Types of Die Casting Machines: Which One Fits Your Industry Needs?

Abstract:

Hot and cold chamber die casting machines form the core of precision metal manufacturing. Hot chamber machines excel in fast, high-volume production of small parts with low-melting metals, while cold chamber machines handle larger, high-strength components made from aluminum or copper alloys. Secondary methods such as squeeze, low-pressure, and high-pressure die casting offer specialized solutions for strength, surface finish, or production scale.

Die casting machines play a central role in modern manufacturing, enabling the precise production of metal components for automotive, electronics, aerospace, and industrial machinery. Selecting the right type of die casting machine affects productivity, cost efficiency, and part quality. This article provides a detailed guide, focusing primarily on hot chamber and cold chamber die casting machines, with an overview of other types to give a fuller picture.

What is a Die Casting Machine?

A die casting machine is specialized equipment designed to produce metal parts by forcing molten metal into a steel mold under high pressure. The resulting parts are highly accurate, durable, and often feature smooth surface finishes, making die casting an essential manufacturing process for complex shapes and high-volume production.

Key advantages include:

- High production speed

- Precise, repeatable dimensions

- Excellent surface finish

- Reduced material waste

- Ability to manufacture complex geometries

Understanding the types of die casting machines allows manufacturers to align their equipment choice with their material, product size, production volume, and quality requirements.

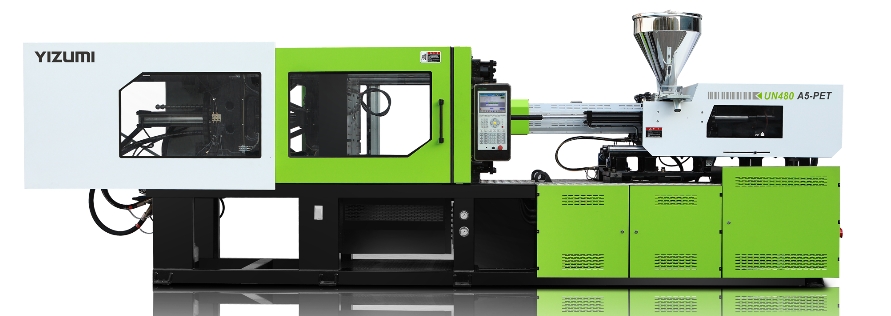

Hot Chamber Die Casting Machine

Hot chamber die casting machines are designed primarily for metals with low melting points, such as zinc, magnesium, and lead. This machine type has a molten metal chamber integrated directly into the machine, allowing rapid metal injection into the die.

YIZUMI Hot Chamber Die Casting Machine

How Hot Chamber Die Casting Works

- The pressure chamber is partially submerged in a molten metal bath.

- A plunger draws molten metal into the cylinder.

- The plunger injects the molten metal into a steel die under high pressure.

- After solidification, the mold opens, and the part is ejected.

This integrated system reduces cycle times, making it highly efficient for mass production.

Advantages of Hot Chamber Machines

High-speed production: Fast injection cycles enable large-scale manufacturing.

Thin-walled part production: Ideal for components requiring minimal thickness without compromising strength.

Excellent surface finish: Produces parts with fine detail and smooth surfaces.

Reduced material waste: Efficient melting and injection processes minimize scrap.

Ideal Applications

Hot chamber die casting machines are best suited for small-to-medium parts where precision and speed are critical. Common applications include:

- Automotive components: carburetors, gear housings

- Electrical connectors and switches

- Consumer electronics housings

- Decorative hardware components

Compatible Materials

- Zinc alloys

- Magnesium alloys

- Lead and tin alloys

Hot chamber machines dominate industries that prioritize high-volume output and high-precision small parts with consistent quality.

