Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

Special-usage Injection Molding Machine

SPET Series Injection Molding Machine For PET Products

Designed for PET bottle preforms, cosmetics, and daily storage items, the SPET Series Injection Molding Machines deliver efficiency and value for PET product manufacturers. Enhanced screw speed boosts plasticizing capacity by 5–10%, while standard electric plasticizing cuts energy use by 10–30%. Flexible injection unit configurations adapt to diverse product needs. Clamping forces range from 1,600 to 10,000?kN.

Highly-efficient

Energy-saving

Professional

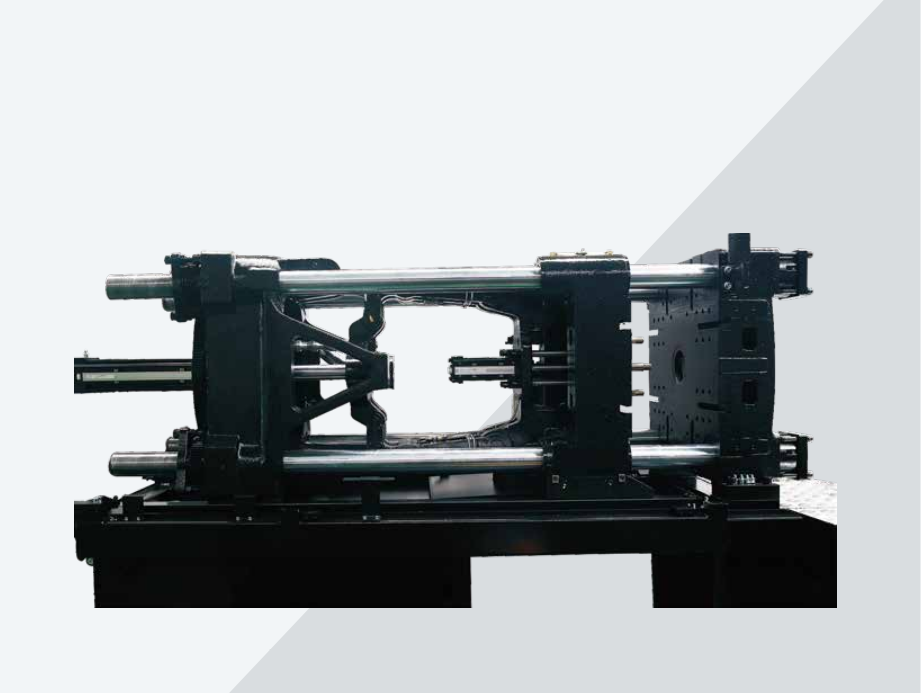

New-Generation Clamping Unit

Strong central support to the movable platen structure

- Movable platen with strong central support minimizes platen deformation, achieving even distribution of clamping force.

- Lower clamping force to reduce deformation of mold cavity, improve product molding accuracy, and save energy.

- Lower clamping force to reduce deformation of mold cavity, improve product molding accuracy, and save energy.

Highly rigid fixed platen and tail platen structure

Optimization of fixed platen and tail platen structure to enhance rigidity and reduce deformation.

