Home

Products & Solutions

Polymer Process

Injection Molding Solutions

Product

High-speed Injection Molding Machine

P-M Series High-speed Injection Molding Machine

YIZUMI P-M Series high-speed injection molding machines offer up to 500mm/s injection, precise clamping, and reliable cleanroom production for superior quality.

Suitable for clean room production

High injection speed

High-rigidity

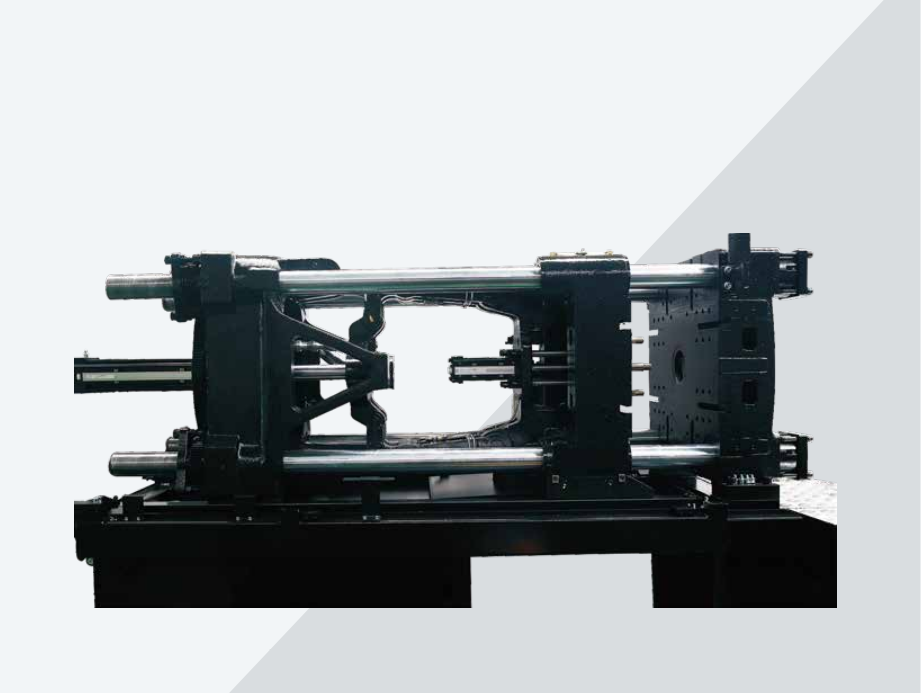

