Home

Products & Solutions

Die Casting and Metal Forming

Die Casting

Products

HII Series

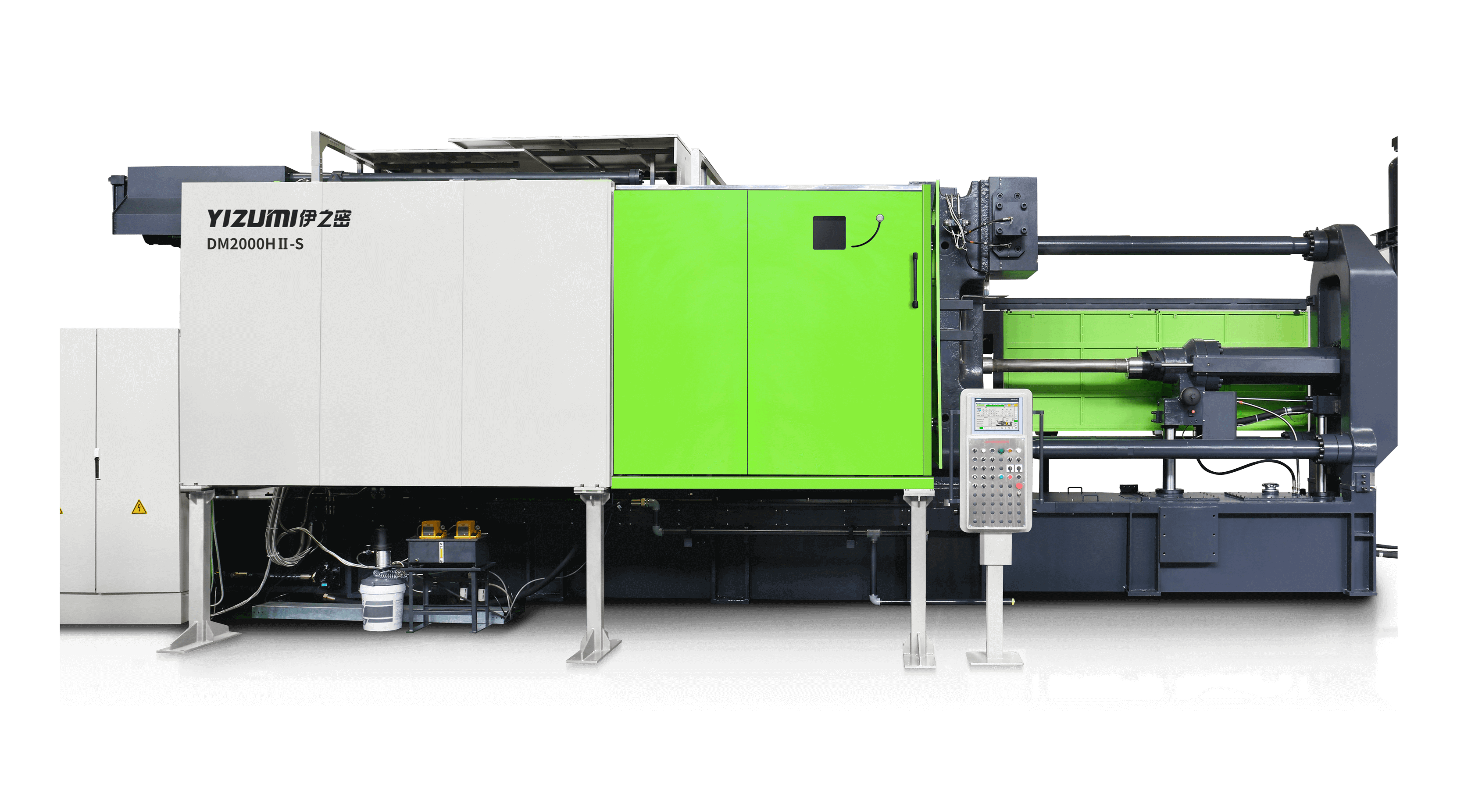

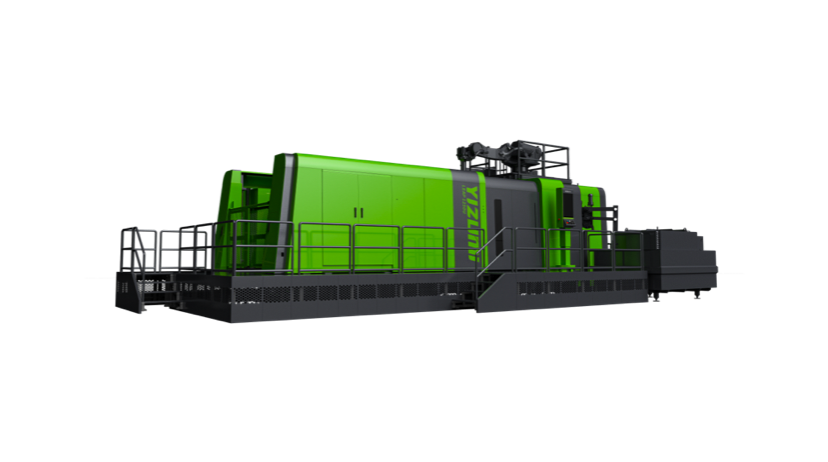

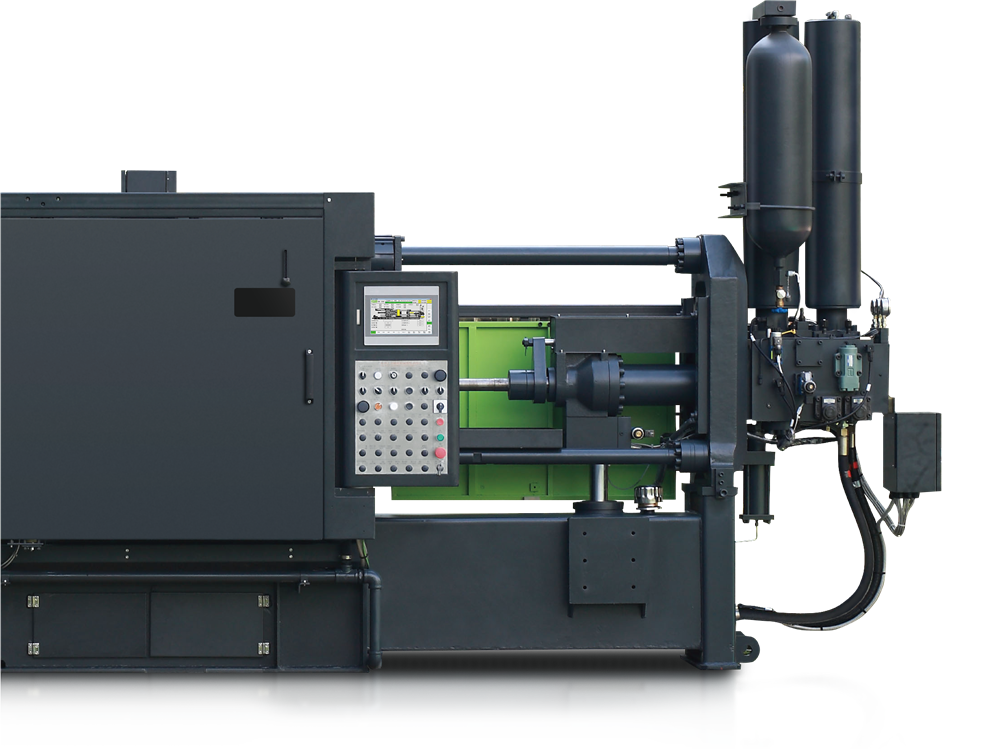

HII Series Cold Chamber Die Casting Machine(180-900T)

Engineered for peak performance, the HII Series merges YIZUMI’s expertise with human-centric innovation. The intuitive HMI of this cold chamber die casting machine enhances operational efficiency, while advanced hydraulics shorten cycle times and cut energy use. Precision-cast components benefit from reduced pressure build-up, high-speed acceleration, and global-standard repeatability.

Available with die locking forces from 180T to 900T.

Available with die locking forces from 180T to 900T.

