Modern LSR Molding Equipment for Cost-Effective & High-Quality Silicone Production

Abstract:

Modern LSR molding equipment is no longer just a production tool—it is a strategic investment for businesses that prioritize quality, efficiency, and cost-effectiveness. The YIZUMI LSR Series Liquid Silicone Injection Molding Machine exemplifies the next generation of silicone processing technology, combining precision, stability, and operational flexibility. With advanced injection systems, accurate material blending, and user-friendly controls, this machine delivers consistent high-quality silicone products while optimizing production efficiency.

Liquid silicone rubber (LSR) has become a critical material across industries, from medical devices and automotive components to electronics and household products. Its unique properties, including flexibility, heat resistance, and durability, make it ideal for high-performance applications.

Achieving consistent quality in silicone products, however, depends heavily on the injection molding equipment used. Businesses looking for cost-effective, precise, and reliable solutions are increasingly turning to LSR molding equipment like the YIZUMI LSR series liquid silicone injection molding machine.

Understanding LSR Molding Equipment

LSR molding equipment is specialized machinery designed for processing liquid silicone rubber through injection molding. Unlike traditional thermoplastics, liquid silicone requires careful handling due to its high fluidity, sensitivity to heat, and curing process. Modern liquid silicone injection machines combine precision engineering with advanced automation to ensure uniform material distribution, accurate vulcanization, and minimal waste.

Liquid Silicone Injection Molding Machine Applications

Key considerations when evaluating LSR molding equipment include:

Injection precision: Accurate dosing of components A and B is critical to avoid defects such as bubbles, color inconsistencies, or incomplete curing.

Temperature control: Proper mold heating ensures consistent vulcanization and prevents premature curing in the nozzle or mold.

Material handling: Efficient mixing and feeding systems reduce waste and enhance repeatability.

Operational stability: High-performance machines minimize downtime and ensure long-term production efficiency.

Modern LSR molding machines are designed to meet these requirements, offering businesses the reliability needed for high-volume and high-precision silicone production.

Advantages of Liquid Silicone Injection Machines

Adopting a liquid silicone rubber injection machine offers several advantages for industrial manufacturers:

Enhanced Product Quality

The precise control over mixing, injection pressure, and mold temperature ensures consistent product dimensions, surface finish, and mechanical properties. This is particularly important for applications in the medical and automotive industries, where tolerances are tight and product reliability is critical.

Reduced Material Waste

Modern LSR machines integrate efficient material feeding and metering systems that minimize leftover silicone, ensuring more cost-effective production. High repeatability also reduces scrap rates caused by defects or inconsistent curing.

Improved Production Efficiency

Automated mixing, injection, and curing systems accelerate production cycles, allowing manufacturers to meet growing market demand without compromising quality. Features such as quick-change molds and real-time monitoring further enhance operational efficiency.

Customization and Flexibility

Many LSR molding machines are modular, allowing businesses to adapt the equipment for specific production requirements. From nozzle types to auxiliary feeders and screw configurations, machines can be tailored to optimize both soft and hard thermoset plastic processing.

LSR Molding Equipment For Auto Parts

Applications of LSR Molding Equipment

LSR molding equipment is widely used across industries due to the versatile properties of liquid silicone rubber. Some common applications include:

Medical Devices: Catheters, seals, surgical instruments, and tubing benefit from silicone’s biocompatibility and flexibility.

Automotive Components: Gaskets, O-rings, and vibration dampers leverage silicone’s resistance to heat, oil, and environmental stress.

Electronics: Keypads, connectors, and protective covers rely on silicone for durability and insulation.

Consumer Products: Baby bottle nipples, kitchen utensils, and wearable devices utilize silicone for its safety, flexibility, and aesthetic qualities.

The performance and consistency of these products rely heavily on the LSR molding equipment, making investment in advanced machinery a strategic decision for manufacturers.

Choosing the Right LSR Molding Equipment

When selecting an LSR molding machine, businesses should focus on factors that align with their production goals:

Output Volume: Determine the required cycle time and production capacity.

Precision Needs: Evaluate the machine’s injection accuracy and mold temperature control capabilities.

Material Compatibility: Ensure the equipment handles the specific silicone compounds you use, including special additives or colorants.

Ease of Maintenance: Machines with user-friendly designs, minimal leakage, and straightforward cleaning reduce downtime and operational costs.

Support and Customization: A manufacturer that offers tailored solutions and responsive technical support ensures smoother integration into your production line.

By considering these factors, businesses can select LSR molding equipment that maximizes efficiency, reduces costs, and guarantees high-quality output.

