Machine Introduction

Home

Products & Solutions

Die Casting and Metal Forming

Die Casting

Products

HII-S Series

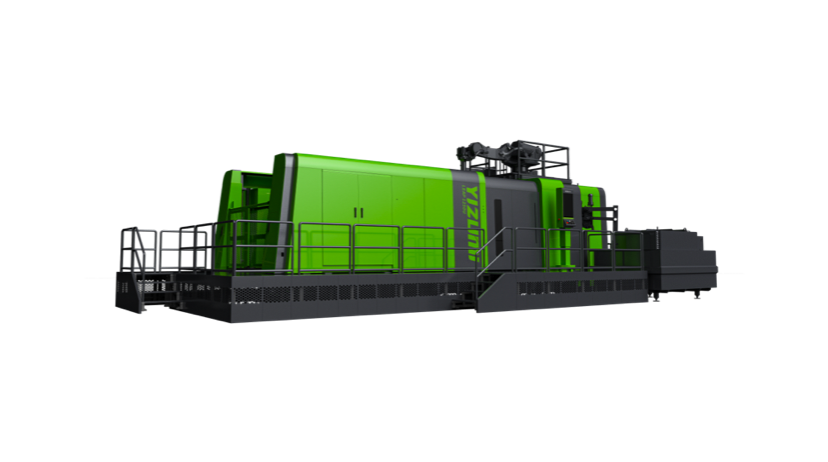

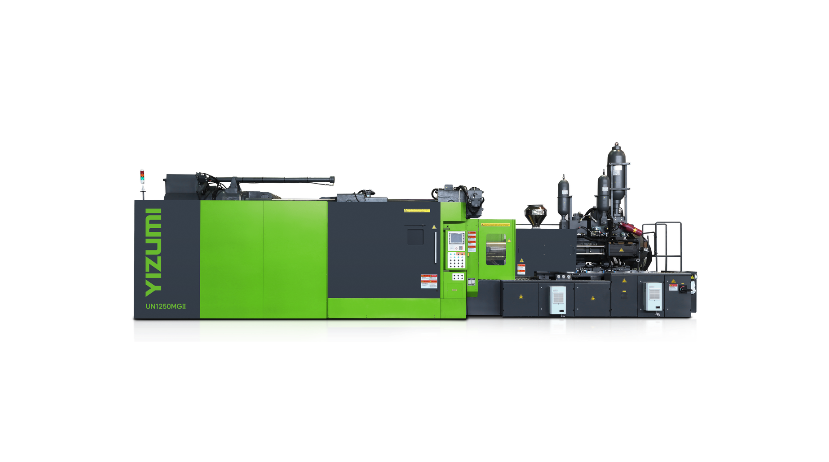

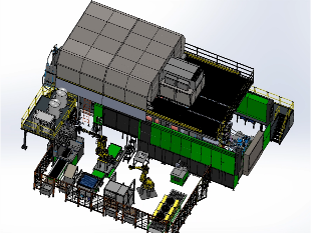

HII-S Series High-end Cold Chamber Die Casting Machine(1000-9000T)

Engineered for peak performance, this Cold Chamber Die Casting Machine HII-S Series merges YIZUMI’s expertise with human-centric innovation. Its intuitive HMI enhances operational efficiency, while advanced hydraulics shorten cycle times and cut energy use. Precision-cast components benefit from reduced pressure build-up, high-speed acceleration, and global-standard repeatability. Available with die locking forces from 1000T to 9000T.