Safe and Reliable

Precise and Stable

Efficient and Durable

Wide Range of Application

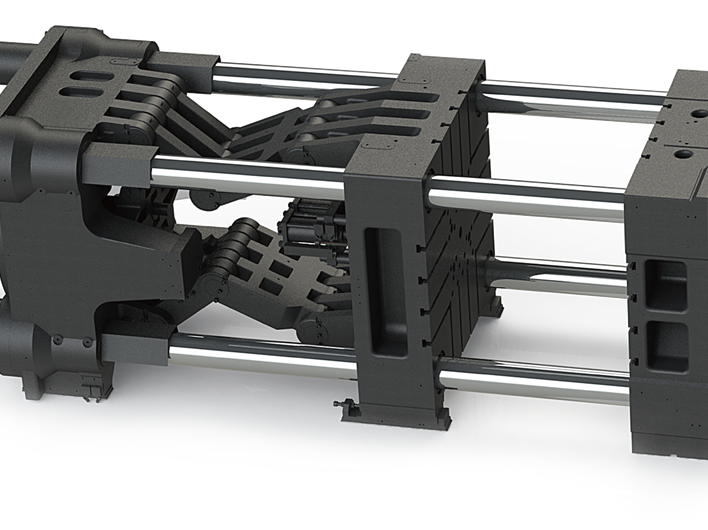

Clamping Unit

Re-Designed high rigidity

- Further increased platen rigidity protects the die casting tools during operation;

- A new design based on FEM analysis offers an even distribution of force by minimizing platen bending.

- A new design based on FEM analysis offers an even distribution of force by minimizing platen bending.

Designed for extended service life

- Re-designed toggle geometry based on detailed movement simulations provides improved platen movement characteristics;

- Which extends toggle service life and further decreases closing and opening time.

- Which extends toggle service life and further decreases closing and opening time.

Optimized Toggle Lubrication Design

Improved and centrally located toggle system, lubrication, and grease system ease the operation of the machine so that an extended machine service life is ensured.

Injection Unit

Enhanced shot performance

- With its optimized hydraulic system, the HII system offers a high injection acceleration of up to 50G. In combination with its high-capacity P/Q2 performance, the HII die casting machine is built to provide high casting quality with even the most difficult parts;

- The max. dry injection speed ≥8m/s meets the customer`s high process requirements.

- The max. dry injection speed ≥8m/s meets the customer`s high process requirements.

Higher performance injection hydraulic system

- A new integrated injection hydraulic adds injection performance to improve casting process stability while reducing components and increasing machine availability;

- Precisely triggering the fast-filling phase is critical for many die casting applications. The HII provides a high standard of precision to switchover to the cavity filling phase. The variation is ≤6mm. A repeatability of max +/-2.5mm, which satisfies the highest requirements.

- Precisely triggering the fast-filling phase is critical for many die casting applications. The HII provides a high standard of precision to switchover to the cavity filling phase. The variation is ≤6mm. A repeatability of max +/-2.5mm, which satisfies the highest requirements.