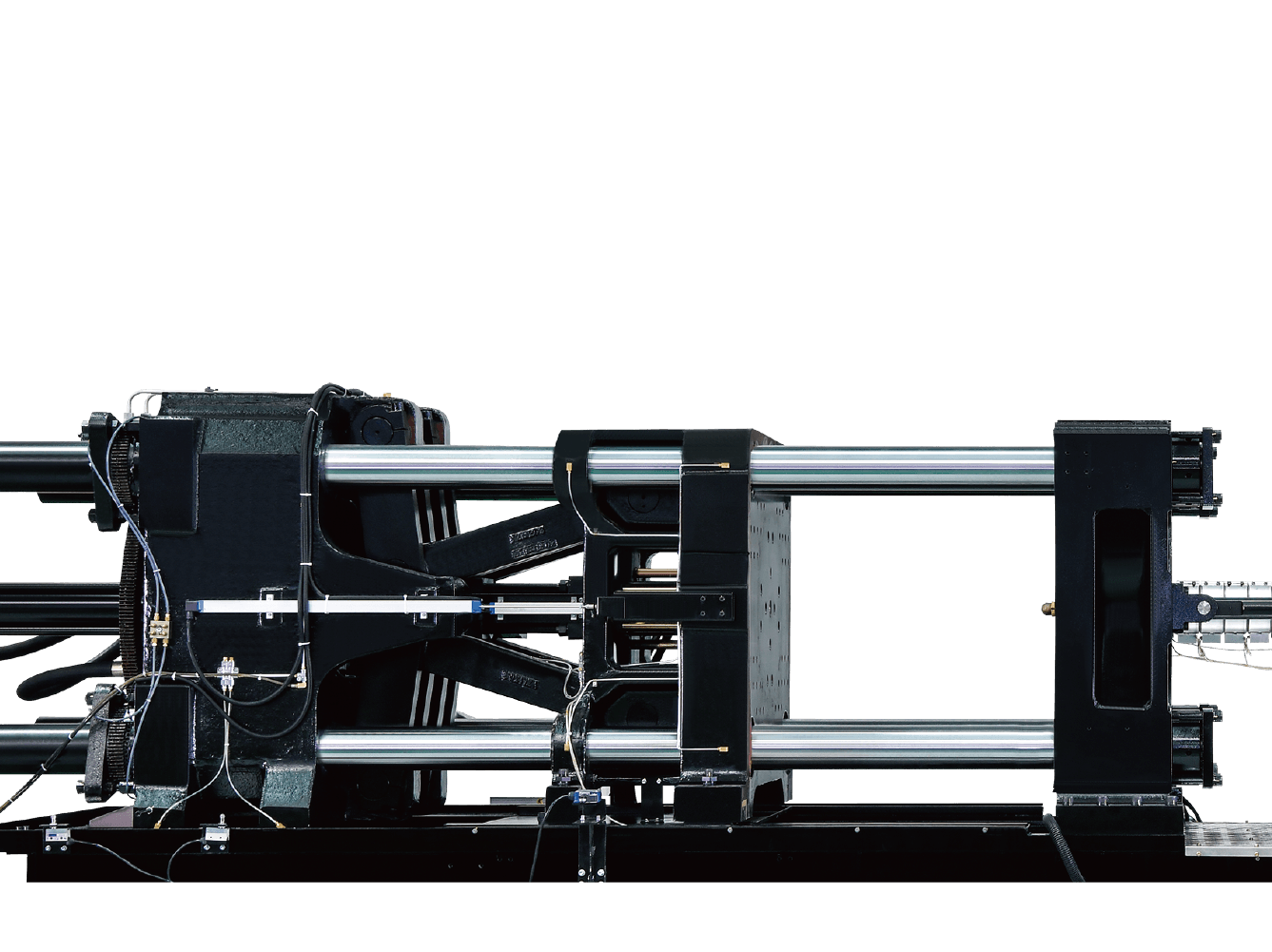

High-strength toggle

- Enhance the strength and rigidity of the toggle, to extend the machine service life and improve the operation stability of the machine under high speed and high strength;

- Large inward toggle reduces platen deformation and effectively ensures product quality.

- Large inward toggle reduces platen deformation and effectively ensures product quality.

