SpaceA machine - All-In-One Industrial Large Pellet 3D Printing Solutions

Home

Products & Solutions

Polymer Process

SpaceA INDUSTRIAL 3D PRINTING SOLUTIONS

Products

SpaceA industrial 3D printing

SpaceA B-Line Industrial Pellet 3D Printing

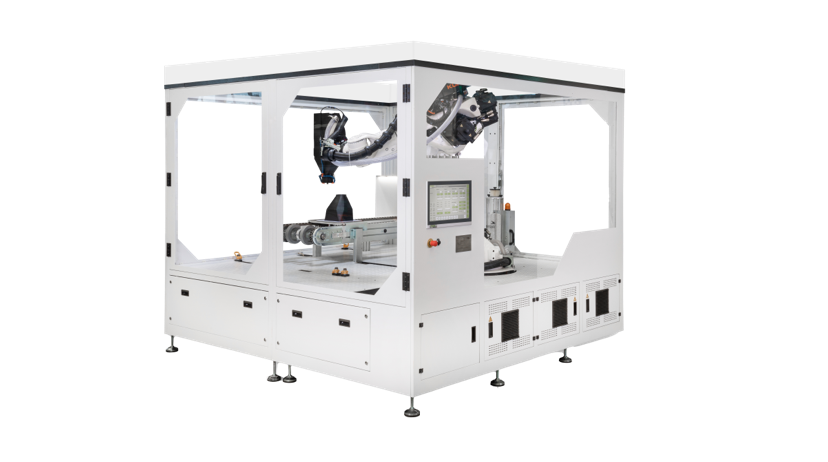

YIZUMI SpaceA B-Line Industrial Pellet 3D Printing Solutions - From 1.6 to 3.9 meters Kuka arm, our popular Beckhoff-based HMI, and currently 2 extruder types and various tables, you can choose your Big Printer.

Big all-in-one solution

Full running system with standard periphery for plastics processing

Freely accessible manufacturing cell

Lean design with many opportunities for various production integration

Big. Bigger. B-Line

High Range up to 3.9 m with high throughput up to 25 kg/h

SpaceA machine - All-In-One Industrial Large Pellet 3D Printing Solutions

SpaceA Technology

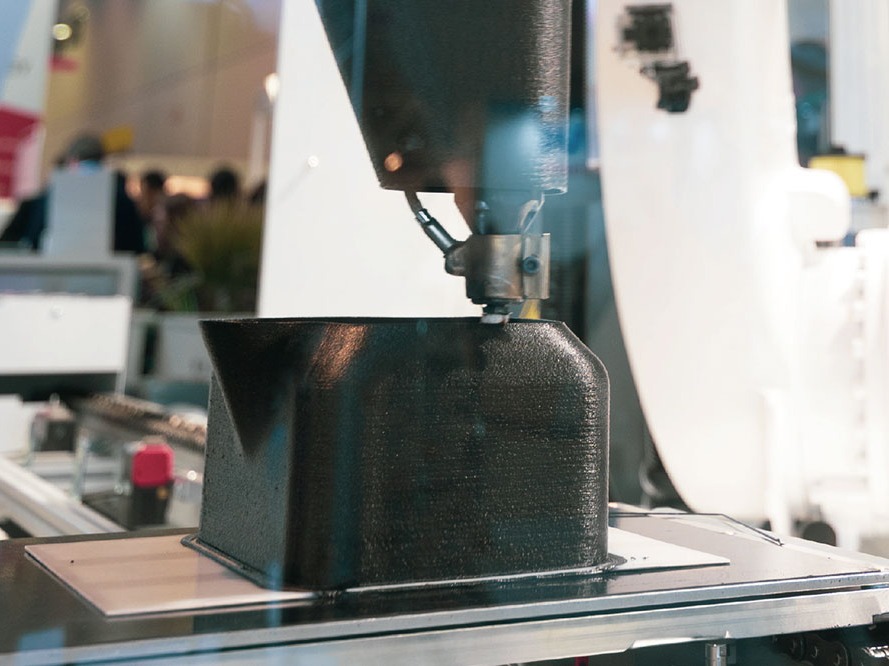

SpaceA technology is based on the layer-by-layer deposition of molten thermoplastic. A solid component can be built by solidifying this melt strand. YIZUMI′s SpaceA technology is based on 4 principles for economical use:

- Use of a screw extruder

- Use of a high plant modularity

- Use of a high plant modularity

- Use of a 6-axis positioning system Use of an industry standard control system

Material Drying

An integrated drying unit can achieve raw material pretreatment.

Single Screw Extruder

Most compact extruder technology with concentric feed zone and integrated drying unit.

Positioning System

A 6-axis robotic system with positioning accuracies of 0.05 mm.

