Machine Introduction Video

Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

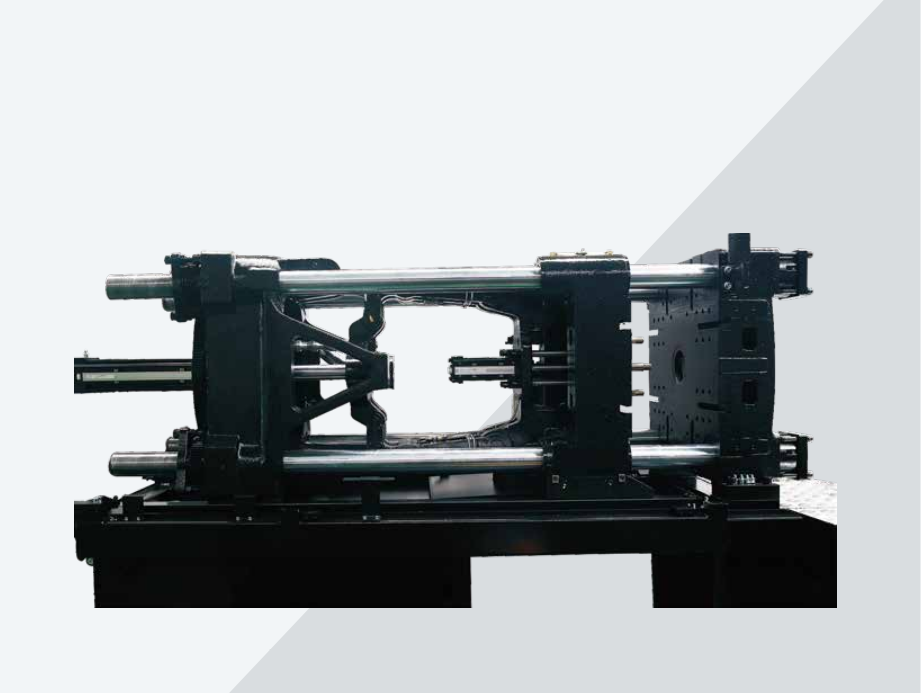

Toggle-clamping Hydraulic Injection Molding Machine

Next-Gen A6 Series Advanced And Intelligent Injection Molding Machine

The A6 series Injection Molding Machine, built with YIZUMI's "IPD 2.0" process, delivers precision molding, energy efficiency, and intelligent technology. It ensures high productivity with clamping forces ranging from 900-10,000 kN.

