Machine Video

Home

Products & Solutions

Die Casting and Metal Forming

Die Casting

Products

Ultra Large Series

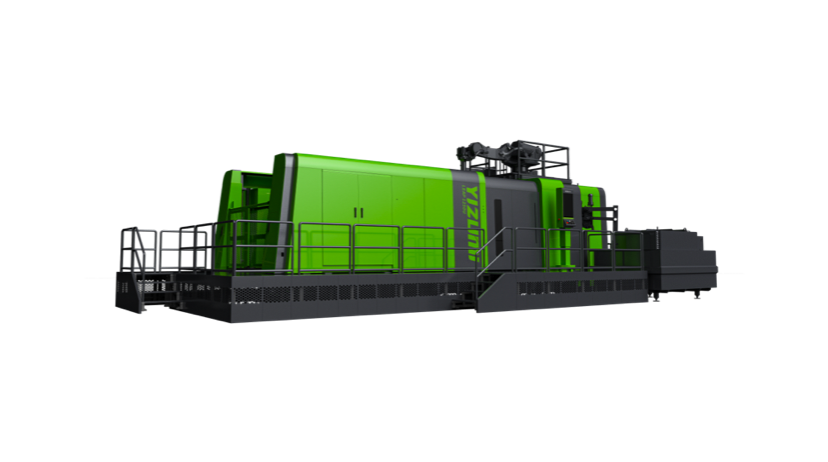

LEAP Series Ultra-large Die Casting Machine

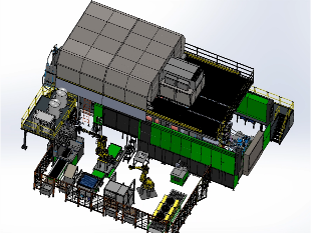

Integrating global engineering innovation with YIZUMI’s R&D excellence, the LEAP Series Ultra-large Die Casting Machine ensures supreme casting precision and reproducibility. Specializing in new energy vehicles, transportation facilities, aerospace, and other fields, we provide a more cost-effective ultra-large integrated die casting solution for customers. Available with die locking forces from 6000T to 9000T.

User-Friendly

Intuitive ORCA-HMI by YIZUMI.

Highly Efficient

10 % faster & highly repeatable.

Precise & Repeatable

Yi-Cast self-learning real-time control.

Energy-Saving

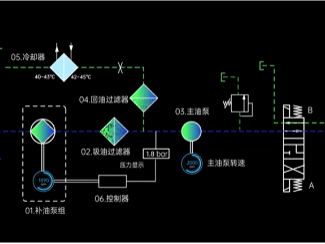

Up to 40 % with innovative hydraulic.