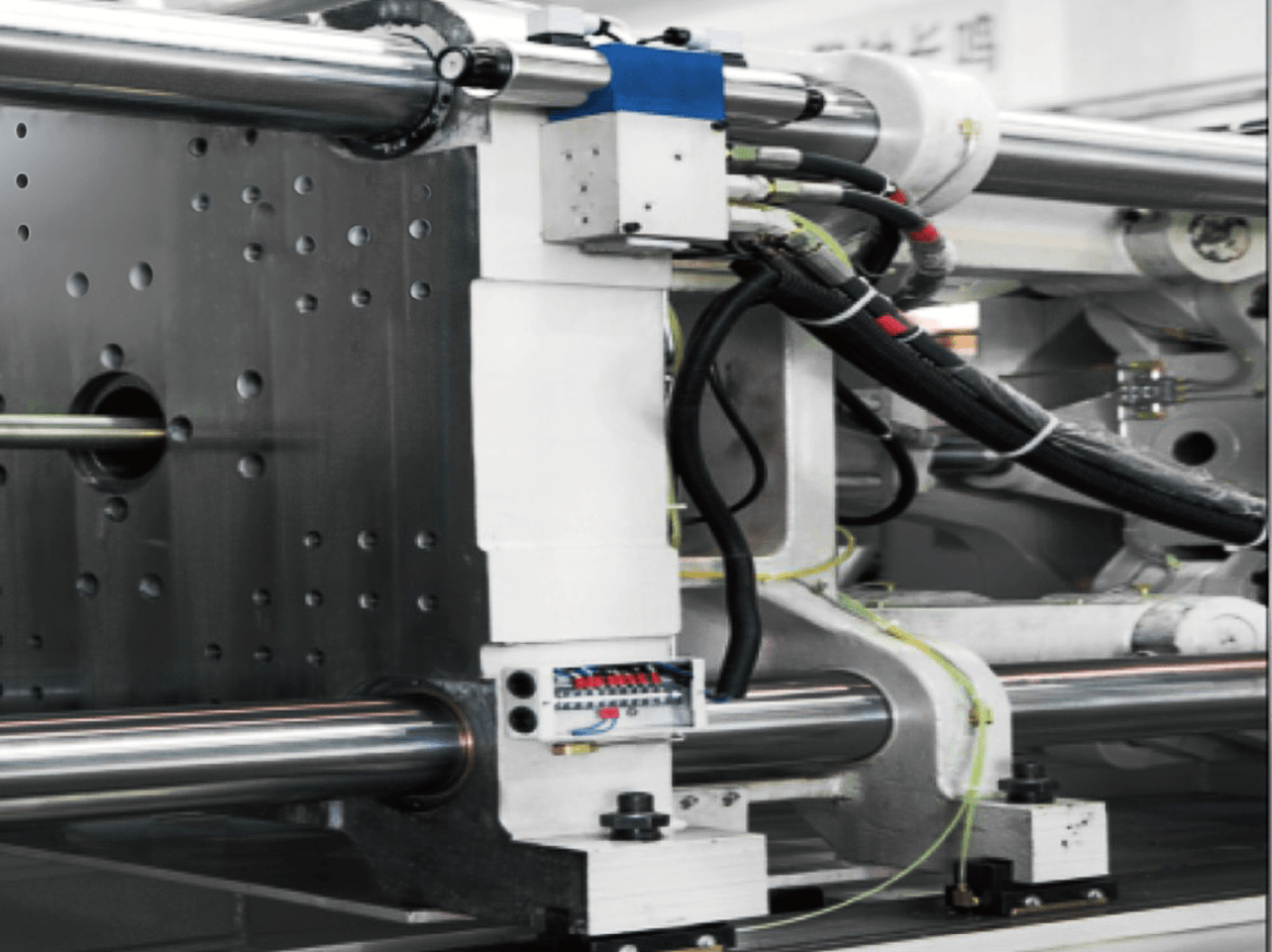

High-rigidity clamping unit

Suitable for a large length-diameter ratio or deep cavity product, it can significantly improve the clamping force and better protect the mold.