Intelligence

Green

Precision

Efficiency

Machine Introduction Video

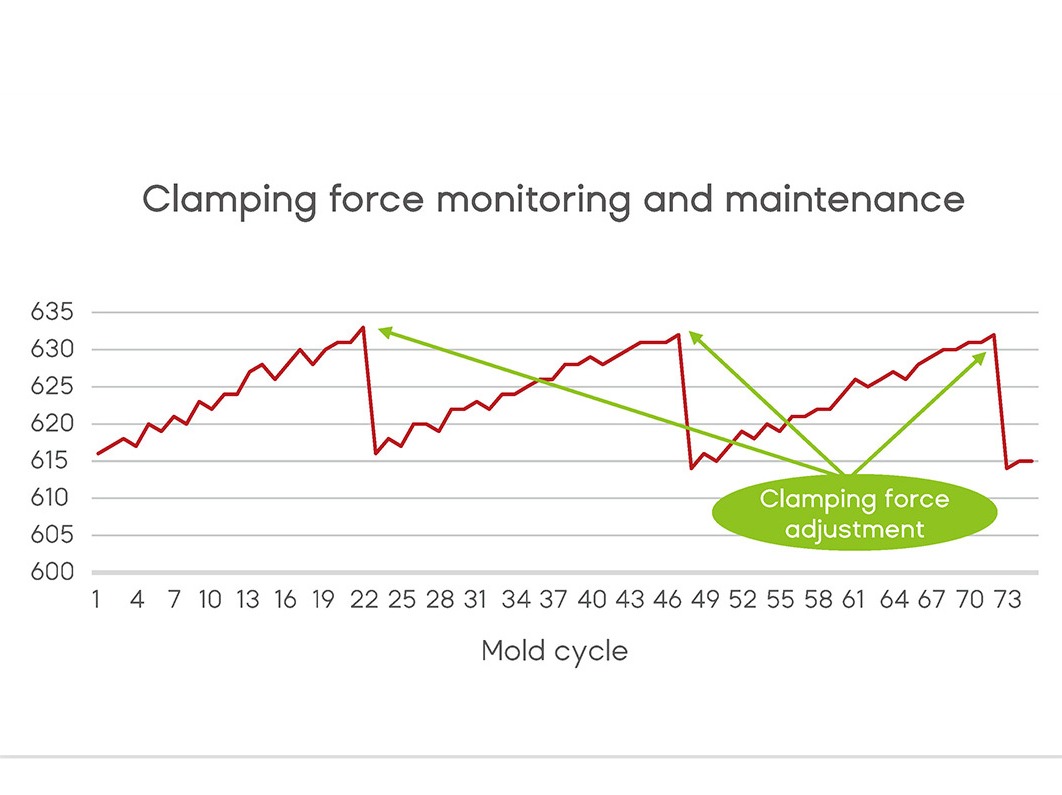

Intelligent clamping force management system

- A6 series is equipped with an intelligent clamping force management system, YIZUMI's advanced intelligent R&D innovation.

- Intelligent clamping force management system proactively identifies and sets optimal clamping force, monitors and intelligently optimizes clamping force parameters, enabling users to efficiently and conveniently operate the injection molding machine while improving the stability of product quality.

- Standard functions of the intelligent clamping force management system:

① Clamping force monitoring

② Intelligent clamping force maintenance

③ Pre-releasing of clamping force

- Intelligent clamping force management system proactively identifies and sets optimal clamping force, monitors and intelligently optimizes clamping force parameters, enabling users to efficiently and conveniently operate the injection molding machine while improving the stability of product quality.

- Standard functions of the intelligent clamping force management system:

① Clamping force monitoring

② Intelligent clamping force maintenance

③ Pre-releasing of clamping force

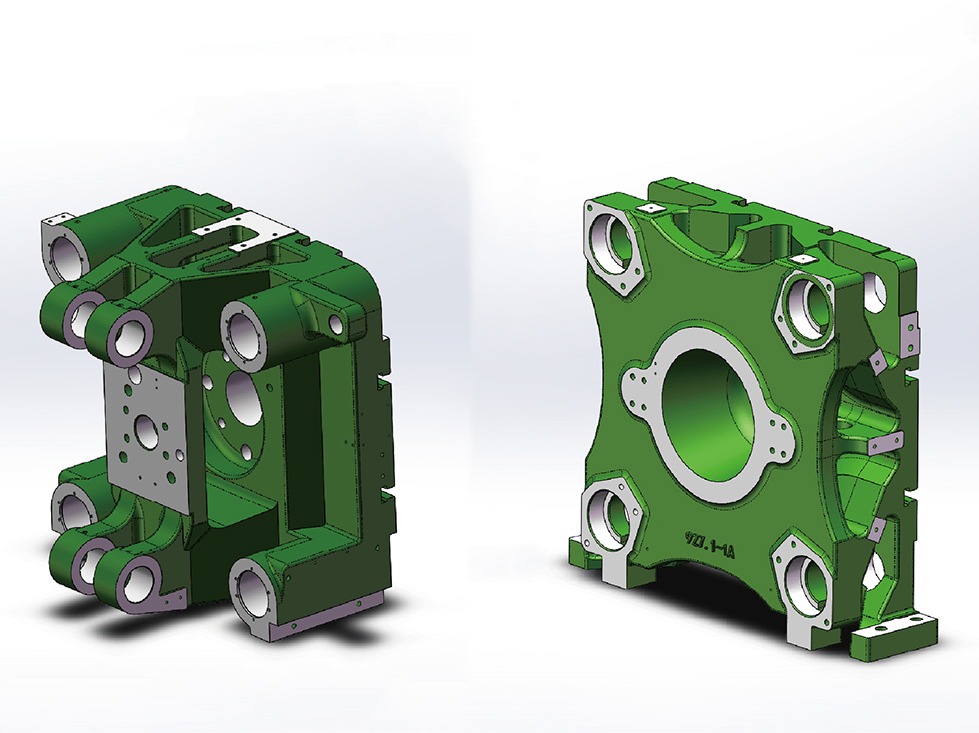

Dual pressure-center platens

- Increased molding precision — optimized design decreases overall deformation of fixed and movable platens by 10% to 25%, resulting in reduced stress on platens during clamping and significantly less cavity deformation.

- Improved utilization of clamping force — effectively addresses problems like flash and low product consistency, while allowing the high-strength, low-deformation structure to employ a lower clamping force for stable clamping.

- Extended service life of mold and equipment — enhanced strength, lightweight structure, and reduced clamping force minimize wear on molds and machines, resulting in less maintenance and longer service life.

- With the "Intelligent clamping force optimization" function, the equipment can sustain the optimal clamping force, making operation more effortless, reliable, and stable.

- Improved utilization of clamping force — effectively addresses problems like flash and low product consistency, while allowing the high-strength, low-deformation structure to employ a lower clamping force for stable clamping.

- Extended service life of mold and equipment — enhanced strength, lightweight structure, and reduced clamping force minimize wear on molds and machines, resulting in less maintenance and longer service life.

- With the "Intelligent clamping force optimization" function, the equipment can sustain the optimal clamping force, making operation more effortless, reliable, and stable.

