Machine Video

Home

Products & Solutions

Die Casting and Metal Forming

Thixomolding

Products

Thixomolding machine

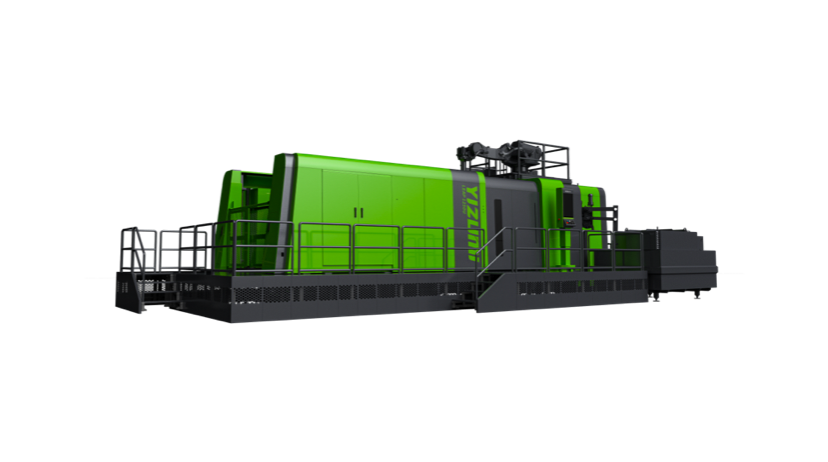

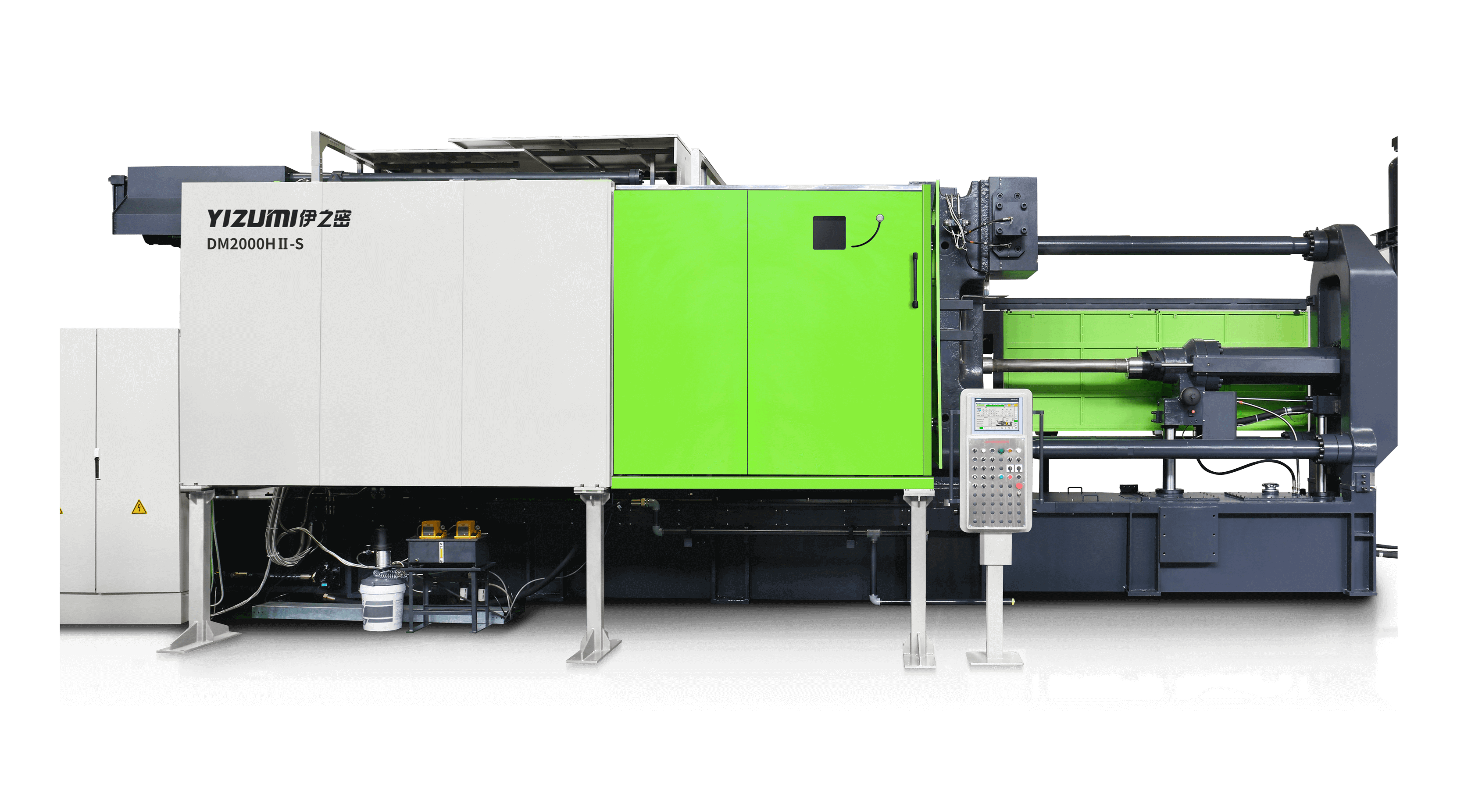

MGII · Plus Series Thixomolding Machine

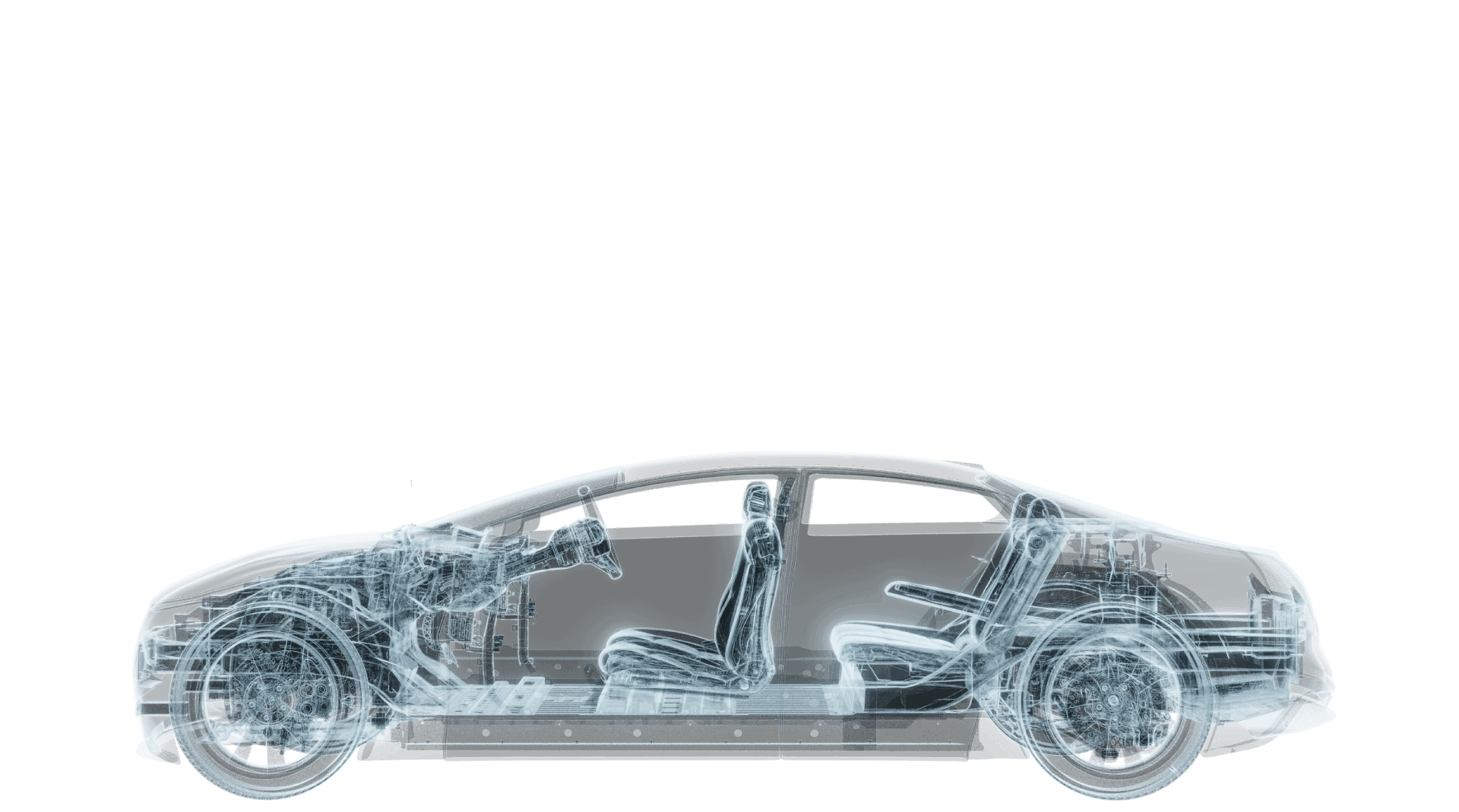

Specializing in the efficient mass production of large, thin-wall, and thick-wall magnesium alloy parts, we offer one-stop lightweighting solutions for the automotive, 3C electronics, sports equipment and tools, low-altitude economy, and humanoid robotics. Our goal is to drive large-scale application and industrial upgrading of magnesium alloy.

Increase max. effective shot weight

Lower the cost per shot

Enhance injection pressure and clamping force

Lower the overall machine energy consumption

Machine Video

Turbo High-Speed Injection System

The large-diameter high-speed servo valve controls the oil inlet valve opening with a 12 ms rapid response time. The injection piston acceleration can reach up to 20G, paired with an ultra-large capacity accumulator, delivering powerful and efficient injection performance.

Eco Energy-Efficient Melting Technology