Safe and Reliable

Precise and Stable

Efficient and Durable

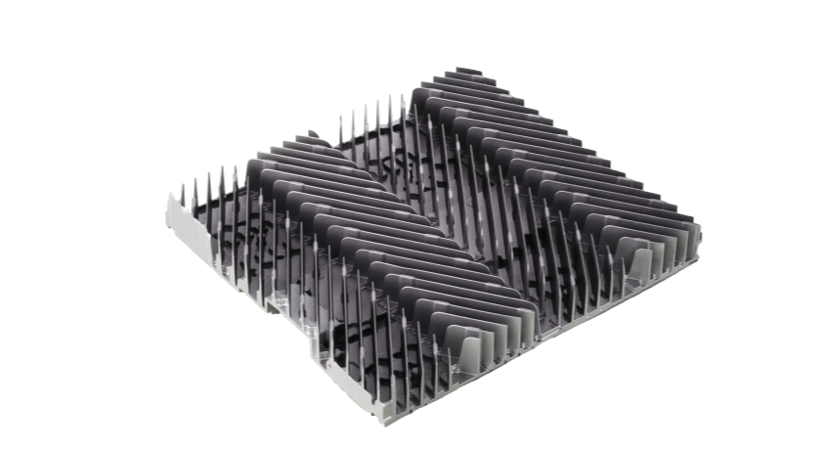

Wide Range of Application

Machine Introduction

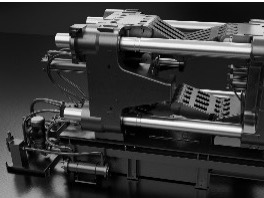

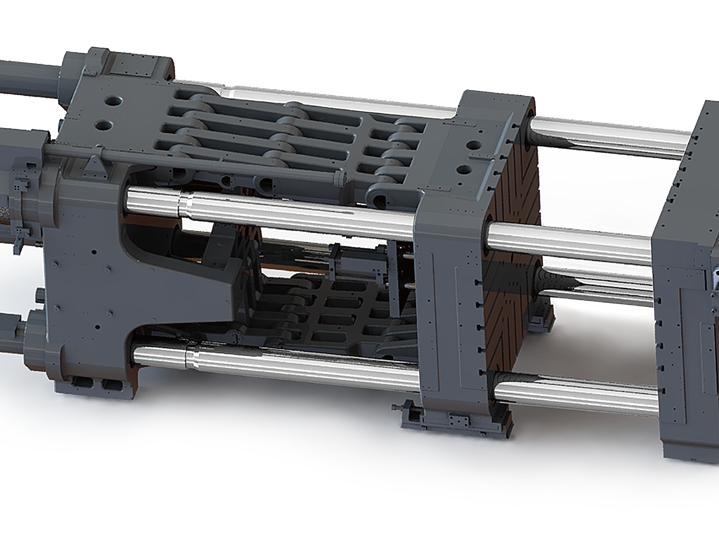

Clamping Unit

Re-Designed high rigidity platen

- Further increased platen rigidity protects the die casting tools during operation;

- A new design based on FEM analysis offers an even distribution of force by minimized platen bending.

- A new design based on FEM analysis offers an even distribution of force by minimized platen bending.

Auto die height adjustment

- Ensuring stable locking forces during volume production, the auto die height adjustment supports a stable operation.

- Automatic re-adjustment of the target locking force during production start-up offers further production efficiency.

- Automatic re-adjustment of the target locking force during production start-up offers further production efficiency.

Six tie-bar design

Locking ends of 2500T and higher are designed in our six-bar tie design, which ensures efficient and smooth die closing and open movements for the fastest machine cycle time.

Injection Unit

Pressure build-up time shortened by 30%

Further improved pressure build-up time by over 30%. The HII-S pressure build-up time offers great performance to any casting process.

Precision improved by 20%

The HII-S provides a high standard of precision to switch over to the cavity filling phase. The deviation between setting and actual value is a mere ≤5mm and a repeatability of ≤3mm satisfies the highest requirements.

