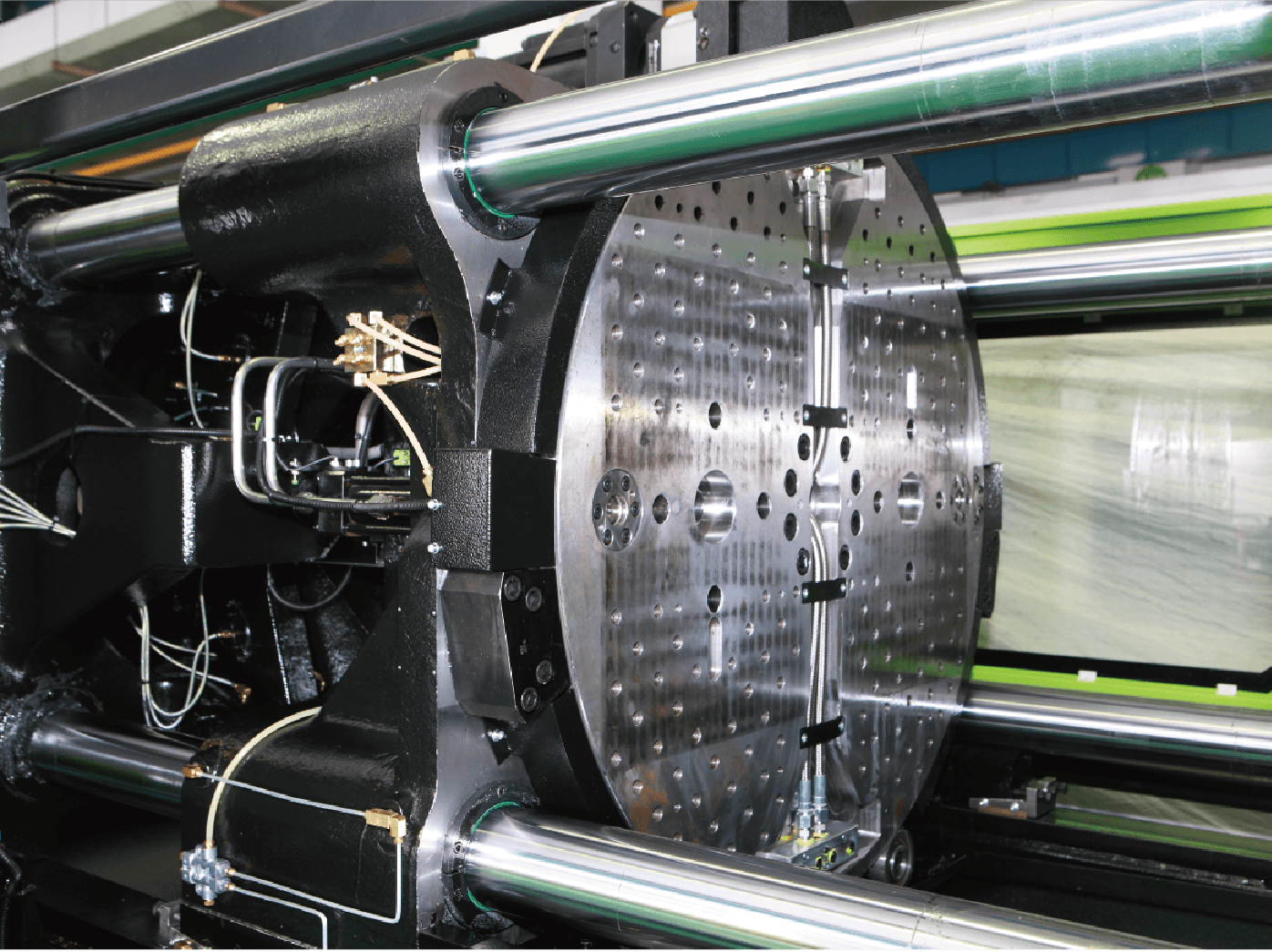

Clamping Unit

High-rigidity T-slot platen

- High-rigidity platen design of all series machines increases the overall rigidity of the clamping unit by 30%.

- High-rigidity T-slot platen brings convenience for installation and removal of mold, reduces the wear of the thread due to long-term use of the screw hole, and extends the life of the platen.

- High-rigidity T-slot platen brings convenience for installation and removal of mold, reduces the wear of the thread due to long-term use of the screw hole, and extends the life of the platen.

Mold opening and closing with proportional valves

Improve the repeatability of mold opening and stability of low-pressure mold protection.

Digital closed-loop positioning control technology

The DCPC technology enables the turntable to rotate smoothly without impact and position accurately.

Injection Unit

Adjustable nozzle center distance

- The stacking injection unit design allows for adjusting the minimum distance of nozzles between the injection units.

- Different standard adjustable ranges of different tonnages to meet the use requirements of molds with various center distances.

- Different standard adjustable ranges of different tonnages to meet the use requirements of molds with various center distances.

Standard numerically controlled proportional back pressure

To provide the necessary conditions for the optimal plasticizing state of plastic melt.

Integrated linear guide rail structure

The injection unit is equipped with a one-piece supporting base, which is integrated with linear guide rails, which minimizes the friction to motion, increases injection accuracy, and enhances plasticizing efficiency.

L/V Independent Injection Unit

Independent V injection unit

- Independent V-type injection unit adopts an independent modular design to meet the combination needs of injection molding machines of different tonnages.

- With YIZUMI's optimization design, the removal of the injection unit provides more mold height for convenient installation and disassembly of molds.

- With YIZUMI's optimization design, the removal of the injection unit provides more mold height for convenient installation and disassembly of molds.

Independent L injection unit

- Independent L-type injection unit adopts an independent modular design to meet the combination needs of injection molding machines of different tonnages and different brands.

- The flexible injection unit is convenient for use, providing a series of functions including core pulling, sequential valve, hot runner, and synchronous action.

- The flexible injection unit is convenient for use, providing a series of functions including core pulling, sequential valve, hot runner, and synchronous action.

Powerful, responsive, user-friendly HMI Control System

The Austrian KEBA2980 computer is characterized by a user-friendly interface and fast response. The powerful functions offered by the KEBA system are ideal for the various molding process solutions of multi-component machines.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.