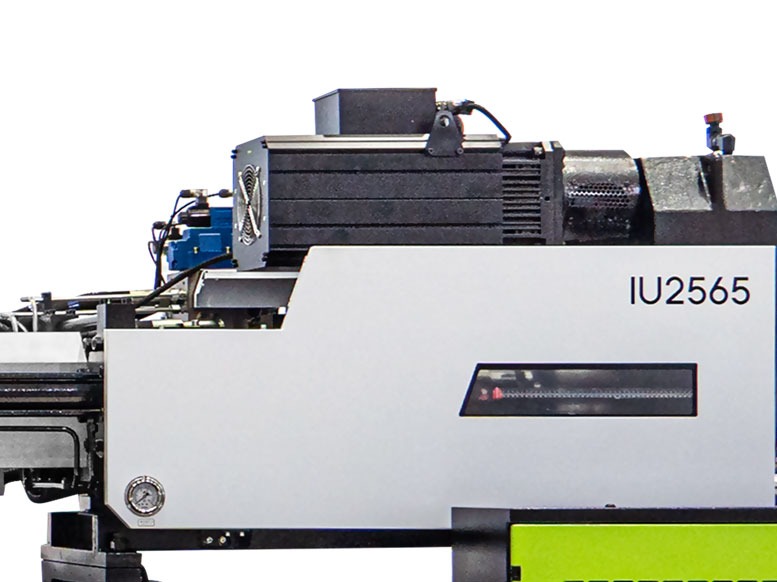

Injection System

- The injection unit features dual linear guides with self-lubricating function, ensuring a clean and tidy operation.

- With oil change interval of over 5 years, it minimizes oil contamination in the workshop and the environment.

- With oil change interval of over 5 years, it minimizes oil contamination in the workshop and the environment.

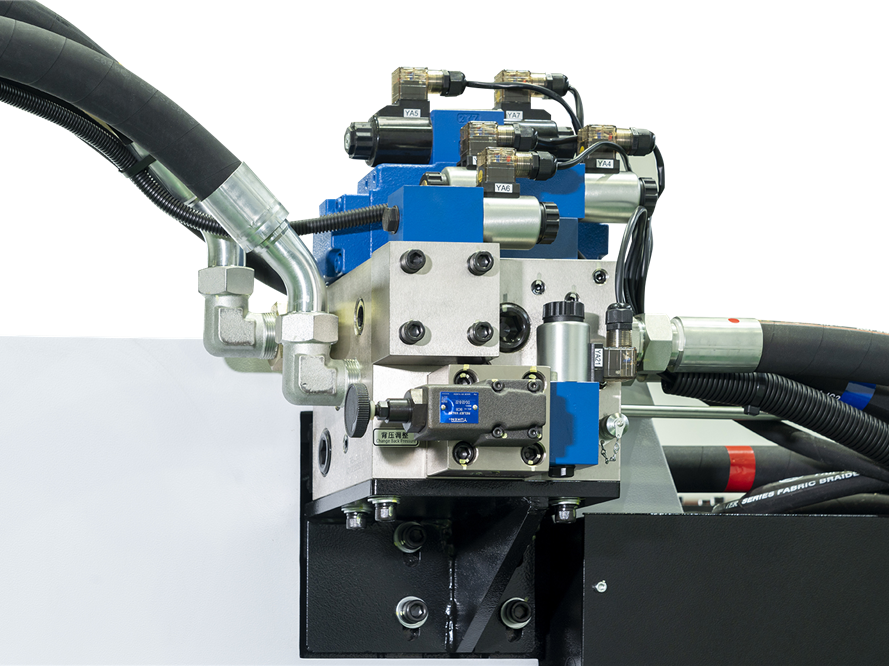

All-new hydraulic circuit design

- Optimized oil circuit design for lower pressure loss.

- More accurate mold-open positioning.

- More accurate mold-open positioning.

Upgraded control system

3- Expandable with multiple modules including AO, AI, DO, DI, and TM to meet more requirements.

- Real-time monitoring of signals from machine equipped sensors to coordinate corresponding movements for higher operating safety.

- Support common RS232/485 communication interface, CANOPEN, Ethernet port, temperature compensation sensor connector, and USB port.

-15-stage linear control on speed offers more precise control. Accurate response to 1% flow. More usefriendly parameter adjustment.

- Real-time monitoring of signals from machine equipped sensors to coordinate corresponding movements for higher operating safety.

- Support common RS232/485 communication interface, CANOPEN, Ethernet port, temperature compensation sensor connector, and USB port.

-15-stage linear control on speed offers more precise control. Accurate response to 1% flow. More usefriendly parameter adjustment.

Energy consumption management system (optional)

- Cumulative energy consumption monitoring display of total electricity usage from the start of operation until the present.

- Energy consumption display of previous production cycle.

- Instantaneous power display of real-time power consumption.

- Energy consumption display of previous production cycle.

- Instantaneous power display of real-time power consumption.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.