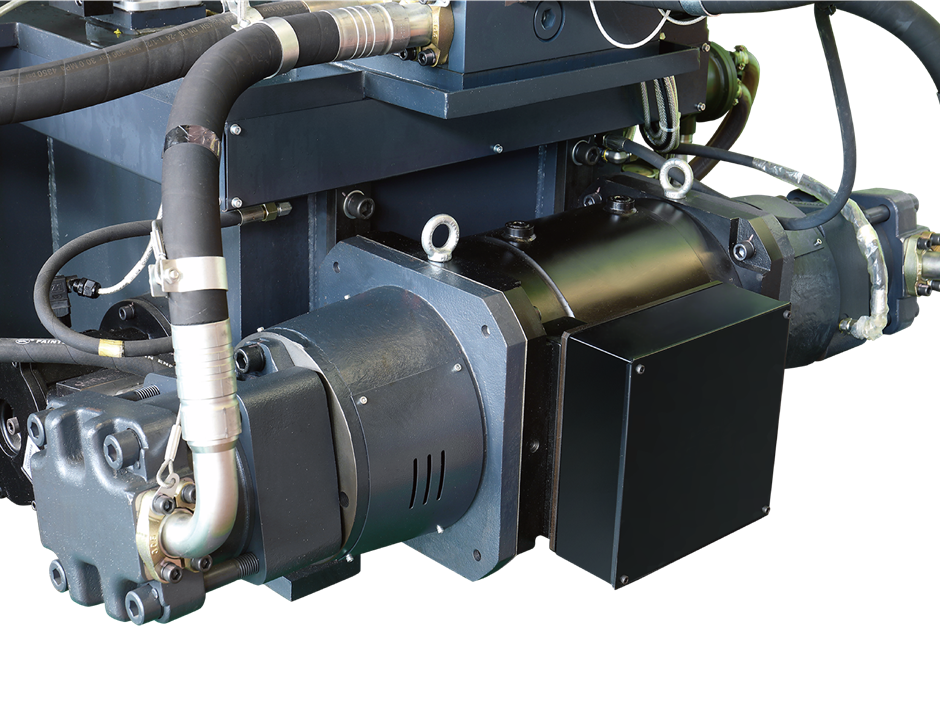

Fast and Precise Hydraulic Drive System

Additional personnel safety

- The third generation servo drive offers even Less noise emissions if compared to the previous design. System noise reduction of about 20%;

- High-pressure hydraulic hoses are equipped with steel hose-collars secured on wire ropes. This additional safety feature effectively protects personnel.

- High-pressure hydraulic hoses are equipped with steel hose-collars secured on wire ropes. This additional safety feature effectively protects personnel.

Optimized oil tank structure

An optimized interior structure of the oil tank improves heat dissipation and ensures effective management of oil quality and operating temperature. A design solution extends the service life of hydraulic components.

