Key Applications of Two-Platen Injection Molding Machines in the Automotive Industry

Abstract:

Among various injection molding machines, two-platen injection molding machines have gained prominence for their ability to handle large-scale and multi-component automotive parts efficiently.

The automotive industry demands precision, efficiency, and flexibility in manufacturing, especially for high-volume production of complex components. Injection molding has become an essential technology in automotive manufacturing, offering fast, accurate, and repeatable production of plastic parts. Among various injection molding machines, two-platen injection molding machines have gained prominence for their ability to handle large-scale and multi-component automotive parts efficiently.

Why Two-Platen Injection Molding Machines Are Ideal for Automotive Manufacturing

Two-platen injection molding machines are distinguished by their dual-platen clamping system, which offers several advantages over traditional single-platen machines. The dual-platen structure provides higher rigidity, better stability, and larger mold space. These features are particularly valuable in automotive applications where precision and durability are critical.

Some key benefits of two-platen injection molding machines include:

Enhanced Clamping Capacity: Two-platen machines can support high clamping forces, making them suitable for producing large or complex automotive parts such as bumpers, dashboards, and structural panels.

Improved Stability: The dual-platen design ensures uniform clamping pressure across the mold, reducing warping and ensuring dimensional accuracy.

Flexibility in Multi-component Molding: Many automotive components require multi-material or multi-color molding. Two-platen machines can integrate multiple injection units, allowing complex parts to be produced in a single step.

Cost Efficiency: By combining multiple processes into one, these machines reduce production time, energy consumption, and labor costs.

Two-Platen Injection Molding Machine For Car Lights

Automotive Components Produced with Two-Platen Injection Molding Machines

The versatility of two-platen injection molding machines allows them to be applied across a wide range of automotive components:

1. Exterior Automotive Parts

Automotive exteriors, such as bumpers, fenders, and side panels, require both precision and durability. Two-platen injection molding machines can handle large molds while providing consistent clamping force, resulting in high-quality finished surfaces. Multi-component machines also allow the integration of color or material variations, producing parts with soft-touch areas or different textures in one cycle.

2. Interior Components

Interior components, such as dashboards, door panels, and center consoles, often combine multiple materials, including soft-touch plastics, rigid substrates, and even decorative finishes. Multi-component two-platen injection molding machines can integrate multiple injection units and use horizontal turntable systems to produce these complex parts efficiently. This capability reduces assembly steps and improves product consistency.

3. Functional Automotive Parts

Automotive functional parts, such as air vents, battery covers, and structural brackets, require high precision and mechanical strength. Two-platen injection molding machines provide high repeatability and precise injection control, ensuring the consistent weight and mechanical properties of each part. The ability to handle large molds with high clamping forces makes these machines suitable for both small and large functional components.

4. Multi-color and Multi-material Applications

Modern automotive design often integrates aesthetic and functional multi-material components. Two-platen injection molding machines excel in multi-component molding, enabling the production of parts with overmolded sections, dual colors, or combinations of rigid and soft materials. This capability reduces post-processing, assembly costs, and lead times while enhancing product aesthetics and performance.

Two-Platen Injection Molding Machine For Auto Parts

Advantages of Two-Platen Injection Molding Machines in Automotive Production

Automotive manufacturers face increasing pressure to optimize production efficiency while maintaining strict quality standards. Two-platen injection molding machines contribute to these objectives through:

High Precision and Repeatability: Advanced injection systems and digital closed-loop positioning control ensure consistent part quality.

Reduced Cycle Time: Large mold openings and integrated clamping systems allow faster mold changes and shorter production cycles.

Energy Efficiency: Optimized hydraulic and servo systems minimize energy consumption without compromising performance.

Versatility: Two-platen injection molding machines accommodate a wide range of molds, materials, and production techniques, making them adaptable to changing automotive design requirements.