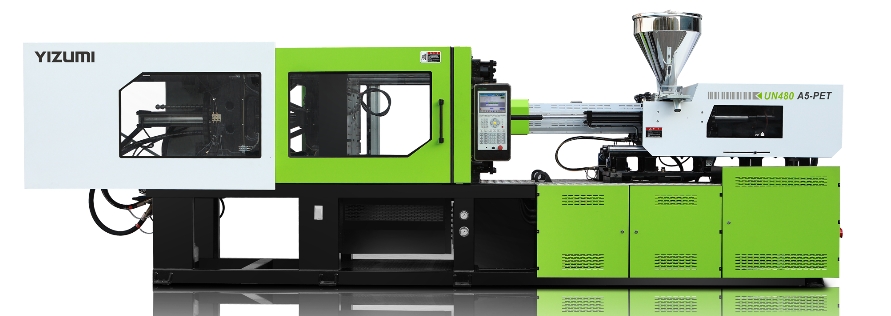

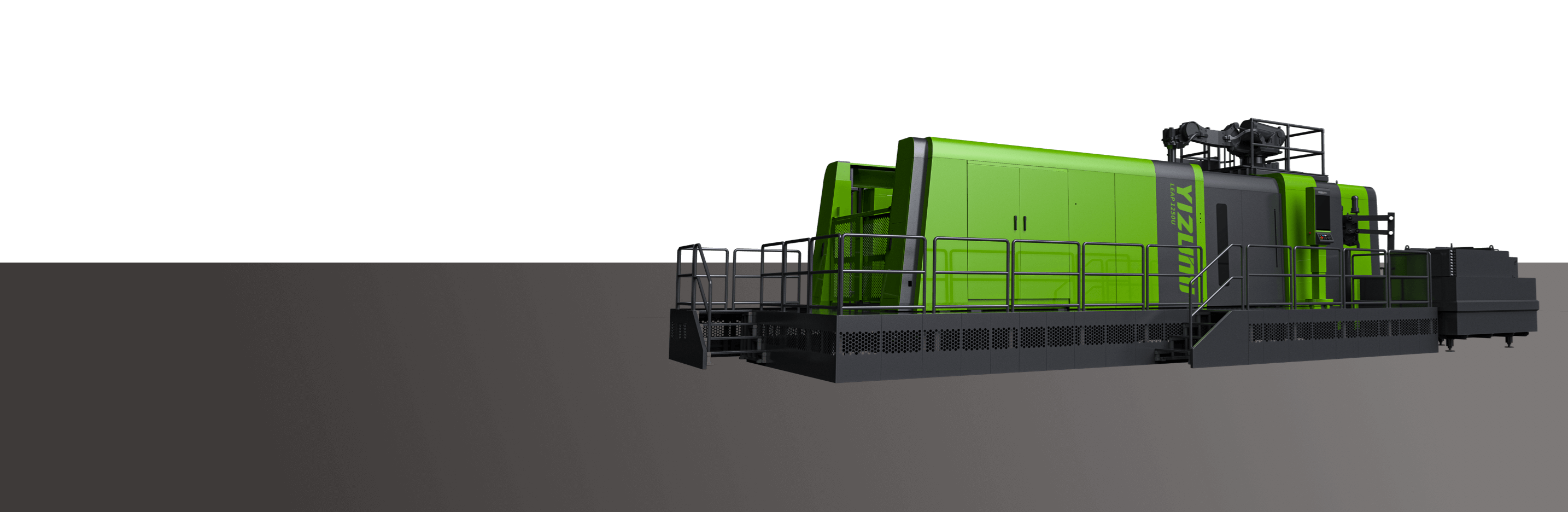

YIZUMI LSR Series Liquid Silicone Injection Molding Machine

The YIZUMI LSR Series Liquid Silicone Injection Molding Machine is engineered for businesses seeking precise, efficient, and high-quality silicone production. Designed to handle both soft liquid silicone and traditional thermoset plastics, this machine integrates a specialized liquid silicone injection unit with YIZUMI’s reliable SKII platform, ensuring consistent performance and stability. Its advanced design supports accurate material blending, rapid vulcanization, and precise solidification, optimizing product yield while reducing material waste.

YIZUMI Liquid Silicone Injection Molding Machine

Key features of the LSR Series liquid silicone injection machine focus on efficiency, professionalism, and customization. A water-cooled pneumatic injection nozzle prevents liquid silicone leakage and eliminates premature curing in the nozzle. The mixing screw ensures full integration of components A and B, while sensitive seal rings minimize leakage during injection start-up. Built-in visualized mold temperature control allows precise adjustments, with separate sockets for each heating unit to enhance operational convenience.

The system includes a fully pneumatic YIZUMI liquid silicone feeder, enabling accurate secondary metering, minimal material waste, and uniform color mixing. Designed for high repeatability and minimal maintenance, the LSR Series liquid silicone rubber injection machine ensures smooth production with fewer defects, making it ideal for industrial applications that demand consistent, top-quality silicone products.

Future Trends in LSR Molding

The demand for high-performance silicone products continues to grow, driving innovation in liquid silicone injection machines. Emerging trends include:

Automation and Industry 4.0 Integration: Real-time monitoring, data analytics, and predictive maintenance improve productivity and reduce defects.

Energy Efficiency: Advanced machines focus on minimizing energy consumption while maintaining high throughput.

Enhanced Precision: New injection systems and screw designs further reduce material waste and improve part consistency.

Sustainable Manufacturing: Environmentally friendly processing and low-waste systems are becoming standard expectations.

Investing in modern LSR molding equipment positions manufacturers to leverage these trends, ensuring competitive advantage and long-term growth.

Conclusion

Modern LSR molding equipment is no longer just a production tool—it is a strategic investment for businesses that prioritize quality, efficiency, and cost-effectiveness. The YIZUMI LSR Series Liquid Silicone Injection Molding Machine exemplifies the next generation of silicone processing technology, combining precision, stability, and operational flexibility. With advanced injection systems, accurate material blending, and user-friendly controls, this machine delivers consistent high-quality silicone products while optimizing production efficiency.

For manufacturers looking to expand their capabilities in medical, automotive, electronics, or consumer product sectors, choosing the right liquid silicone rubber injection machine is crucial. YIZUMI’s LSR series liquid silicone injection machine ensures that businesses not only meet the demands of today’s market but are also prepared for the innovations of tomorrow!