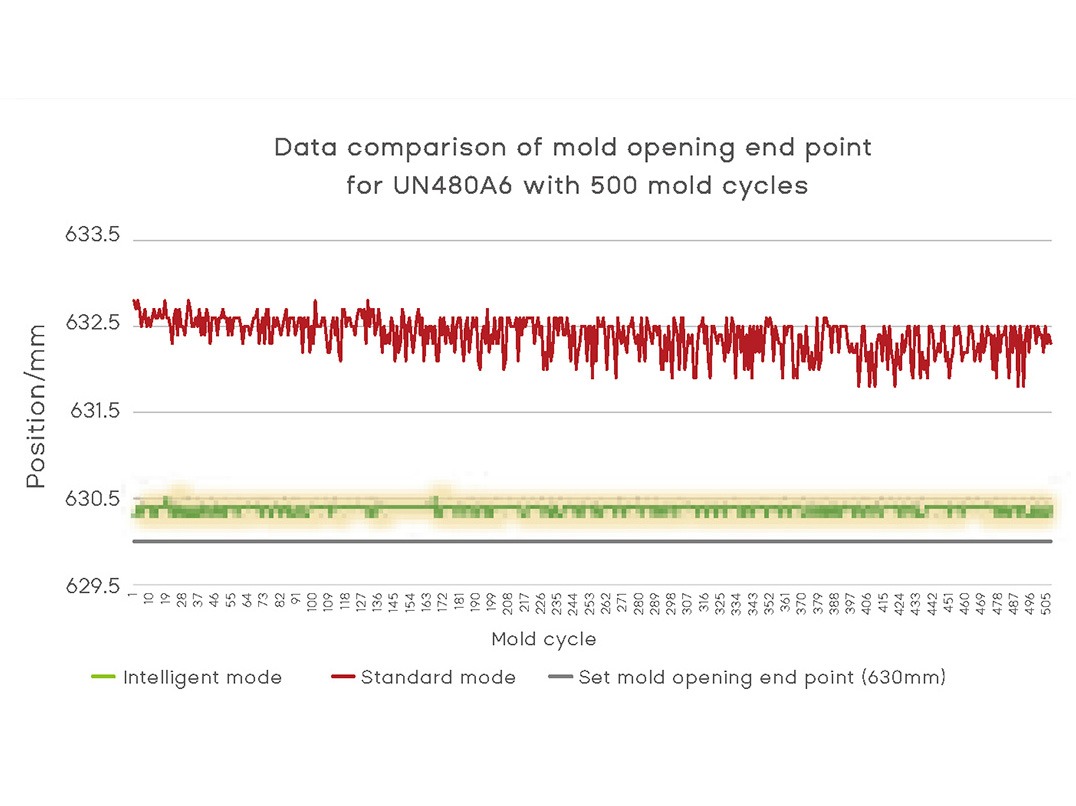

Intelligent mold opening

- Intelligent mold-opening function is a standard feature, which can be activated and adjusted based on production requirements.

- Mold-opening parameter setting is simplified, requiring only two settings: the start and end points.

- Automatic generation and optimization of parameters for the mold-opening process, for smoother operation. Precise mold-opening positioning, achieving accuracy of 0-1mm.

- Mold-opening parameter setting is simplified, requiring only two settings: the start and end points.

- Automatic generation and optimization of parameters for the mold-opening process, for smoother operation. Precise mold-opening positioning, achieving accuracy of 0-1mm.

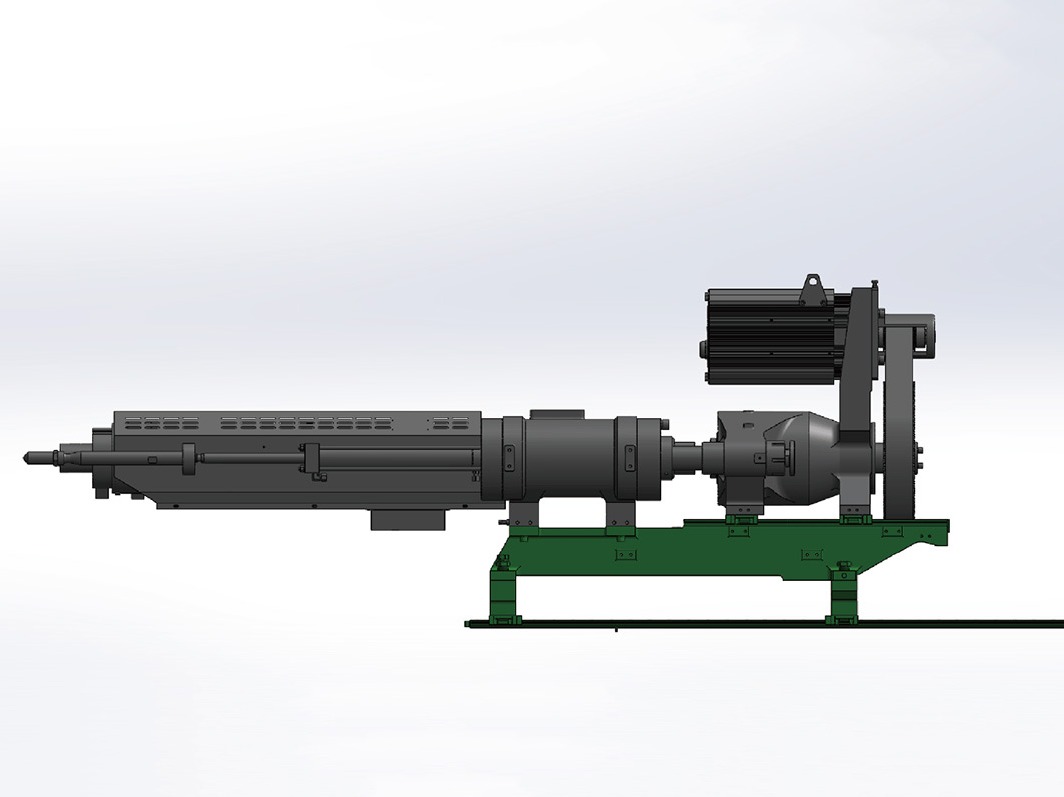

Integral dual-layer support for injection unit

A6 series features integral dual-layer support for the injection unit as a standard configuration, with dual linear guides

for both carriage and injection.

