Liquid Silicone Rubber Injection Molding Machine: The Complete Guide

Abstract:

Injection molding has evolved into one of the most reliable ways to manufacture precision components at scale. Among the many materials and methods available today, liquid silicone rubber (LSR) injection molding has carved out a unique place for itself in industries ranging from healthcare and automotive to electronics and consumer goods. Companies that demand high precision, durability, and consistent performance increasingly turn to LSR injection molding machines to meet these expectations.

Injection molding has evolved into one of the most reliable ways to manufacture precision components at scale. Among the many materials and methods available today, liquid silicone rubber (LSR) injection molding has carved out a unique place for itself in industries ranging from healthcare and automotive to electronics and consumer goods. Companies that demand high precision, durability, and consistent performance increasingly turn to LSR injection molding machines to meet these expectations.

This guide takes a deep look into liquid silicone rubber injection molding, its advantages, applications, and how specialized machines—like the LSR Series from YIZUMI—are designed to deliver outstanding performance for commercial and industrial applications.

What Is Liquid Silicone Rubber Injection Molding?

Liquid silicone rubber injection molding is a process that uses specially formulated silicone compounds in liquid form to produce molded components. Unlike traditional thermoplastic molding, which relies on melting solid pellets, liquid silicone molding involves mixing two components (commonly referred to as Part A and Part B) before injecting the mixture into a heated mold. The heat triggers vulcanization, transforming the liquid into a durable, elastic product.

The result is a component that offers excellent flexibility, high thermal stability, and resistance to environmental factors like UV radiation, moisture, and extreme temperatures.

Liquid Silicone Collapsible Lunch Box

Why Businesses Choose LSR Injection Molding

Commercial projects across multiple industries favor liquid silicone rubber injection molding because of the unique material properties and process efficiency it provides.

1. Superior Material Properties

High elasticity and flexibility across wide temperature ranges.

Biocompatibility, making it suitable for medical and food-grade applications.

Long-term stability with resistance to UV light, ozone, and chemical exposure.

2. High Precision Manufacturing

The nature of liquid silicone rubber allows it to flow easily into detailed cavities, enabling manufacturers to create intricate designs and micro-sized parts without defects.

3. Efficiency in Production

Unlike compression molding or extrusion, liquid silicone rubber injection molding machines offer faster cycle times, higher repeatability, and reduced material waste. This efficiency is a crucial advantage for businesses looking to scale production while maintaining consistent quality.

Applications of LSR Injection Molding Machine

The versatility of liquid silicone rubber injection molding is one of its strongest advantages. Industries that demand high performance in challenging environments rely on this technology to produce parts that must remain reliable throughout their lifecycle.

Medical and Healthcare: Catheters, baby bottle nipples, medical seals, and wearable devices benefit from the LSR injection molding machine‘s biocompatibility and resistance to sterilization processes.

Automotive: Gaskets, seals, and connectors withstand high temperatures and aggressive fluids without degrading.

Consumer Goods: Wearable electronics, kitchenware, and lifestyle products require the flexibility and soft-touch feel of liquid silicone rubber.

Electronics: Encapsulation of sensors, waterproof keypads, and protective coverings use liquid silicone rubber injection molding to ensure durability.

LSR Injection Molding Machine For High-Speed Packaging

Key Features of a Liquid Silicone Rubber Injection Molding Machine

Not all injection molding machines are designed to handle liquid silicone. Specialized LSR injection molding machines incorporate technologies and design considerations that optimize performance, efficiency, and product quality.

1. Dedicated Injection Unit

Liquid silicone rubber injection molding machines use a separate injection unit that accommodates the material’s unique properties, such as low viscosity and high flow rate. This ensures precise dosing and consistent quality.

2. Mixing and Blending

The machine mixes Part A and Part B components with additives like pigments. A well-designed screw and mixing system prevents issues such as uneven color distribution, adhesion, or material degradation.

3. Temperature Control

Mold temperature management is essential for consistent curing. Advanced systems provide accurate, visualized control to help operators adjust settings with ease.

4. Leak Prevention

Because liquid silicone is highly fluid, reliable sealing mechanisms are required to prevent leakage and ensure smooth operation from start to finish.

