PET Injection Molding Machines for Bottles, Containers & Packaging Solutions

Abstract:

For manufacturers producing PET bottles, cosmetic containers, or storage products, choosing the right injection molding machine is critical to achieving efficiency, quality, and cost-effectiveness. YIZUMI SPET Series PET injection molding machines offer a professional solution tailored to the needs of modern PET production.

PET (Polyethylene Terephthalate) has become the material of choice for a wide range of packaging applications due to its clarity, strength, and recyclability. From beverage bottles to cosmetic containers, PET products dominate the market because they combine durability with cost-effectiveness. Central to producing these high-quality PET products are specialized PET injection molding machines, designed to handle the unique properties of PET and deliver precise, efficient manufacturing.

For businesses and commercial projects looking to scale production or improve product quality, investing in advanced PET injection molding machinery is essential. Machines tailored for PET products offer improved plasticizing efficiency, precise control of molding parameters, and energy-saving features that directly impact profitability and sustainability.

Why PET Injection Molding Machines Matter?

PET injection molding machines differ from general-purpose injection molding machines in several key ways:

High-Temperature Plasticizing: PET requires precise temperature control to avoid degradation. PET injection molding machines are engineered with advanced heating and screw systems to maintain consistent melt quality.

Clamping Force Optimization: PET products, especially bottle preforms, demand a uniform clamping force to ensure mold accuracy and prevent flash or defects.

Energy Efficiency: Modern PET machines often feature electric or hybrid plasticizing systems that reduce energy consumption while maintaining high output.

Flexible Injection Units: Machines can adapt to varying product sizes and molds, offering versatility for multiple product lines.

These advantages make PET injection molding machines ideal for manufacturers seeking high efficiency, reduced waste, and consistent product quality.

PET Injection Molding Machine Applications

Applications of PET Injection Molding Machines

The scope of PET applications is extensive. Businesses commonly use PET injection molding machines to produce:

Bottle Preforms: PET preforms are the foundation of beverage bottles. Precision molding ensures uniform wall thickness, preventing bottle deformation during blow molding.

Cosmetic Containers: Cream jars, lotion bottles, and other cosmetic packaging require clarity and precise dimensions, which PET injection machines can consistently deliver.

Food Storage Products: PET’s chemical resistance and durability make it ideal for storage containers, jars, and other household items.

Industrial Packaging: PET containers for chemicals or pharmaceuticals benefit from the strength and barrier properties offered by high-quality PET molding.

By investing in specialized PET machinery, manufacturers gain a competitive edge, ensuring their products meet both regulatory and consumer standards.

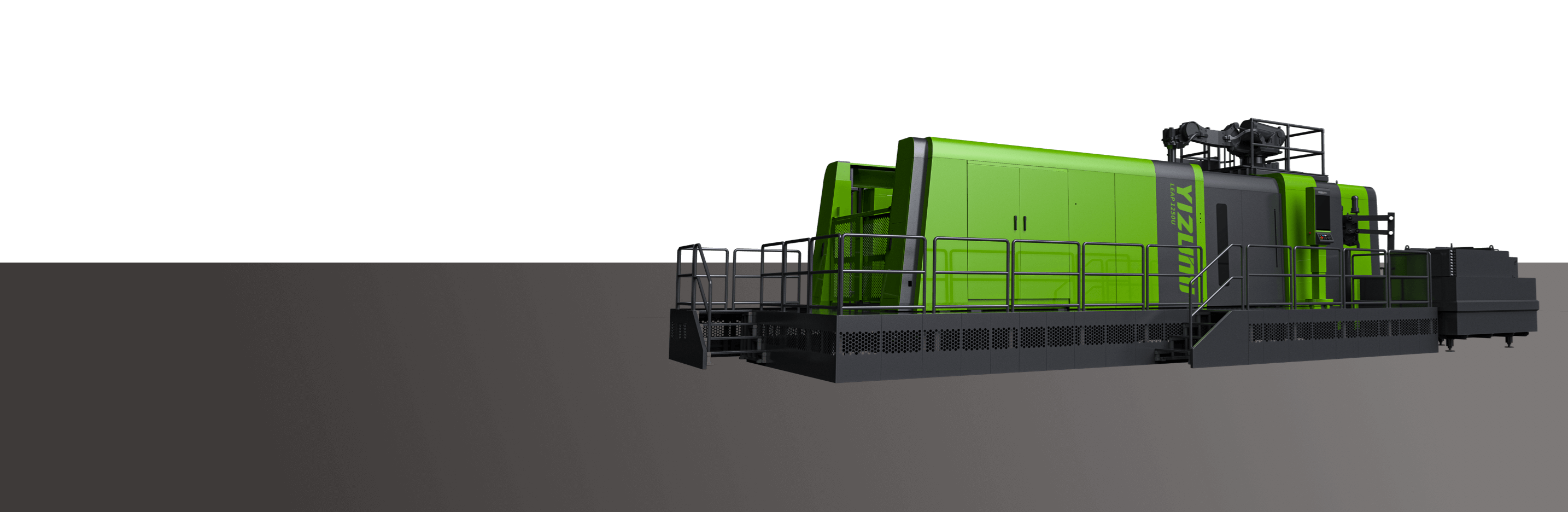

YIZUMI PET Injection Molding Machines

The YIZUMI SPET Series Injection Molding Machines are engineered for high-efficiency production of PET bottle preforms, cosmetic containers, and daily storage products. Designed to meet the demands of modern PET manufacturers, these machines combine precision, reliability, and energy efficiency to deliver consistent, high-quality outputs. Enhanced screw speed improves plasticizing capacity by 5–10%, while the standard electric plasticizing system reduces energy consumption by 10–30%, optimizing operational costs.