- Lower resistance in the injection process improves energy efficiency; faster response, more accurate control.

- Oil-free self-lubricating linear guides, over 800 km of lubrication, improving machine cleanliness and ease of maintenance.

for both carriage and injection.

- Lower resistance in the injection process improves energy efficiency; faster response, more accurate control.

- Oil-free self-lubricating linear guides, over 800 km of lubrication, improving machine cleanliness and ease of maintenance.

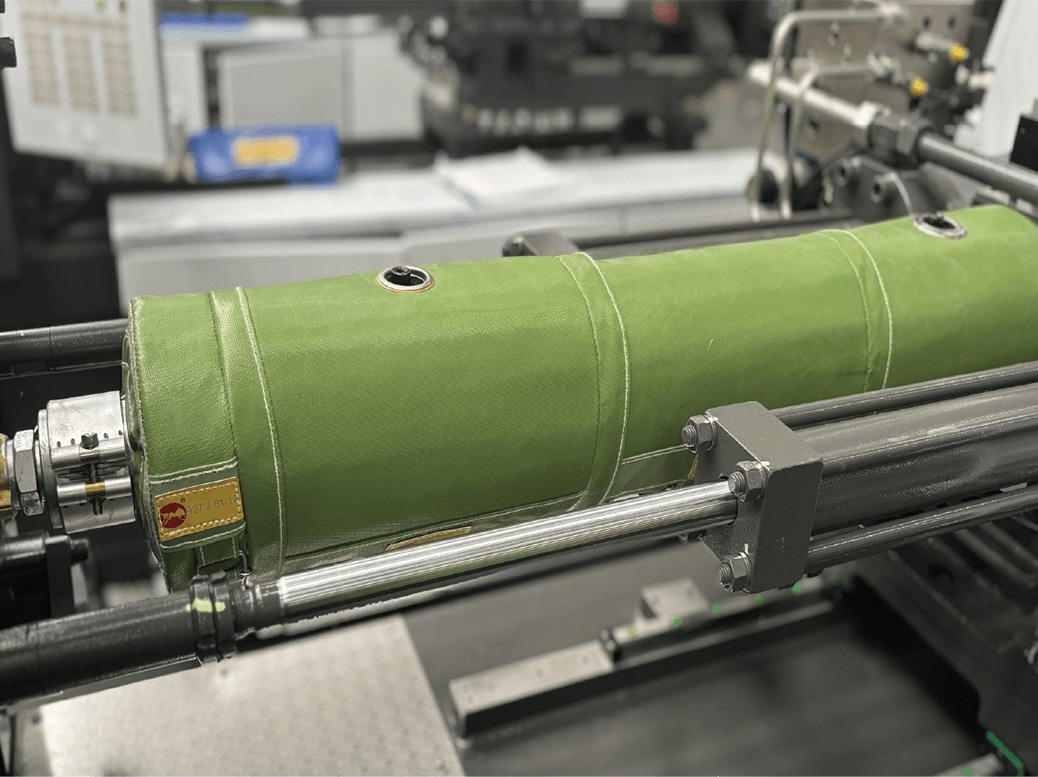

Fully enclosed aerogel insulation device

- The A6 series introduces an upgraded insulation system with a fully enclosed design and optimized structure, utilizing aerogel material with exceptional thermal insulation capabilities. This upgrade extends the longevity and significantly improves energy efficiency.