Machine Video

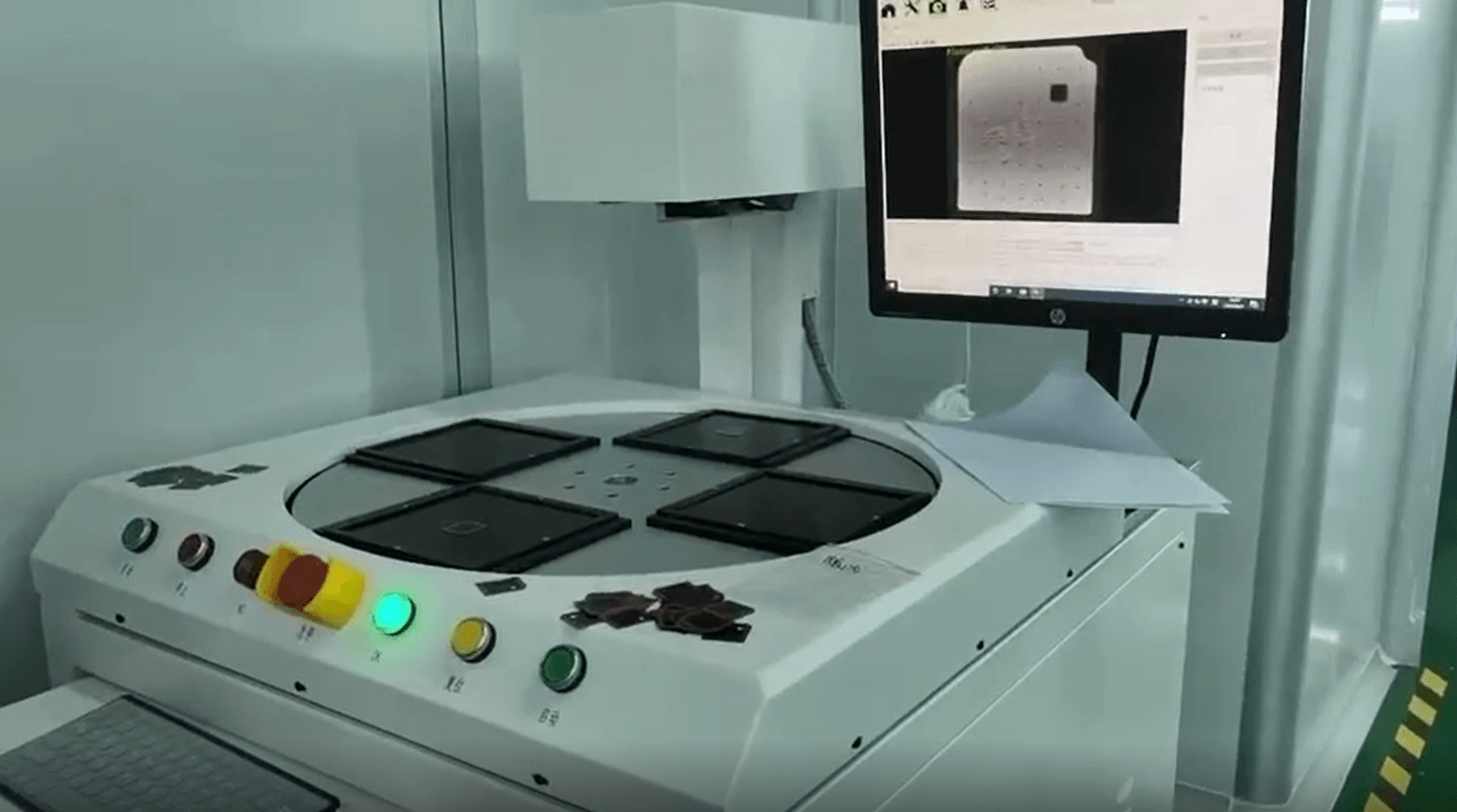

YIZUMI ORCA Control System

Fully Digital Control

With its easy-to-understand and intuitive graphical HMI, the ORCA control system provides maximum flexibility in managing the casting process.

Alarm and Trouble-shooting System

The ORCA control system has a well-documented alarm system built in to provide operational guidance and rapid troubleshooting to customers.

CastMaster Functions

The ORCA control system features a “built-in experts' system” which can guide customers with valuable technology information in the die-casting process.