The SPET Series features a new-generation clamping unit with strong central support for the movable platen, minimizing deformation and ensuring even distribution of clamping force. This precision reduces mold cavity stress, enhances product quality, and contributes to energy savings. Highly rigid fixed and tail platen structures further reduce deformation, improving overall machine stability.

The injection system incorporates dual linear guides with self-lubrication, keeping operations clean and maintenance intervals extended, while the advanced hydraulic circuit ensures lower pressure loss and precise mold-open positioning. An upgraded, expandable control system provides real-time monitoring, precise 15-stage linear speed control, and multiple communication interfaces to support diverse production requirements. Optional energy consumption management allows users to monitor total, cycle, and instantaneous power usage, helping manufacturers optimize energy efficiency and production costs.

The SPET Series PET injection molding machine is a professional solution for businesses seeking reliability, performance, and energy savings in PET product manufacturing.

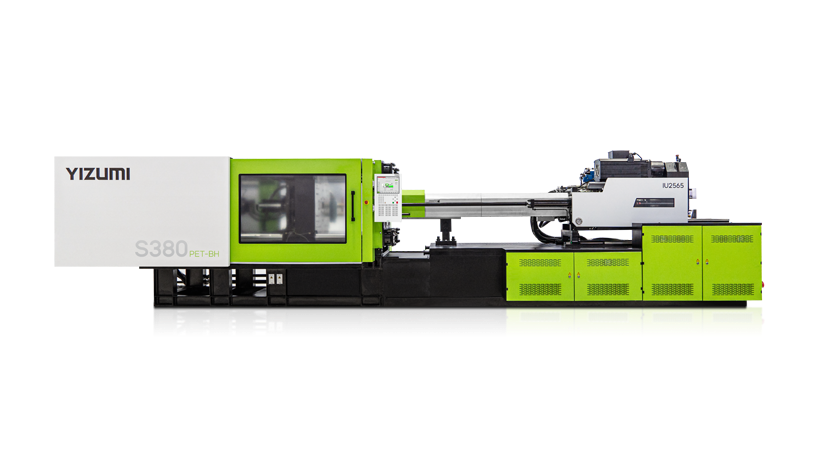

Injection Molding Machine For PET Products

Key Features Driving Productivity

Several features distinguish YIZUMI PET machines in terms of operational efficiency and business value:

Energy-Saving Design: Electric plasticizing systems and optimized hydraulic circuits reduce electricity consumption without compromising output.

Precision Clamping: Strong central support in the movable platen minimizes mold deformation, ensuring consistent product dimensions.

Flexible Injection Configurations: Machines can adapt to a wide range of PET product sizes, from small cosmetic jars to large beverage preforms.

Low Maintenance Requirements: Self-lubricating guides and extended oil change intervals lower maintenance costs and downtime.

Advanced Control Systems: Real-time monitoring, RS232/485 communication, and temperature compensation improve safety and process accuracy.

Energy Consumption Management (Optional): Track total, cycle, and instantaneous power use to make informed decisions about production efficiency.

These features translate into faster production cycles, higher product quality, and reduced operating costs—critical considerations for commercial buyers.

Selecting the Right PET Injection Molding Machine

When evaluating PET injection molding machines, businesses should consider:

Clamping Force Range: Ensure the machine can handle the size and complexity of your molds. The SPET Series ranges from 1,600 to 10,000 kN.

Injection Capacity: Look for machines capable of achieving the required shot size and plasticizing speed for your product line.

Energy Efficiency: Energy-saving systems reduce costs and support sustainability initiatives.

Maintenance and Longevity: Machines with long oil change intervals, self-lubrication, and robust construction minimize downtime.

Control Systems: Advanced, expandable control systems improve production monitoring, safety, and integration with existing factory automation.

By carefully matching machine specifications to production requirements, manufacturers can maximize return on investment and operational efficiency.

PET Preform Mold For Injection Molding

Business Benefits of YIZUMI PET Machines

Investing in YIZUMI PET injection molding machines offers several tangible benefits for manufacturers:

Reduced Production Costs: Energy-efficient systems and optimized injection cycles lower electricity and material waste.

Consistent Product Quality: Precision clamping and advanced injection control minimize defects and improve mold accuracy.

Operational Flexibility: Flexible injection units and adaptable machine configurations allow businesses to diversify their product portfolio.

Sustainability: Lower energy consumption and clean hydraulic systems contribute to environmentally responsible production.

Scalability: High-capacity machines support business growth, from small batch production to large-scale manufacturing.

These advantages make YIZUMI PET machines a strategic investment for businesses looking to expand or modernize their PET product manufacturing operations.

Conclusion

For manufacturers producing PET bottles, cosmetic containers, or storage products, choosing the right injection molding machine is critical to achieving efficiency, quality, and cost-effectiveness. YIZUMI SPET Series PET injection molding machines offer a professional solution tailored to the needs of modern PET production.

With advanced clamping units, energy-efficient plasticizing systems, precise control capabilities, and optional energy consumption monitoring, YIZUMI PET injection molding solutions deliver consistent, high-quality results while optimizing operational costs. Please feel free to contact us for further information!