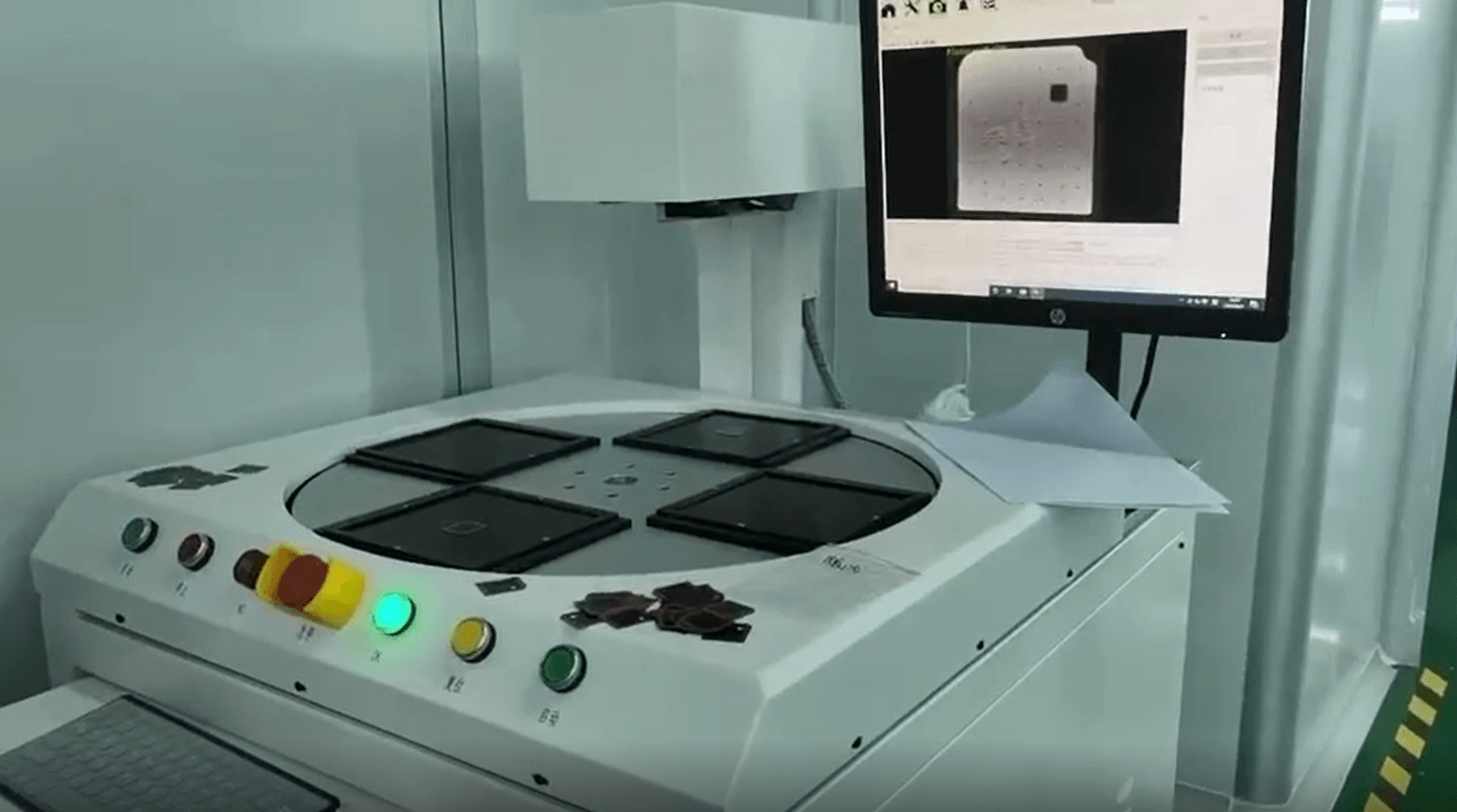

International Standard Electrical Control System

- Further optimized layout and structure of our HMI increases flexibility in managing machine functions via a large touchscreen;

- Intuitive and easy-to-understand maintenance functions, such as maintenance tips, comprehensive alarm messages as well and operation guidance, increase operational efficiency;

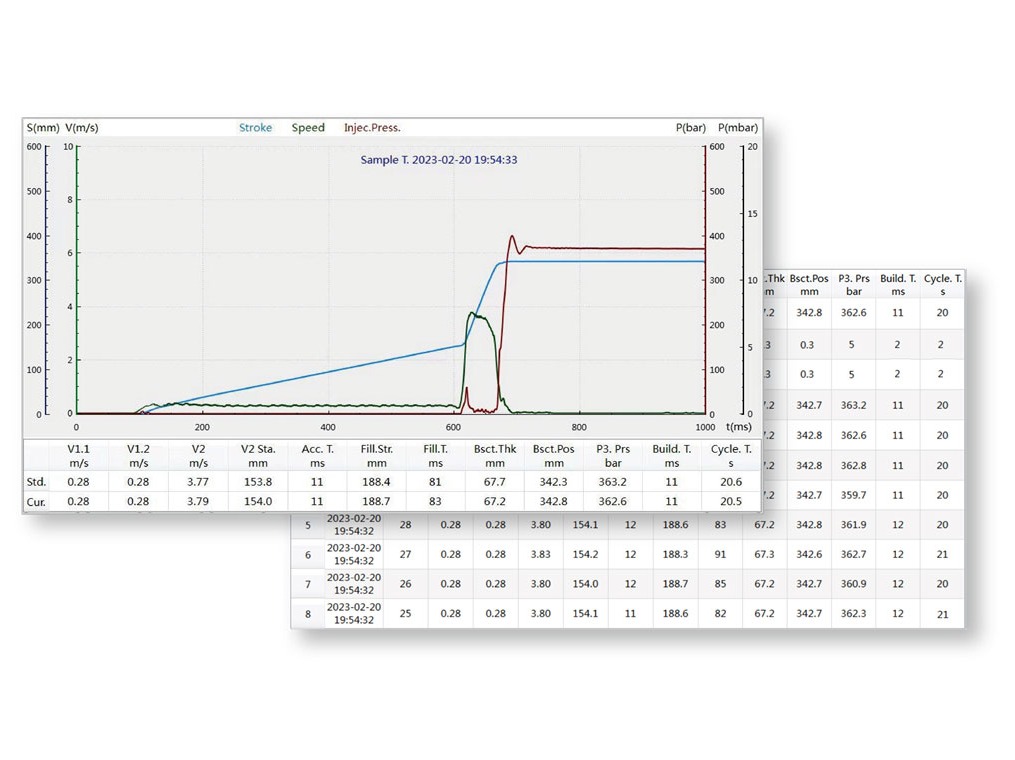

- The YIZUMI QC package offers precise recording and display of the casting injection curves as well as monitoring of key casting process parameters, including individual parameter tolerance settings. Casting Quality control made easy.