5. Automation Integration

Modern LSR injection molding machines support integration with auxiliary equipment such as silicone feeders, ensuring energy-efficient, precise, and maintenance-free operation.

YIZUMI LSR Series: Precision & Reliability in Liquid Silicone Injection Molding

As the demand for liquid silicone rubber injection molding machines continues to grow, industrial manufacturers look for partners who can provide advanced equipment tailored to modern market needs. YIZUMI’s LSR Series is engineered to deliver efficiency, accuracy, and long-term reliability for businesses across industries.

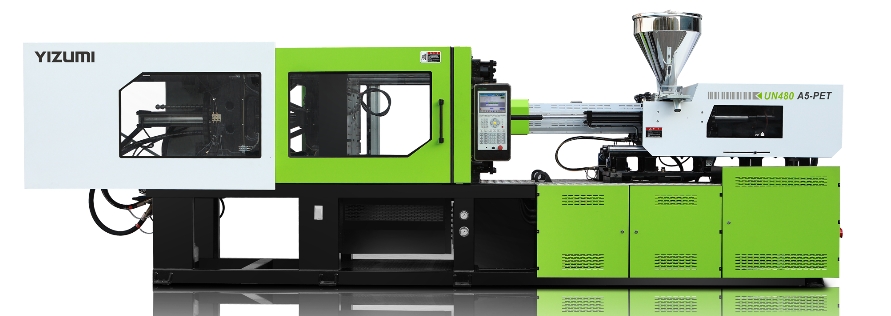

YIZUMI Liquid Silicone Rubber (LSR) Injection Molding Machine

Designed for Advanced Materials

This liquid silicone rubber injection molding machine moves beyond traditional thermoplastic injection molding by accommodating advanced thermoset plastics. With the ability to process both hard (Bakelite/BMC) and soft (LSR) materials, it offers unmatched flexibility for diverse production requirements.

Standard pneumatic injection nozzle: Equipped with water cooling to prevent leakage and premature curing inside the nozzle.

Mixing screw for silicone: Ensures thorough blending of Part A and Part B materials. Sensitive seal rings reduce leakage during injection startup.

Temperature control for mold heating: Built-in visualization system for accurate temperature adjustments. Separate sockets for heating units make setup straightforward.

User-friendly pneumatic system: Standard two-piece filter and fittings make it easy to connect the silicone feeder and air gun directly on-site.

Auxiliary silicone feeder: A fully pneumatic secondary metering system guarantees precision with less than 3% ratio error. It is maintenance-free, waste-reducing, and ensures even color distribution.

Benefits for Businesses

More Efficient: Faster cycle times, higher yield, and minimal waste.

More Professional: Engineered for precision with advanced control and sealing systems.

Customized Design: Tailored configurations available for unique industry needs.

By integrating these features, the YIZUMI LSR Series liquid silicone rubber injection molding machine helps manufacturers produce consistently high-quality silicone products, reduce operating costs, and scale production with confidence.

Choosing the Right LSR Injection Molding Machine

When selecting a liquid silicone rubber injection molding machine, businesses should evaluate the following:

Production Requirements: Volume, part size, and level of complexity.

Material Considerations: Compatibility with specific LSR formulations and additives.

Automation Needs: Integration with feeders, robotics, or quality control systems.

Support and Customization: Choosing a reliable LSR injection molding machine supplier like YIZUMI that offers tailored solutions and technical support can significantly impact long-term success.

Conclusion

Liquid silicone rubber injection molding continues to shape industries that rely on durability, flexibility, and precision. For businesses considering an investment in this technology, choosing the right equipment is crucial. A liquid silicone rubber injection molding machine like YIZUMI’s LSR Series delivers proven performance, efficiency, and customization to meet the evolving demands of commercial production.

With the right machine and partner, companies can produce high-quality silicone products at scale, reduce waste, and maintain consistent quality—making LSR injection molding an essential solution for today’s manufacturing challenges. If you are looking for a professional liquid silicone rubber injection molding machine supplier, please feel free to contact us for tailored solutions!