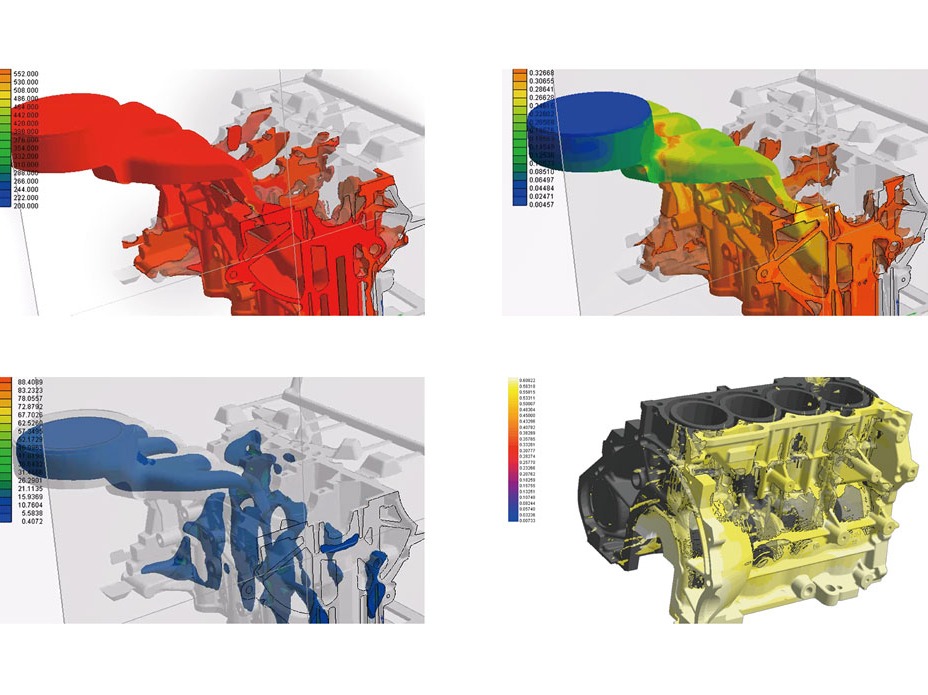

Yizumi Research Center for Die Casting and Metal Molding Mold

Mold Flow and Process Analysis

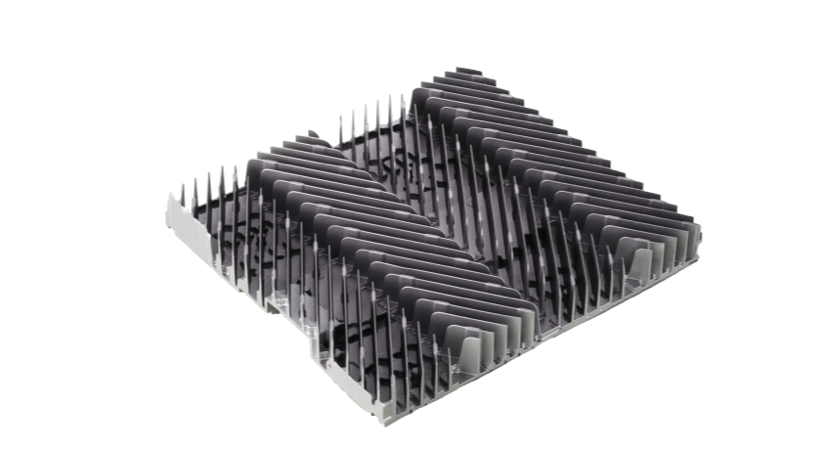

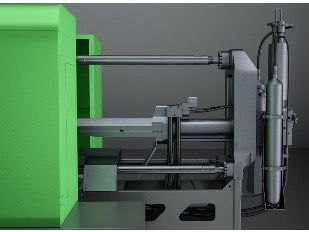

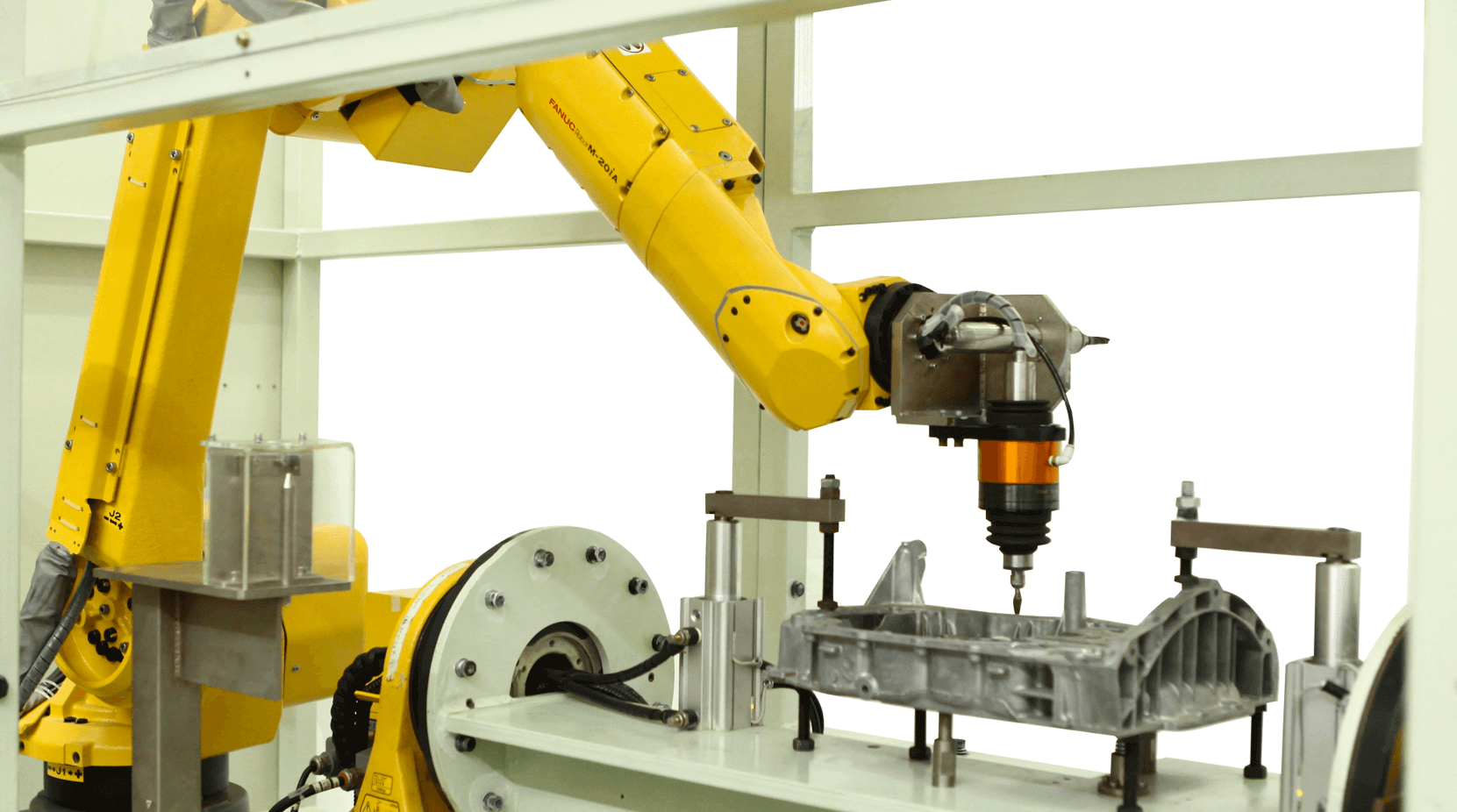

LEAP Injection Unit –Quality with Every Shot

- The YIZUMI real-time closed-loop control system detects any process deviation and immediately adjusts the injection process. This greatly enhances your process repeatability and your casting quality consistency;

- Breaking of the injection speed at the end of cavity filling reduces flash and increases productivity and die life.

- Breaking of the injection speed at the end of cavity filling reduces flash and increases productivity and die life.