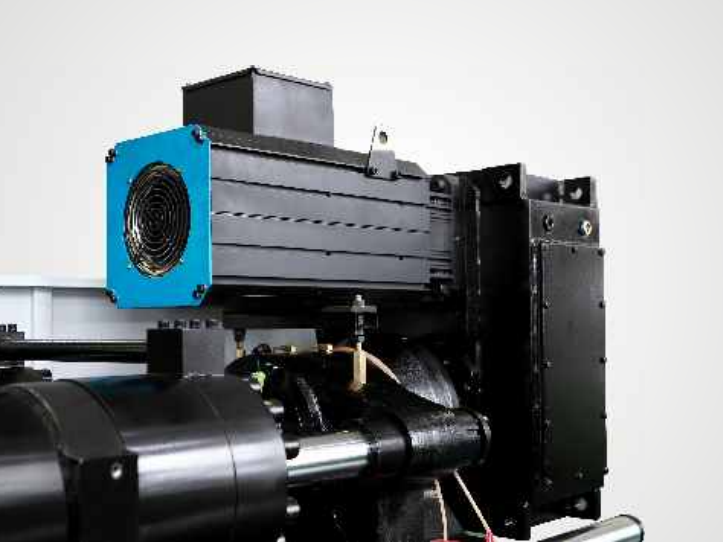

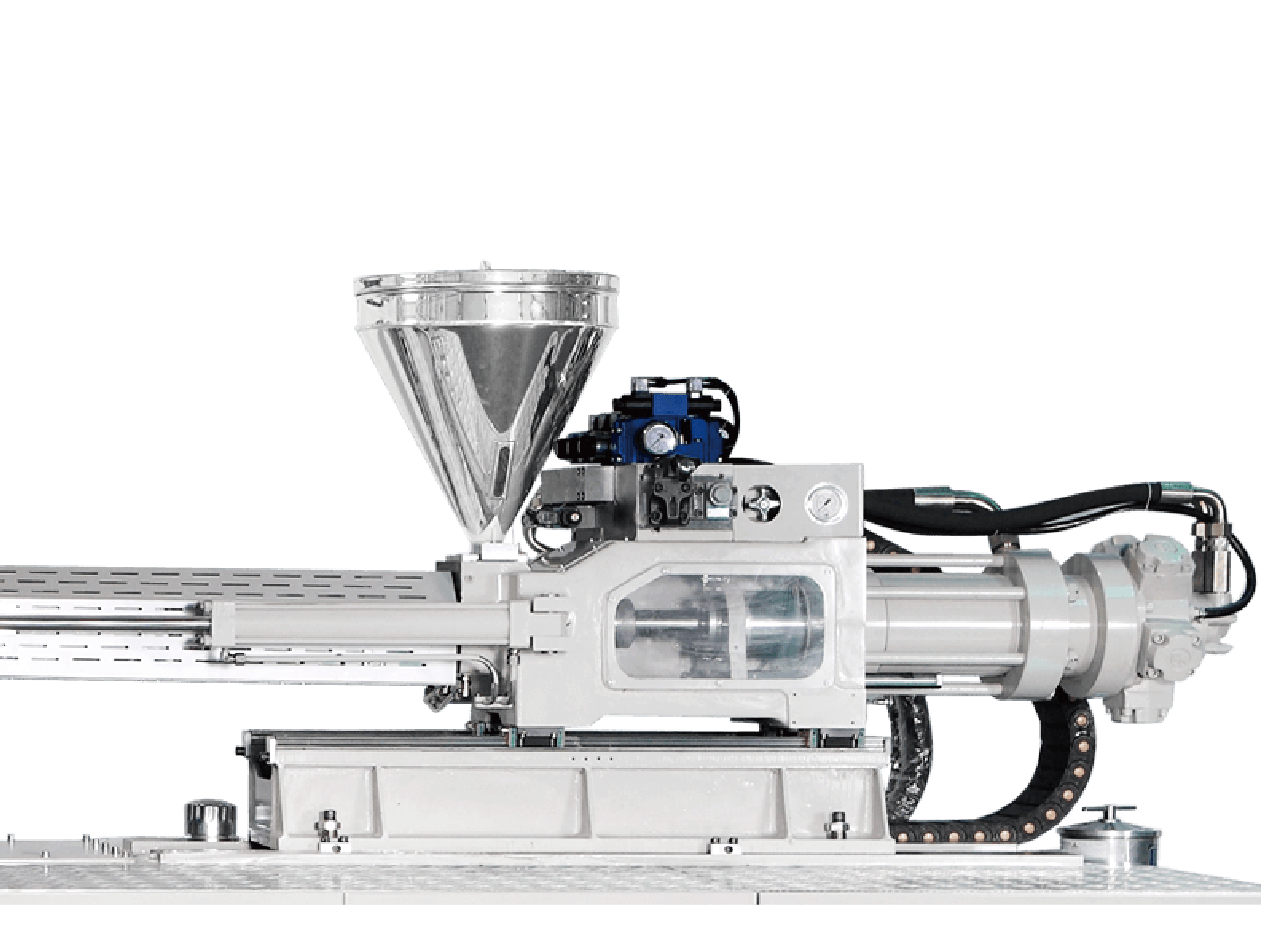

Single-cylinder injection system

- The maximum injection speed is up to 500mm/s (Optional);

- It can be equipped with an electric injection unit to improve the injection accuracy and speed, and achieve synchronous plasticizing (Optional);

- Equipped with a screw of large length-diameter ratio to improve plasticizing efficiency.

- It can be equipped with an electric injection unit to improve the injection accuracy and speed, and achieve synchronous plasticizing (Optional);

- Equipped with a screw of large length-diameter ratio to improve plasticizing efficiency.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Processes

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.