Application Highlights

Innovative Product Design

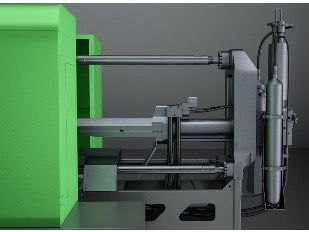

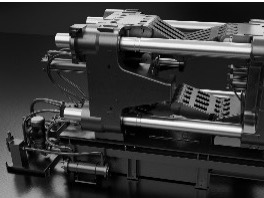

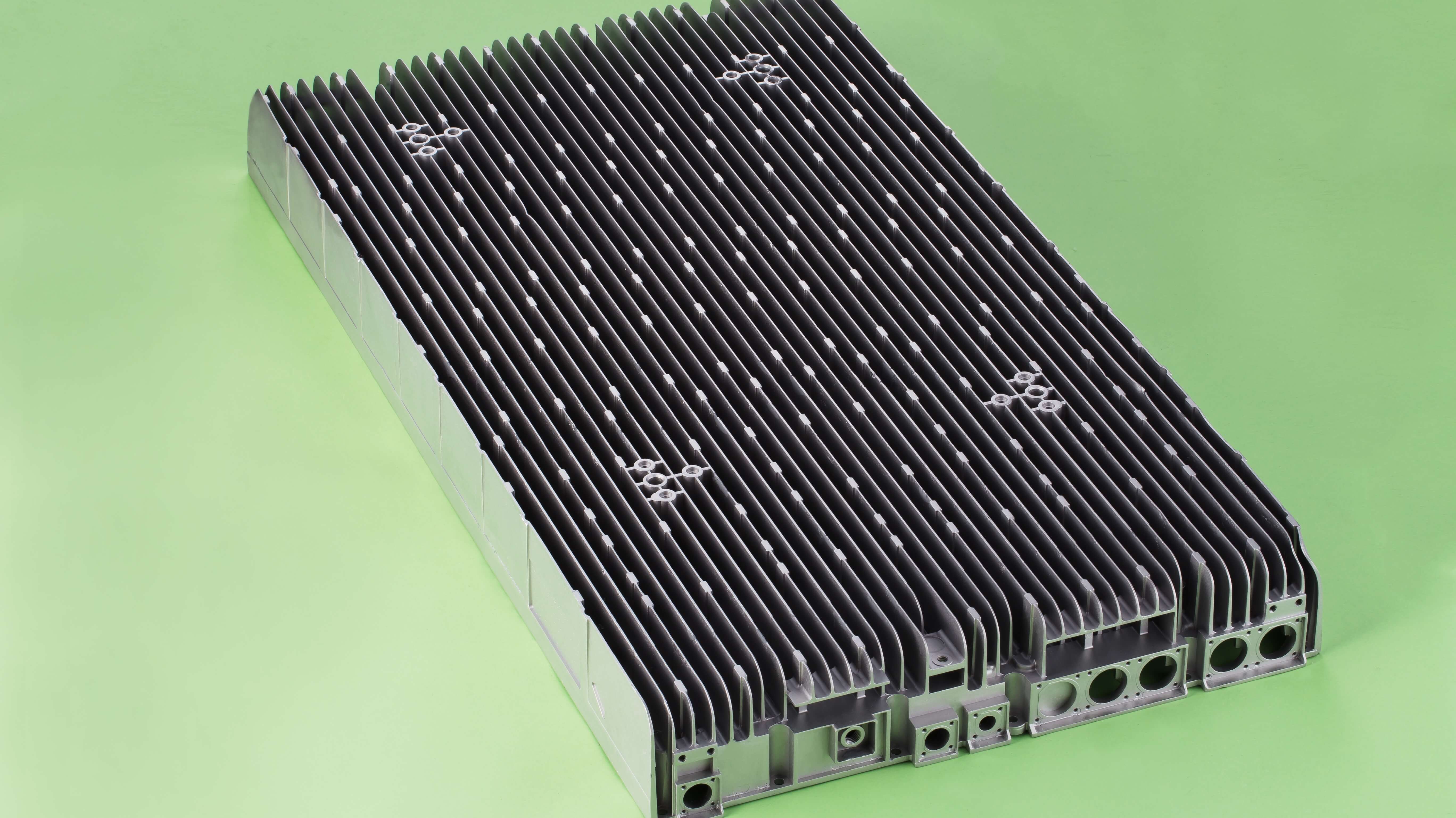

The product structure is getting bigger while the average wall thickness becomes thinner. Some heat sink fins have a height of 80-100mm and a thickness of merely 1mm. The die-casting machines have gradually reached 4500-6000 tons from 1250-2000 tons in the 3G era.

Innovation Advantages

Compared with other processes, die casting allows you to make larger parts, achieve better thermal conductivity and more complex structure. Near Net Shape of housings larger than 1m with uneven thickness can be completed in one step.

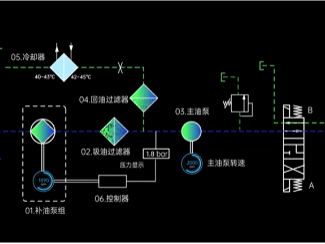

Core Technology

YIZUMI's high vacuum die-casting technology and local compression technologies enable you to perfectly achieve the forming of ultra-high&thin fins with high thermal conductivity materials, fulfilling the requirements for external vision quality and internal denseness of the product: no porosity, shrinkage and blister.

Process Technology

Whether you use the traditional die-casting process, high vacuum die-casting process, or semi-solid-casting process, YIZUMI's experienced process engineers can provide you with full support, making your production worry-free.

5G Base Station Housing Application

Service Process

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

- Product performance

- Product quality

- Ease of use

- Safety requirements

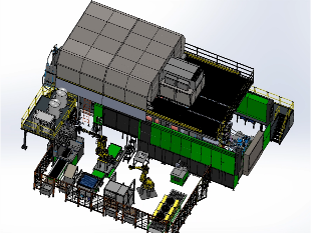

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

- Professional installation and debugging

- On-site operation training

- Molding process training

- YFO services

- Preventive maintenance

- Device upgrade

![[old]LEAP Series Die Casting Machine](/uploads/2022-12-14/71015ea3-f53f-43c6-9176-88fc631e01a11670947886135.png)

![[old] HII-S Series High-end Cold Chamber Die Casting Machine(1000-5000T)](/uploads/2023-06-05/d58e81d3-4969-46b7-801e-b4f2736113071685956662265.png)

![[old] HII-S Series High-end Cold Chamber Die Casting Machine(180-900T)](/uploads/2023-01-05/b67dc467-19d1-4dec-9030-6d6e2faf71d71672908700118.png)