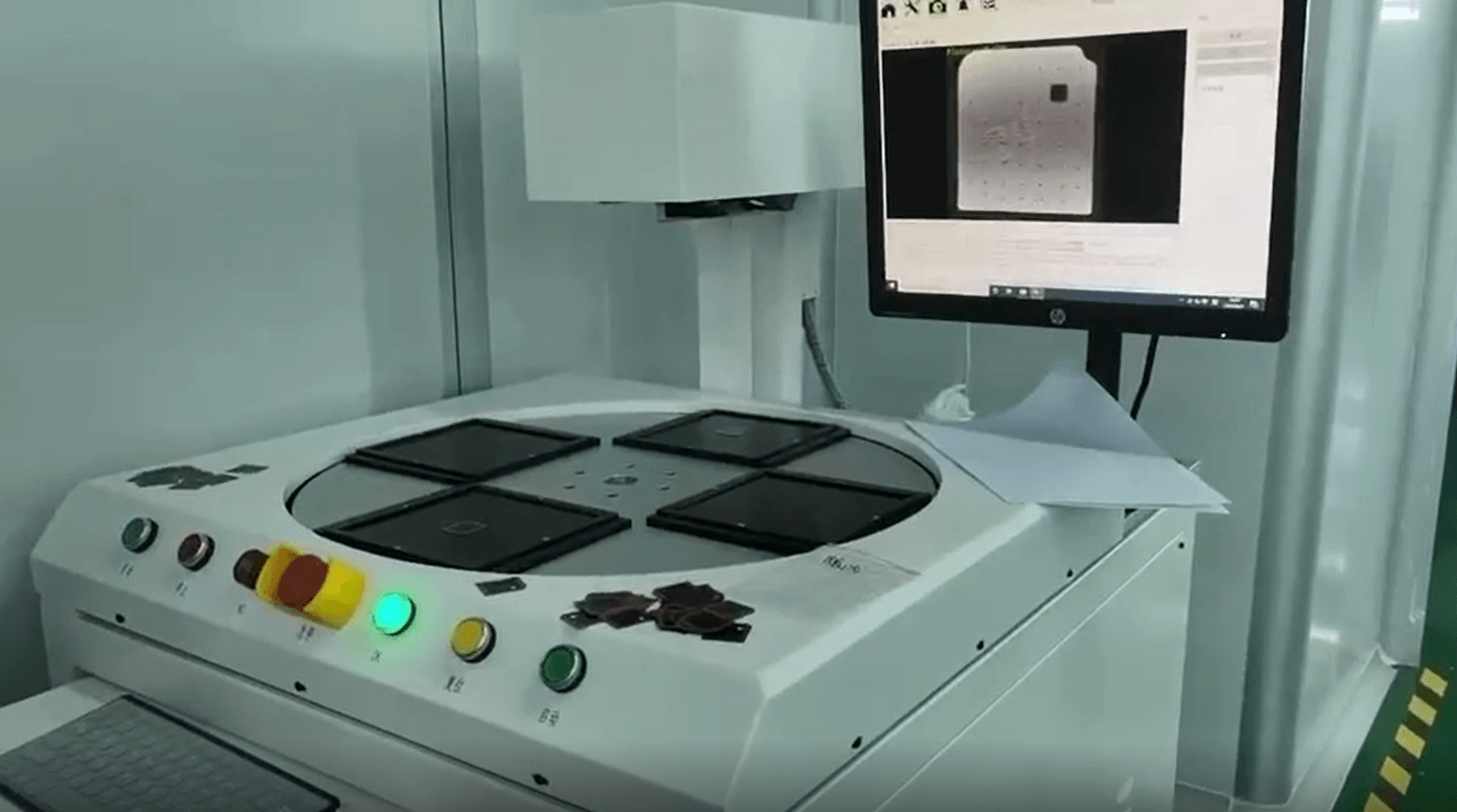

YIZUMI Condition Monitor System (Optional)

