Application Highlights

Innovative Product Design

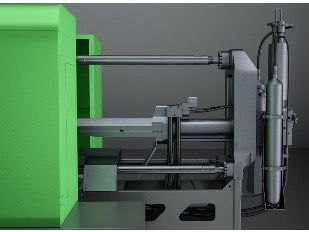

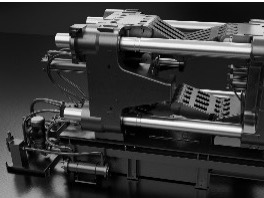

The integrated die-casting structural parts allow the rear floorboard of new energy vehicles to be made in one step. The projected area will be extremely large and the casting weight will reach 100 kg. It requires the use of 6000-9000 tonnage ultra-large die-casting machines, which creates both an opportunity and a challenge for the traditional die-casting industry.

Innovation Advantages

Unlike conventional die castings, the average wall thickness of structural parts is only about 3.5 mm. The development of heat treatment-free materials has made subsequent automotive component joining requirements possible.

Core Technology

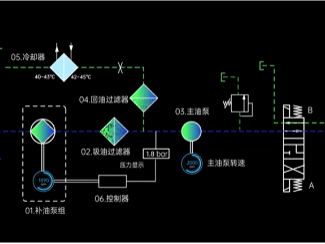

YIZUMI's powerful technical teams in China and Europe can provide customized die-casting units for customers. LEAP series super-large die-casting machines equipped with Yi-cast real-time controlled die-casting system developed by YIZUMI have ultra-high dynamic die-casting force, which ensures sufficient filling capacity and is an important quality assurance for super-large integrated die-castings.

Process Technology

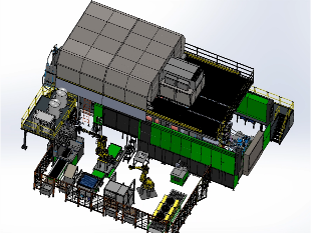

YIZUMI's integrated control technology enables effective control of major peripheral equipment in the die-casting cell and precise monitoring of up to 100 process parameters, allowing full quality assurance of each product.

Service Process

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

- Product performance

- Product quality

- Ease of use

- Safety requirements

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

- Professional installation and debugging

- On-site operation training

- Molding process training

- YFO services

- Preventive maintenance

- Device upgrade

![[old]LEAP Series Die Casting Machine](/uploads/2022-12-14/71015ea3-f53f-43c6-9176-88fc631e01a11670947886135.png)