- In tests on the UN160A6 model, a fully enclosed aerogel insulation device (standard feature) maintains a constant temperature of 240°C for one hour, achieving about 40% energy saving compared to conventional insulation systems

- In tests on the UN160A6 model, a fully enclosed aerogel insulation device (standard feature) maintains a constant temperature of 240°C for one hour, achieving about 40% energy saving compared to conventional insulation systems

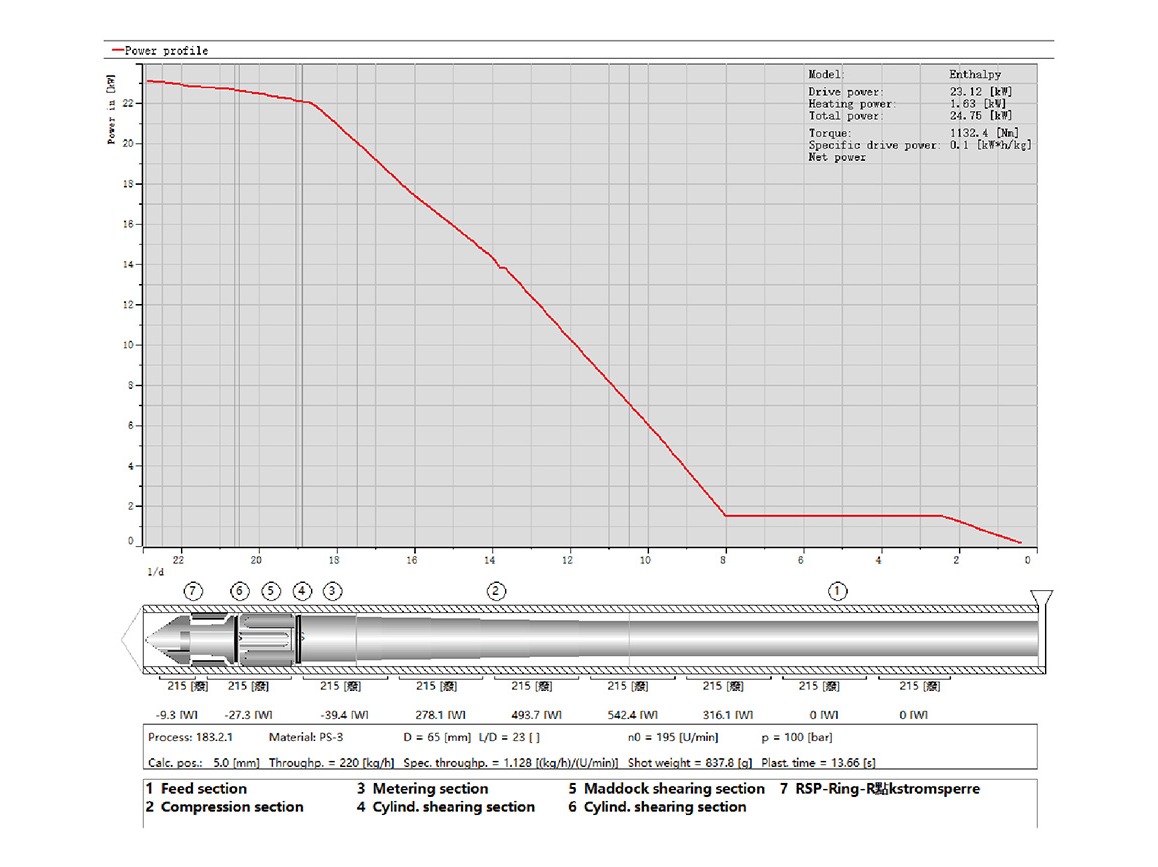

High-mixing dual-alloy plasticizing components for all models

- A6 series is equipped with high-mixing dual-alloy plasticizing components as standard, greatly enhancing wear resistance.

- The screw is designed with simulation technology to optimize plasticizing performance.

- The structure optimization of screw head, check ring and screw washer ensures higher injection weight repeatability.

- The screw is designed with simulation technology to optimize plasticizing performance.

- The structure optimization of screw head, check ring and screw washer ensures higher injection weight repeatability.