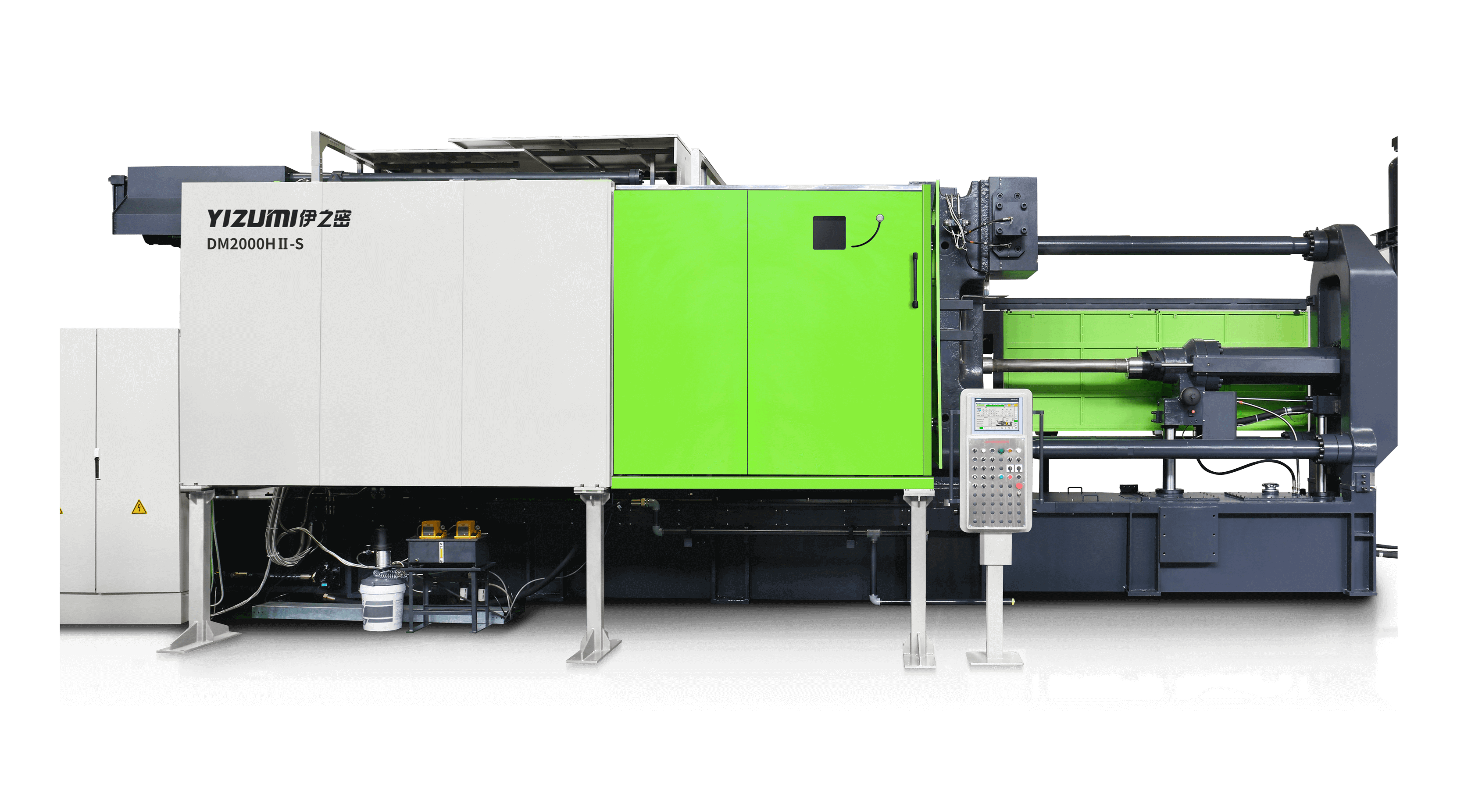

Cold Chamber Die Casting Machine

Cold chamber die casting machines are suitable for metals with higher melting points, such as aluminum and copper alloys. Unlike hot chamber machines, the molten metal is not in direct contact with the injection mechanism. Instead, it is poured into a separate injection cylinder before being forced into the die.

YIZUMI Cold Chamber Die Casting Machine

Operating Principle of Cold Chamber Die Casting

- Molten metal is ladled into the injection cylinder.

- A hydraulic plunger forces the molten metal into the die cavity under high pressure.

- The metal solidifies in the mold, producing a high-quality part.

- The die opens, and the finished part is ejected.

Cold chamber machines are slower than hot chamber systems due to the separate ladling process, but they excel in handling large and high-temperature metals safely.

Advantages of Cold Chamber Machines

High-temperature compatibility: Suitable for aluminum and copper alloys with high melting points.

Large part production: Capable of producing heavy-duty components for automotive and industrial machinery.

Precision control: Injection speed, pressure, and mold temperature can be precisely managed.

Reduced defects: Proper control minimizes porosity and improves mechanical strength.

Typical Applications

Cold chamber machines are widely used in industries that require strength, durability, and dimensional stability. Typical applications include:

Automotive: engine blocks, transmission housings, suspension components

Aerospace: structural components requiring high mechanical strength

Industrial machinery: pump housings, gearboxes, and other large parts

Suitable Materials

- Aluminum alloys

- Copper alloys

- Magnesium alloys (specialized Mg-Thixomolding equipment)

Cold chamber machines are preferred for parts that must withstand high stress, heat, or mechanical load, offering long-term reliability and performance.

Magnesium Thixomolding Machine

Other Types of Die Casting Machines

While hot and cold chamber machines dominate the industry, there are other die casting methods worth noting.

Squeeze Casting Machines

Squeeze casting combines die casting with forging techniques. Molten metal is poured into an open die and pressed under high pressure, reducing porosity and increasing part strength. Applications include structural automotive parts and high-performance aerospace components.

Low-Pressure Die Casting Machines

Low-pressure die casting uses a sealed furnace to fill molds from the bottom up with moderate pressure. This reduces turbulence and minimizes gas entrapment, producing parts with excellent surface finish and low porosity. Commonly used for automotive and aerospace structural components.

High-Pressure Die Casting Machines

High-pressure die casting machines inject molten metal at very high pressure, ideal for high-volume production of thin-walled parts. This method is widely used for consumer electronics housings, automotive body parts, and other precision components.

Choosing the Right Die Casting Machine

Selecting the right die casting machine depends on several factors:

Material Compatibility: Match your die casting machine with your chosen alloy.

Part Size and Complexity: Large, heavy parts typically require cold chamber machines; small, detailed parts suit hot chamber machines.

Production Volume: Hot chamber machines excel in high-volume production; cold chamber machines are better for medium-to-large production runs.

Surface Finish and Tolerance: Tight-tolerance parts require precise control of injection pressure and mold temperature.

Operational Costs: Consider energy consumption, maintenance, and labor requirements in your decision.

Conclusion

Hot and cold chamber die casting machines form the core of precision metal manufacturing. Hot chamber machines excel in fast, high-volume production of small parts with low-melting metals, while cold chamber machines handle larger, high-strength components made from aluminum or copper alloys. Secondary methods such as squeeze, low-pressure, and high-pressure die casting offer specialized solutions for strength, surface finish, or production scale.

For businesses seeking reliable, high-performance die casting machines, YIZUMI provides a comprehensive range of hot and cold chamber systems, including fully automated solutions designed for industrial efficiency and consistent quality. Selecting the right machine ensures your production meets quality standards, reduces waste, and improves overall operational efficiency.