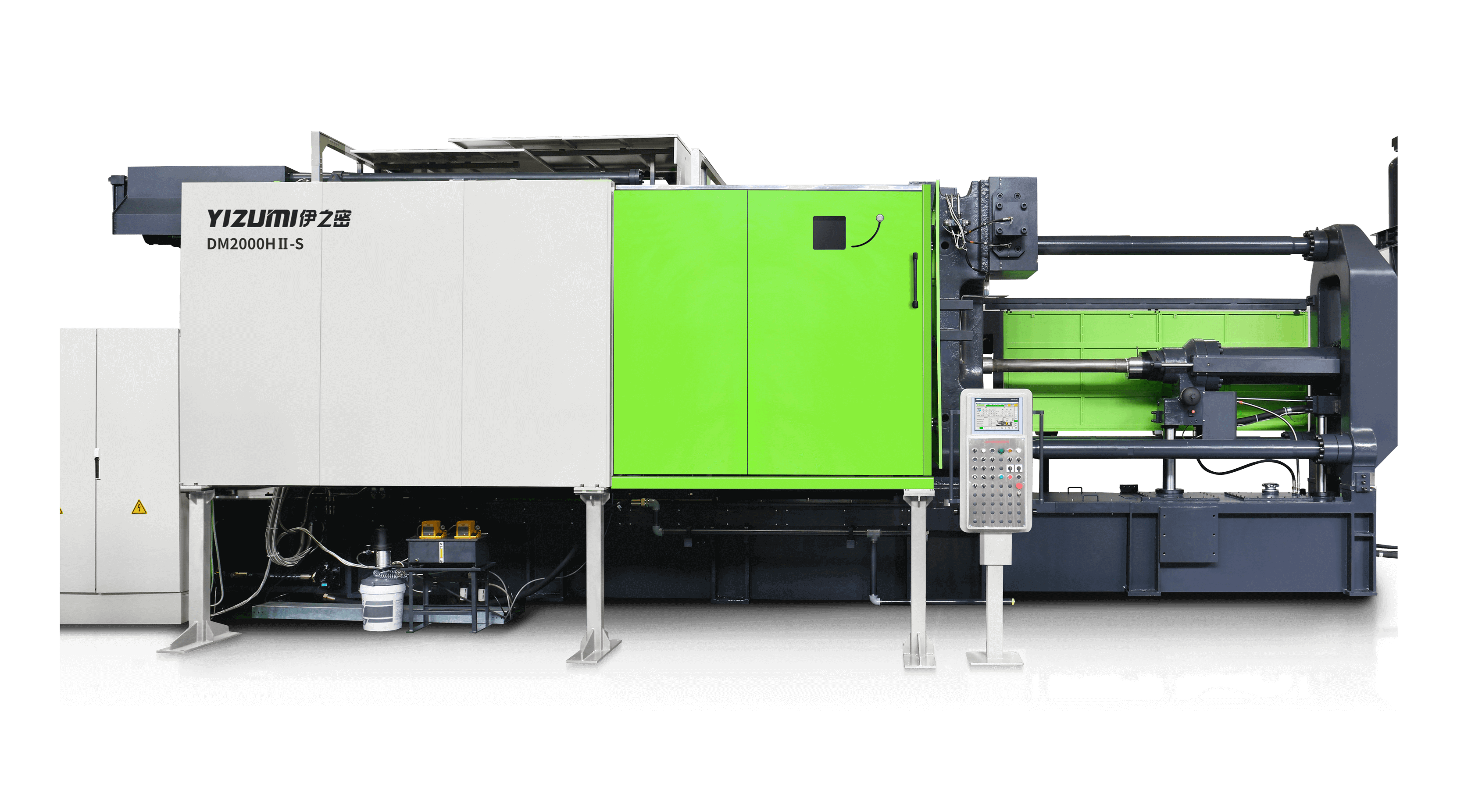

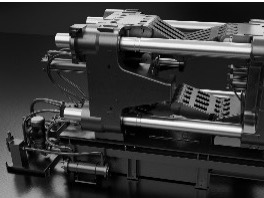

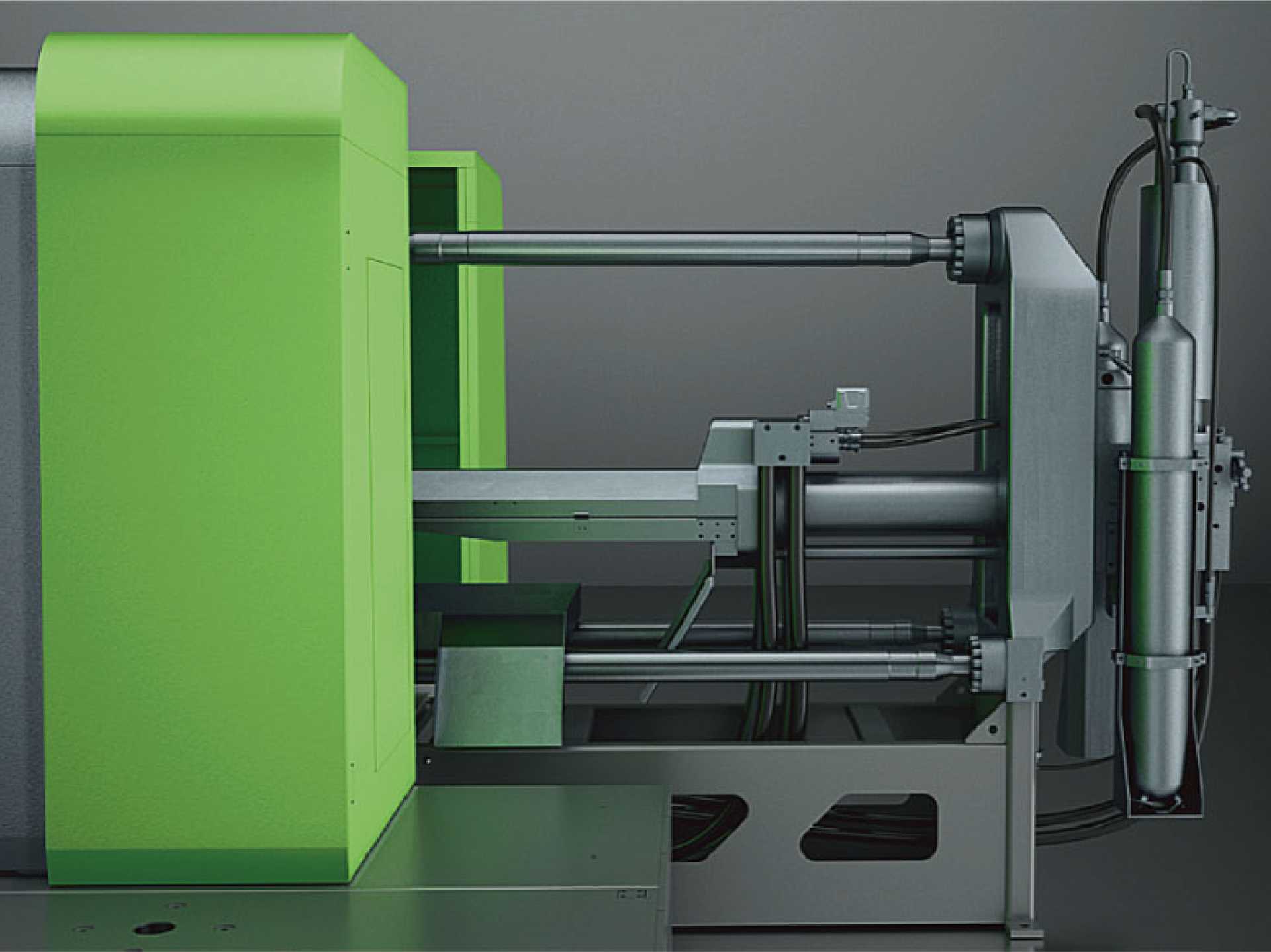

Enhanced YIZUMI Locking End

- A new fully re-engineered toggle system for extended service life and higher platen rigidity;

- 10% faster closing and opening times are achieved in combination with the innovative YIZUMI hydraulic drive system. The proven servo motors, a technology that has been in use for years at YIZUMI, reduce up to 40% energy consumption;

- Easy programming of speeds, automatic die-height & locking force, as well as precise die-position stops, add to the overall efficiency.

- 10% faster closing and opening times are achieved in combination with the innovative YIZUMI hydraulic drive system. The proven servo motors, a technology that has been in use for years at YIZUMI, reduce up to 40% energy consumption;

- Easy programming of speeds, automatic die-height & locking force, as well as precise die-position stops, add to the overall efficiency.

Performance Focused Machine Design

Our new design protects your personnel by keeping energy lines and moving parts away, while allowing open access to your operations and maintenance teams in a perfect balance between safety and efficiency.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.