Cost-Effective Rubber Compression Molding Machine Solutions for Industrial Use

Abstract:

In industrial production, selecting the right rubber processing equipment is crucial for efficiency, quality, and cost management. While injection molding is a popular choice for high-volume rubber components, rubber compression molding machines offer a cost-effective alternative for small to medium batch production. These machines balance investment, operational efficiency, and versatility, making them an attractive solution for businesses seeking reliable rubber processing solutions.

In industrial production, selecting the right rubber processing equipment is crucial for efficiency, quality, and cost management. While injection molding is a popular choice for high-volume rubber components, rubber compression molding machines offer a cost-effective alternative for small to medium batch production. These machines balance investment, operational efficiency, and versatility, making them an attractive solution for businesses seeking reliable rubber processing solutions.

Understanding Rubber Compression Molding

Rubber compression molding is a manufacturing process where pre-measured rubber materials are placed into a heated mold cavity and then compressed under high pressure. This process causes the rubber to flow and fill the mold, curing into a finished product. Different from rubber injection molding, which is better suited for complex, high-volume components, compression molding excels in producing moderate batch sizes with consistent quality. Its straightforward setup and lower tooling requirements make it ideal for industrial users who prioritize cost efficiency and operational simplicity.

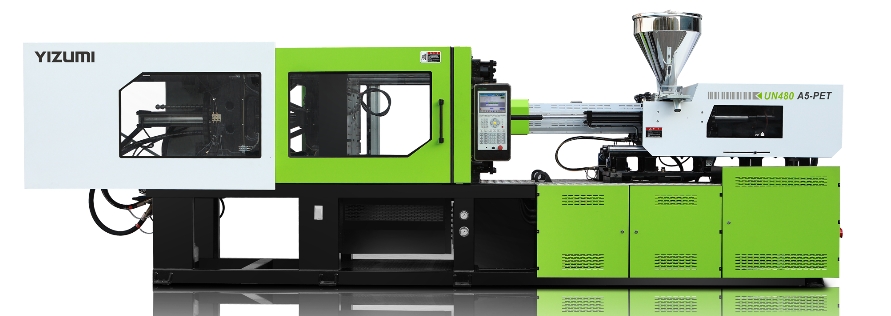

Rubber Injection Molding Solutions

Key Advantages of Rubber Compression Molding Machines

1. Cost-Effective Solution

One of the primary benefits of rubber compression molding machines is their cost efficiency. The machines themselves typically require lower initial investment compared to high-end injection molding systems. Additionally, tooling costs are reduced because molds for compression molding are simpler and easier to maintain. For businesses producing small to medium volumes, this translates to lower upfront and ongoing expenses without compromising product quality.

2. Low Energy Consumption

Modern rubber compression molding machines, like the YIZUMI YL-VV series, are designed for energy efficiency. With optimized heating plates and precise temperature control, energy consumption is minimized while ensuring uniform curing. This not only reduces operational costs but also supports environmentally conscious manufacturing practices.

3. Simple Operation and Maintenance

Rubber compression molding is straightforward to operate. Operators place rubber preforms into molds, close the press, and start the curing cycle. The simplicity of the process reduces the learning curve and minimizes errors. Maintenance is also less demanding than complex injection systems, leading to higher machine uptime and reduced production interruptions.

4. Reliable Product Quality

Compression molding provides consistent part dimensions and material properties. The process ensures uniform pressure distribution, which is crucial for rubber components such as seals, gaskets, and vibration-damping parts. For industrial applications, consistent quality is essential to meet performance standards and reduce waste.

5. Flexibility for Different Batch Sizes

While injection molding is optimized for high-volume production, compression molding machines are particularly suitable for small to medium batch sizes. They allow manufacturers to respond quickly to changing order volumes without significant investment in new equipment or molds.

Industrial Applications

Rubber compression molding machines serve a variety of industrial sectors, including automotive, electronics, and consumer goods. Typical applications include:

Automotive Components: Seals, gaskets, bushings, and vibration isolators.

Electronic Components: Keypads, insulators, and protective covers.

General Industrial Parts: O-rings, washers, and custom rubber components.

In each case, the process provides consistent quality while keeping production costs manageable.

Rubber Injection Molding for Harness Connectors

How to Choose the Right Rubber Compression Molding Machine

Selecting the right machine involves evaluating several factors:

Press Capacity and Pressure Range: Ensure the machine can handle the size and type of rubber parts you intend to produce.

Automation and Control Systems: Advanced systems, such as Siemens controls in YIZUMI machines, improve precision, reduce cycle times, and allow for easy monitoring.

Energy Efficiency: Machines with low energy consumption reduce operating costs and support sustainable production.

Durability and Components: Top-brand hydraulic, electrical, and sealing components enhance reliability and reduce maintenance needs.

Double Working Station Design: Some machines feature dual working stations, allowing simultaneous or independent operation to improve production efficiency.

YIZUMI Rubber Compression Molding Machine

YIZUMI, a leading rubber machinery manufacturer, offers the YL-VV compression press series, specifically designed for cost-effective, small to medium batch production. Key features include:

Low Investment, Simple Operation: Designed to minimize initial costs while maintaining easy operation for industrial use.

High Strength Insulation Plates: Environmentally friendly, durable materials ensure energy-efficient heat retention.

Temperature Holding Capability: Mold temperatures remain stable during heating plate movement, improving curing uniformity.

Rapid Response and Fast Cycle Times: Optimized design allows quicker production without sacrificing quality.

Advanced Siemens Control System: Ensures precise process control, repeatable results, and user-friendly operation.

Top-Brand Components: Reliable international electrical, hydraulic, and sealing parts enhance durability and reduce downtime.

Double Working Station Design: Offers flexibility in production by operating both stations together or independently.

This combination of features makes the YL-VV series rubber compression molding machine an ideal choice for industrial buyers seeking a reliable, cost-effective solution for small to medium batch rubber production.

YUZIMI Rubber Compression Molding Machine

Conclusion

Rubber compression molding machines offer industrial buyers an efficient, cost-effective solution for producing small to medium batch rubber components. With lower initial investment, simple operation, and energy-efficient design, these machines provide a practical and reliable option for industrial rubber production.

YIZUMI’s YL-VV series stands out for its advanced control system, high-quality components, and dual-station flexibility, making it a reliable partner for businesses seeking quality rubber production at a reasonable cost. For industrial buyers focused on value and efficiency, rubber compression molding machines remain a practical choice for consistent, high-quality results.

Frequently Asked Questions (FAQs)

1. Can compression molding handle complex part designs?

Compression molding works best for simpler geometries. For extremely complex or high-precision components, injection molding may be preferable.

2. What is the typical production volume for compression molding?

Compression molding is suitable for small to medium batch production, offering consistent quality without high investment costs.

3. How long is the machine lifecycle?

With proper maintenance and use of high-quality components, rubber compression molding machines like YIZUMI rubber compression molding machine can operate reliably for many years.

4. Can different rubber materials be used?

Yes, compression molding machines handle a variety of rubber types, including natural rubber, silicone, and synthetic compounds.

5. Is dual-station operation efficient?

Dual stations improve throughput by allowing simultaneous production or alternating operation, increasing overall efficiency for batch production.