Machine Monitor

- The running status is viewed in real time

- Dynamic calculation of operational metrics

- Alarm information is collected in real time

- Timely warning of abnormal downtime

- Dynamic calculation of operational metrics

- Alarm information is collected in real time

- Timely warning of abnormal downtime

Process Monitor

- Process parameters are collected in real time

- Timely warning of parameter anomalies

- Historical processing parameters are traced

- Process parameters SPC control

- Timely warning of parameter anomalies

- Historical processing parameters are traced

- Process parameters SPC control

Production Monitor

- Production progress monitoring

- Quality statistical analysis

- Hourly production statistics

- KPI exception alert

- Quality statistical analysis

- Hourly production statistics

- KPI exception alert

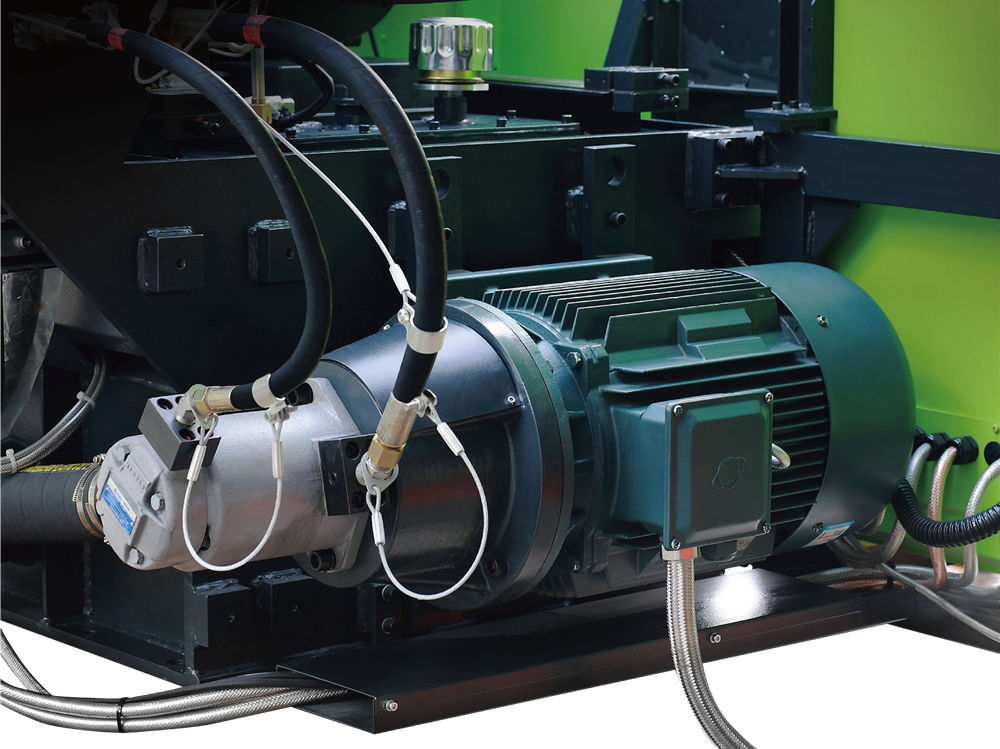

Fast and Precise Hydraulic Drive System

- The third-generation servo drive offers even Less noise emissions if compared to the previous design. System noise reduction of about 20%;

- Stabilizing power surges automatically for up to 5 mins, this system offers great operational stability even with fluctuating main power;

- This efficient servo pump system ensures the lowest possible oil temperatures, further enhancing operational efficiency;

- Reduced system response time improves reaction time and the highest operational performance.

- Stabilizing power surges automatically for up to 5 mins, this system offers great operational stability even with fluctuating main power;

- This efficient servo pump system ensures the lowest possible oil temperatures, further enhancing operational efficiency;

- Reduced system response time improves reaction time and the highest operational performance.

International Standard Electrical Control System

- The integrated operating panel is easy to use and saves time for the operator as well as the casting process engineers;

- Further optimized layout and structure of our HMI increases flexibility in managing machine functions via a large touchscreen;

- Intuitive and easy-to-understand maintenance functions, such as maintenance tips, comprehensive alarm messages, and operation guidance, increase operational efficiency.

- Further optimized layout and structure of our HMI increases flexibility in managing machine functions via a large touchscreen;

- Intuitive and easy-to-understand maintenance functions, such as maintenance tips, comprehensive alarm messages, and operation guidance, increase operational efficiency.