- Intuitive and easy-to-understand maintenance functions, such as maintenance tips, comprehensive alarm messages as well and operation guidance, increase operational efficiency;

- The YIZUMI QC package offers precise recording and display of the casting injection curves as well as monitoring of key casting process parameters, including individual parameter tolerance settings. Casting Quality control made easy.

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

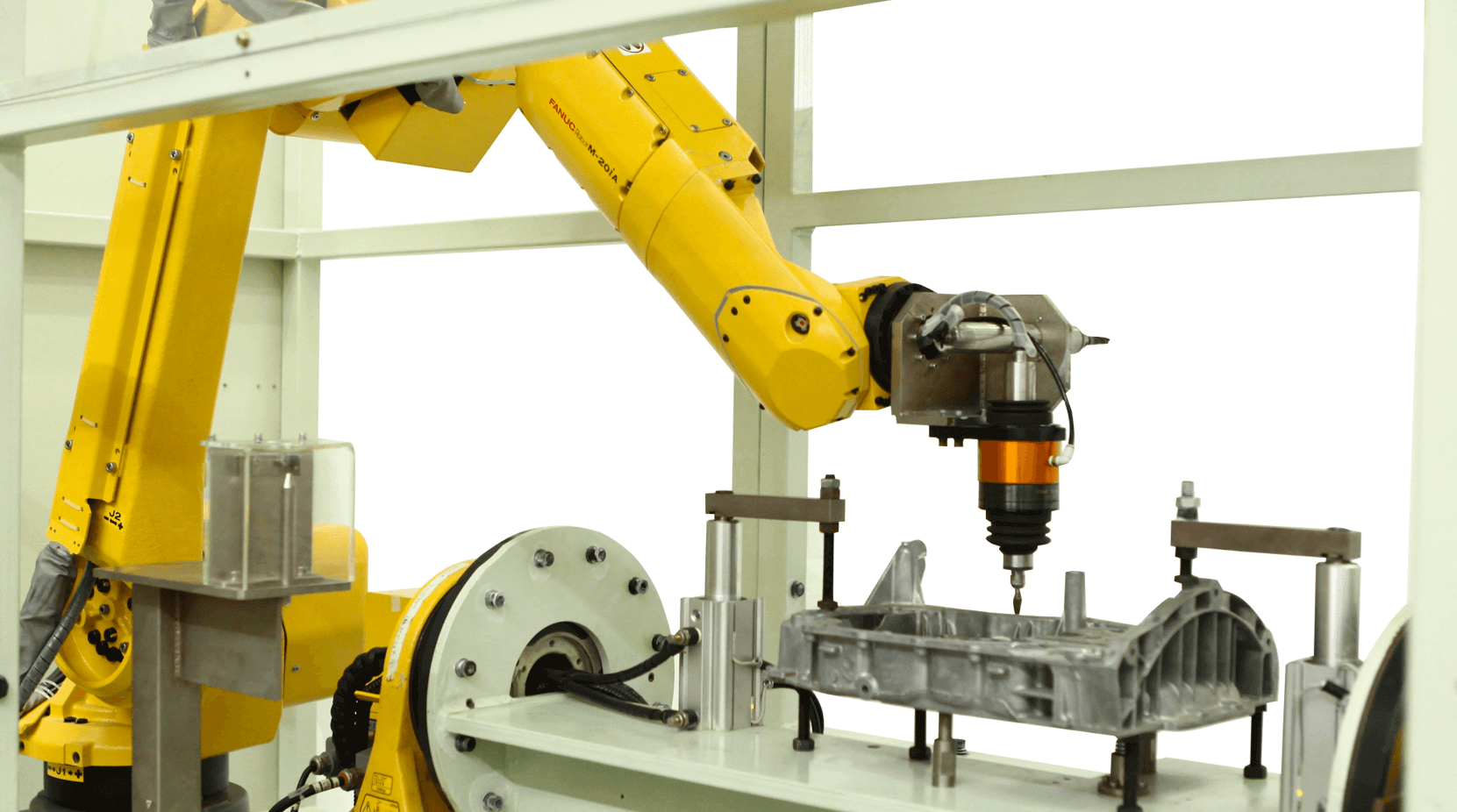

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.