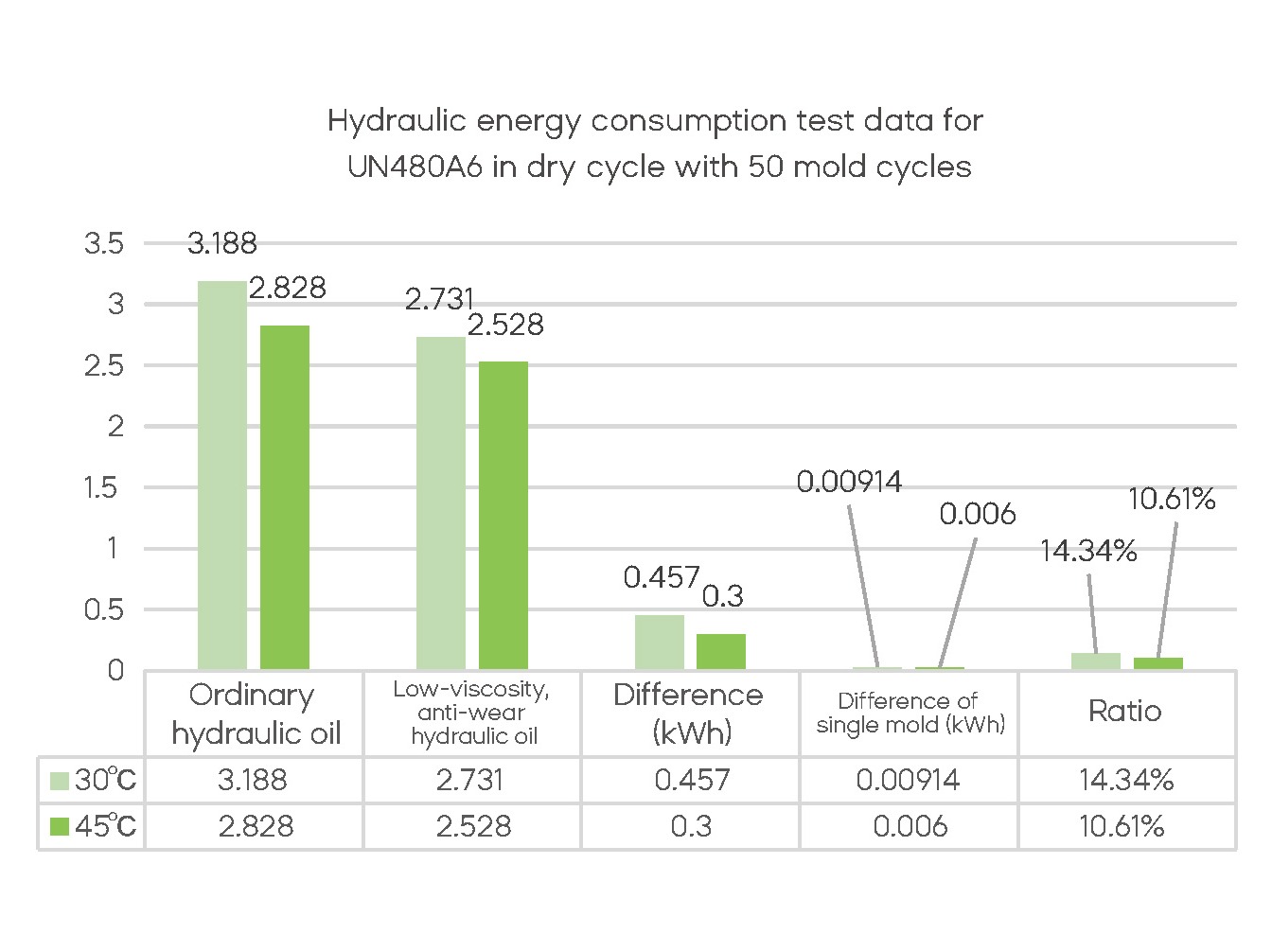

New energy-efficient hydraulic system

A6 series is equipped with a new energy-efficient hydraulic system, achieving an average energy saving of over 12%.