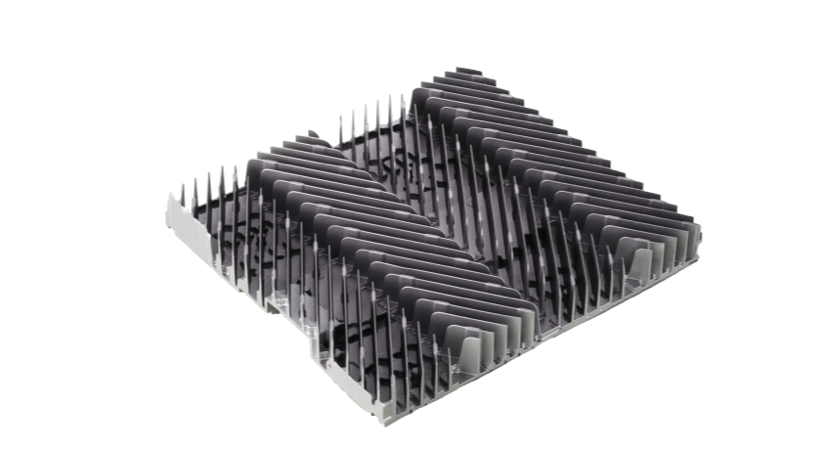

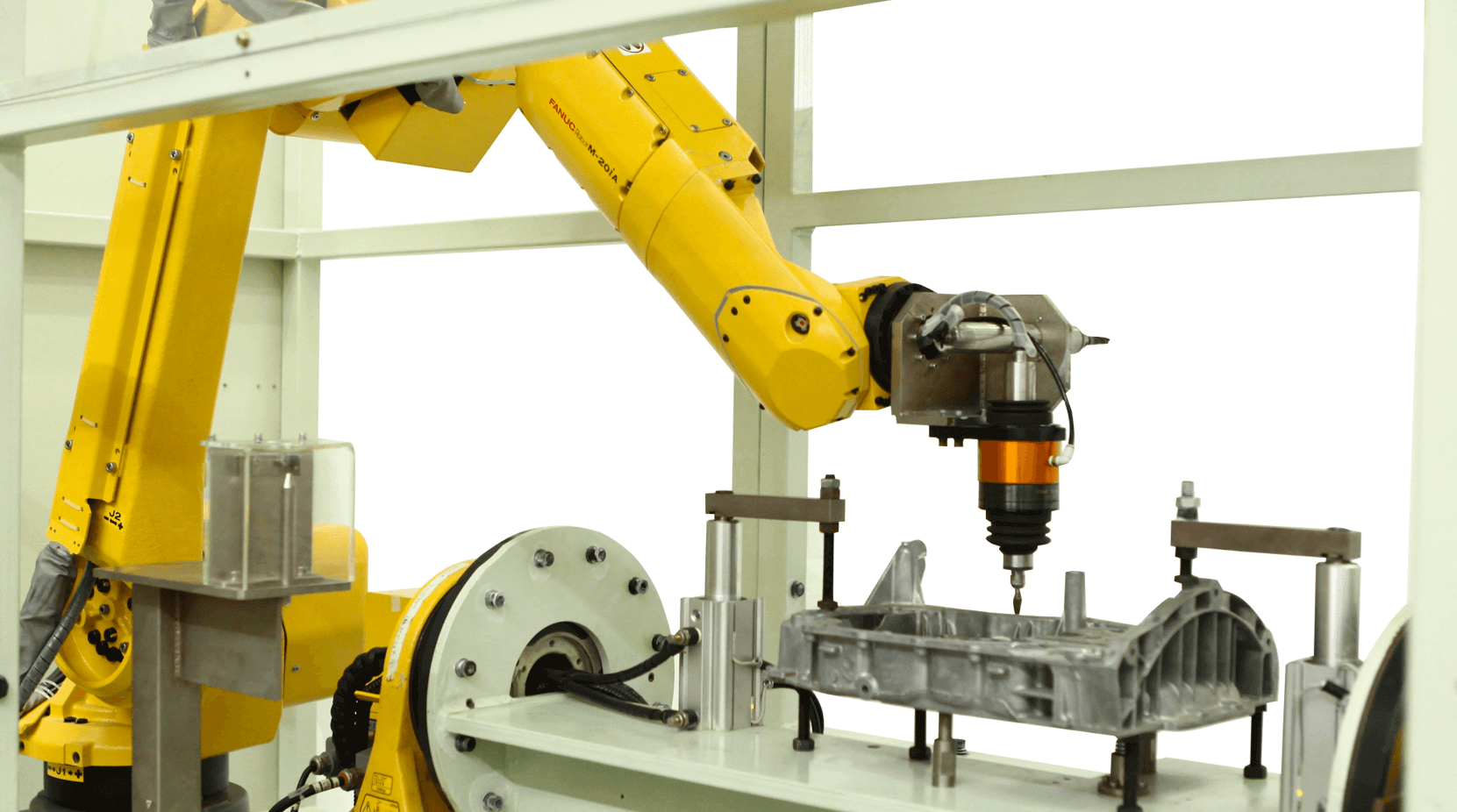

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Relevant Automation

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

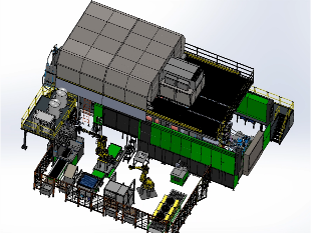

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.