Utilizing European-standard special steel (resistant up to 630?°C) combined with infrared heating technology and high-torque servo drive, this technology achieves highly efficient and energy-saving melting with an extended service life.

Multi-Hot Runner Technology

Enables precise and multiple melt deliveries, uniform temperature and pressure distribution within the mold cavities, reducing casting waste by 30% and eliminating part deformation. This technology is patented as a multi-gating system (Patent No.: 2025050100300960).

Intelligent Control Technology

Equipped with a high-performance controller, the system achieves ±0.1?mm precision control and real-time process monitoring. Its modular design and intelligent connectivity enable a fully digital solution for the entire YIZUMI Thixomolding process.

One-Stop Rapid Implementation Service for Thixomolding Product Development

- YIZUMI provides a one-stop rapid implementation service for magnesium alloy product development. The service covers the entire process—from Thixomolding sample preparation, material property testing and data validation, product modeling and 3D optimization, mechanical and process simulation, mold design and manufacturing, to trial casting and sample parts delivery.

- By offering an integrated solution that combines equipment with material, design, and manufacturing expertise, YIZUMI helps reduce development risks and ensures the rapid and high-quality production of magnesium alloy structural components.

- By offering an integrated solution that combines equipment with material, design, and manufacturing expertise, YIZUMI helps reduce development risks and ensures the rapid and high-quality production of magnesium alloy structural components.

Yi+ “Thixomolding On-Site Steward Service”

- Full Lifecycle Safeguard for Thixomolding Mass Production

- YIZUMI’s original “Thixomolding On-Site Steward Service” provides comprehensive, hands-on support throughout the entire process. Acting as a technical steward, it accompanies the project from start to finish, ensuring customers achieve “zero-barrier” rapid mass production.

- YIZUMI’s original “Thixomolding On-Site Steward Service” provides comprehensive, hands-on support throughout the entire process. Acting as a technical steward, it accompanies the project from start to finish, ensuring customers achieve “zero-barrier” rapid mass production.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.