- The newly optimized hydraulic manifold channels and pipelines reduce pressure loss and minimize energy consumption.

- By using new low-viscosity, anti-wear hydraulic oil, the system delivers over 10% energy savings in the dry cycle test.

- The newly optimized hydraulic manifold channels and pipelines reduce pressure loss and minimize energy consumption.

- By using new low-viscosity, anti-wear hydraulic oil, the system delivers over 10% energy savings in the dry cycle test.

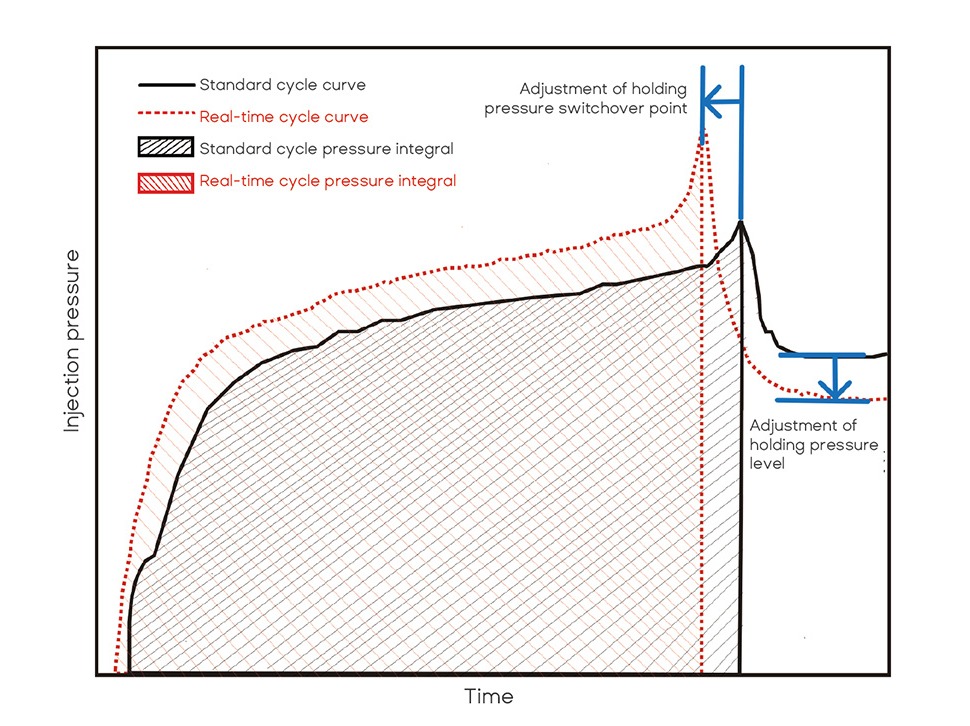

Intelligent weight V/P control

- Intelligent weight V/P control function, YIZUMI’s core R&D achievement for all models, achieves product weight repeatability of 2 ‰.

- In the production process, the controller monitors the pressure variations of plasticizing and uses algorithms to automatically adjust the holding pressure switchover point or the holding pressure, ensuring precise repeatability of product weight.

- Holding pressure switchover control of consistent shot weight: For molds with short holding time, holding pressure switchover control with consistent shot weight performs better.

- Holding pressure control of consistent compression of melting material: For molds with longer holding times, holding pressure control of consistent compression of melting material provides superior performance.

- In the production process, the controller monitors the pressure variations of plasticizing and uses algorithms to automatically adjust the holding pressure switchover point or the holding pressure, ensuring precise repeatability of product weight.

- Holding pressure switchover control of consistent shot weight: For molds with short holding time, holding pressure switchover control with consistent shot weight performs better.

- Holding pressure control of consistent compression of melting material: For molds with longer holding times, holding pressure control of consistent compression of melting material provides superior performance.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.