Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

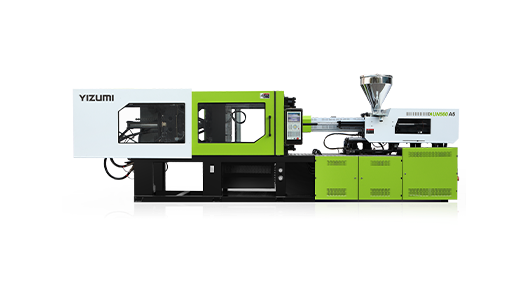

Toggle-clamping Hydraulic Injection Molding Machine

U3 Series Bakelite Special Injection Molding Machine

YIZUMI introduces an integrated feeding system for a cleaner production environment. Our turnkey solution includes raw materials, molds, equipment, and processes. This Hydraulic Toggle-Clamp Bakelite Injection Molding Machine is available with clamping forces from 900 to 4,800 kN.

High cost-effective

High stability

High integration

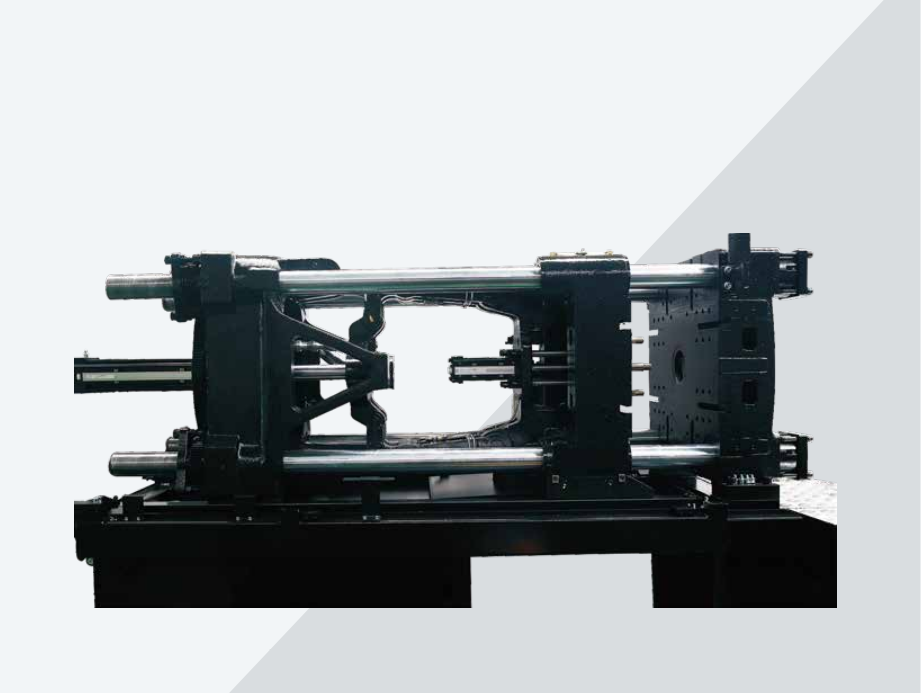

Uniform-stress clamping technology

Both the fixed and movable platen design adopts uniform-stress clamping technology, less platen deformation. Uniform distribution of clamping force between mold and platen can prevent flash, parts missing, and other undesirable defects, thus reducing he mold clamping force and extending the useful life of the platen.

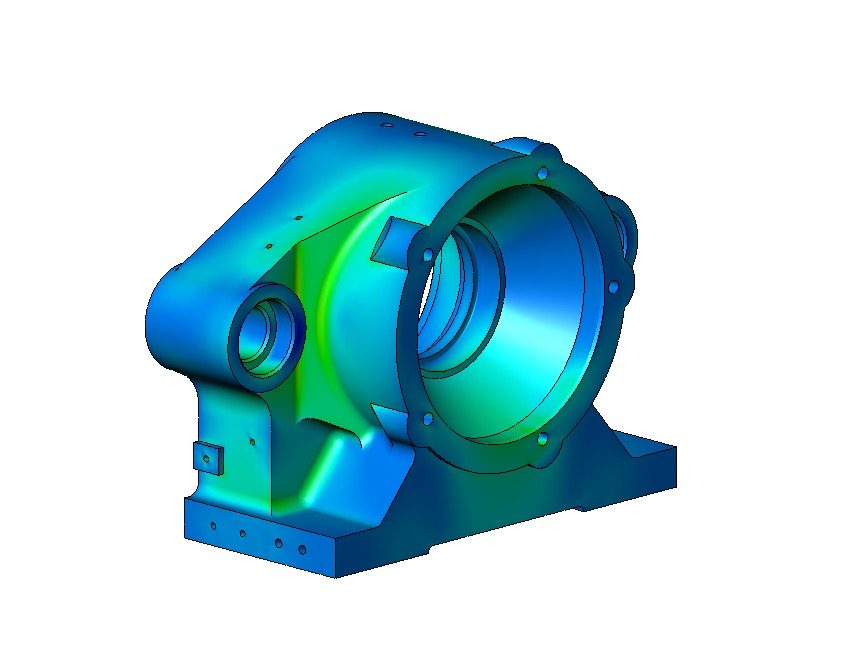

Optimized injection unit

UN90-480U1 series injection molding machine adopts a single-carriage injection unit. Optimized injection unit not only improves its rigidity, but also ensures coaxiality between the movement direction of the injection unit and injection force, reducing the resistance and improving the injection stability and accuracy.

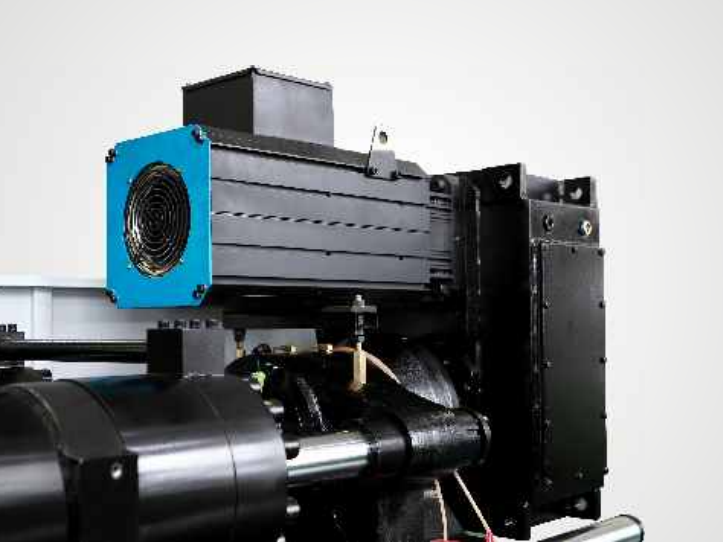

YIZUMI 3rd Generation Servo Energy-saving Technology

The 3rd generation energy-saving servo system is adopted, which has a small moment of inertia, no bottom flow, and lower energy consumption. The whole oil circuit is optimized in multiple ways, realizing the reduction in movement resistance and pressure flow loss during machine operation, to ensure lower power consumption of the complete machine.

MS control system

- The control unit adopts a Cortex-A55 processor with a scan time of 0.25ms, speedy response, and accurate control.

- 1000 sets of mold data memory, USB port for extension of storage.

- 7+1 sections of PID temperature control support switchover between type J and type K thermocouples. Automatic PID tuning improves the temperature control accuracy.

- 1000 sets of mold data memory, USB port for extension of storage.

- 7+1 sections of PID temperature control support switchover between type J and type K thermocouples. Automatic PID tuning improves the temperature control accuracy.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.