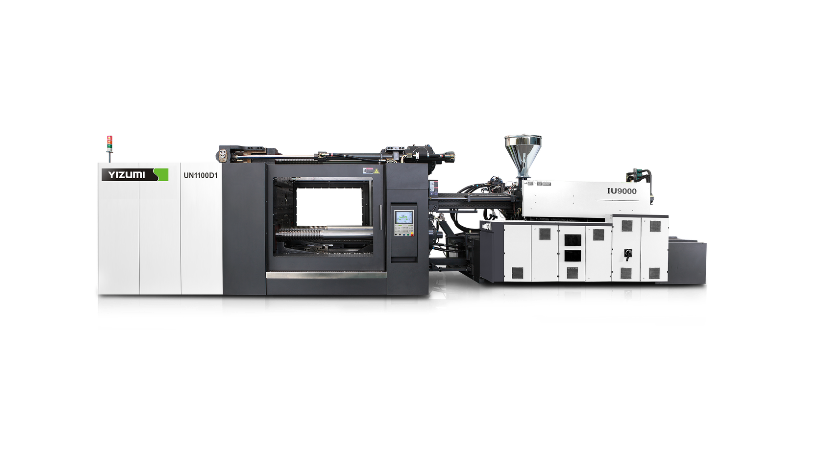

YIZUMI D1M Series Two-platen Injection Molding Machine

The YIZUMI D1M Series Two-platen multi-component injection molding machine represents the leading edge of multi-component molding technology for the automotive sector. Designed for high-end applications, the D1M series simplifies complex production processes by integrating multiple functions into a single step.

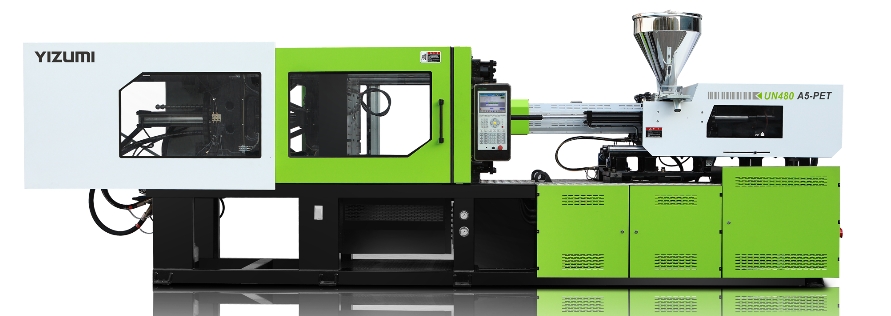

YIZUMI Two-Platen Injection Molding Machine

Technical Features Enhancing Automotive Manufacturing

The D1M series two-platen injection molding machines integrate advanced technologies to maximize efficiency, precision, and safety in automotive manufacturing:

Horizontal Turntable Systems: Ideal for long or large multi-color automotive parts, the horizontal turntable reduces clamping force requirements while allowing seamless integration with multiple injection units (W type, L type, V type), supporting cost-effective multi-component production.

Servo-driven Turntables: Equipped with a high-precision servo motor and advanced digital closed-loop positioning control, the turntable ensures smooth, accurate, and repeatable rotation (±0.005°), critical for precise multi-component parts manufacturing.

Automatic Flow-Distribution Systems: German-engineered centralized management of oil, water, and gas delivers consistent performance, reduces wear, and enables multi-angle rotation (0°, 90°, 120°, 180°, 240°, 360°) without pipeline tangling, providing flexibility for various automotive applications.

High Injection Repeatability: Advanced European single-cylinder technology combined with high-mixing, anti-stick screws, proportional valve-controlled back pressure, and PID temperature regulation ensures precise, stable injection performance and consistent product quality (repeatability up to 3‰).

User-friendly Interface: The Austrian KEBA controller provides reliable, safe, and efficient operation, compatible with a wide range of multi-component molding solutions.

Flexible Clamping Force: The D1M series offers clamping forces from 5,000 to 24,000 kN, accommodating both small and large automotive components.

Conclusion

Two-platen injection molding machines are transforming automotive manufacturing by offering high precision, multi-component capabilities, and efficient production for large and complex parts. From exterior panels to interior trim, functional components, and multi-material applications, these machines meet the demanding requirements of modern automotive production.

With solutions like the YIZUMI D1M Series, automotive manufacturers can achieve higher productivity, improved part quality, and reduced operational costs. By integrating advanced clamping, injection, and turntable technologies, YIZUMI continues to provide reliable, versatile, and innovative two-platen injection molding machines for the automotive industry.