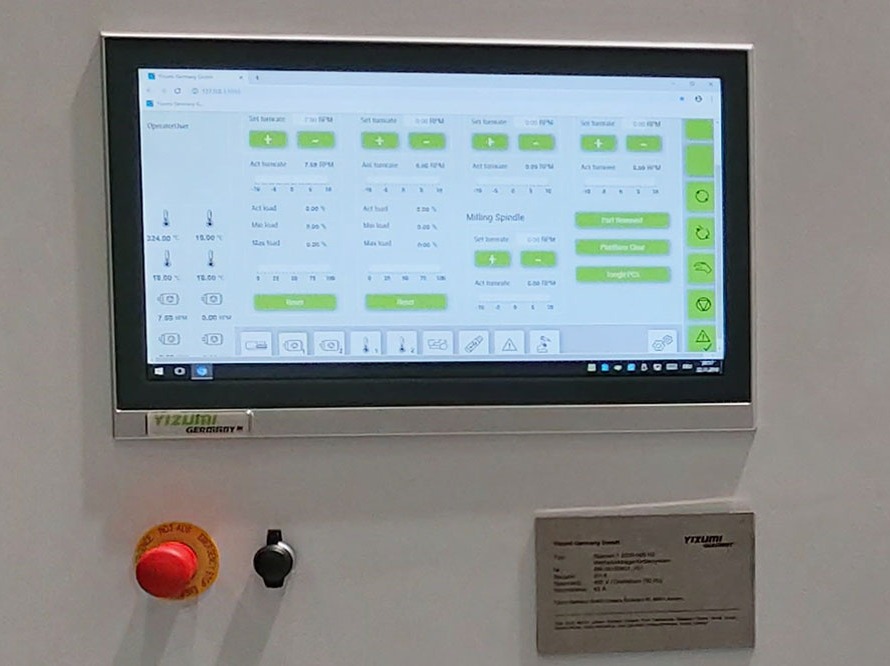

Control on Industry Standard

Higher-level control concept with many interfaces available in the standard version.

Material Diversity

- The screw plasticizing unit is operated with conventional thermoplastic granulate.

- Compared to filament-based production technologies, this enables the processing of unfilled, but also highly filled plastic compounds with simultaneously high and scalable throughputs. The possible high throughput leads to a considerable cost advantage in the processing of engineering thermoplastics. In addition, depending on the material, the low price of granulate (approx. 1 to 8 €/kg) compared to filament (approx. 20 to 500 €/kg) results in a considerable cost reduction potential.

- Compared to filament-based production technologies, this enables the processing of unfilled, but also highly filled plastic compounds with simultaneously high and scalable throughputs. The possible high throughput leads to a considerable cost advantage in the processing of engineering thermoplastics. In addition, depending on the material, the low price of granulate (approx. 1 to 8 €/kg) compared to filament (approx. 20 to 500 €/kg) results in a considerable cost reduction potential.

Productivity & Economical efficiency

- The high productivity of the process used is based on the physical principle of shear heating within the screw extruder. In contrast to the pure plastification via heat conduction, a scalable conveying rate independent of the thermal conductivity of the material can be achieved. Depending on the process point, the throughput rate can be increased to several kilograms per hour.

- Like previous manufacturing processes, additive manufacturing plants must also be subject to the usual investment calculations. Accordingly, the plant investment must be reduced and the material output increased at the same time. Only with high ratios of absolute investment and material output per year can an economic production be guaranteed in comparison to injection molding.

- Like previous manufacturing processes, additive manufacturing plants must also be subject to the usual investment calculations. Accordingly, the plant investment must be reduced and the material output increased at the same time. Only with high ratios of absolute investment and material output per year can an economic production be guaranteed in comparison to injection molding.

Scalability

- The flexibility of the system is based on the separation of the platform module and the print module.

- Thus, a standardized production module can be combined with different platform modules, or several production modules can be combined with one platform module.

- SpaceA, using high module design with print module and platform module, could match different products and systems for flexible production.

- Thus, a standardized production module can be combined with different platform modules, or several production modules can be combined with one platform module.

- SpaceA, using high module design with print module and platform module, could match different products and systems for flexible production.

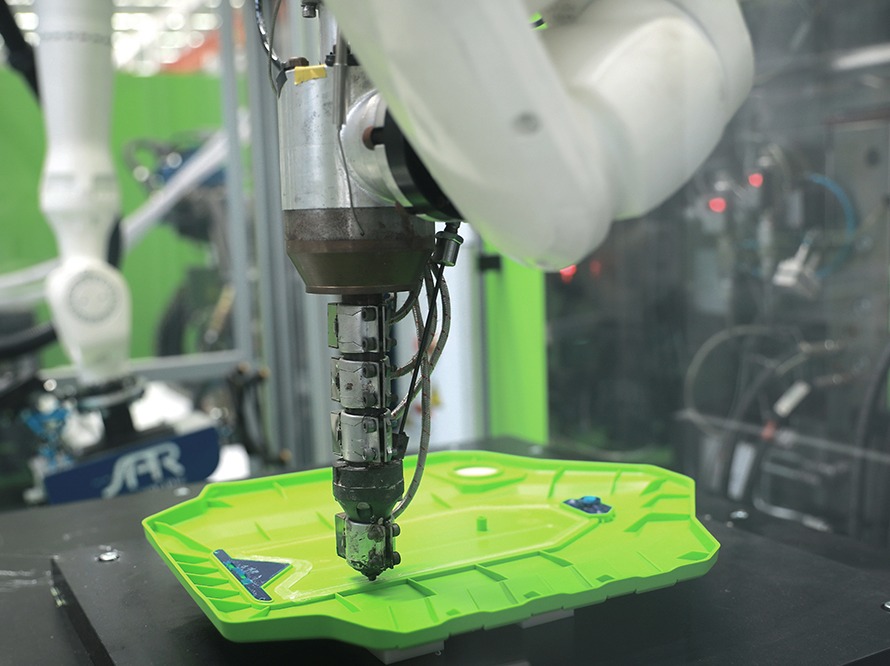

High Potential of Automation

- A 6-axis industrial robot overcomes the usual limitations of component size and design complexity. In order to ensure reproducible dimensional accuracy and high surface quality, and at the same time avoid a restriction of component complexity, subtractive processes are integrated into the manufacturing process by combining additive structure and machining in one manufacturing system.

- Based on this approach, it is also possible to integrate inserts such as threaded or bearing bushes, injection molded parts, electronic or ceramic inserts, and to equip the component to be manufactured with additional functions. For this purpose, the machine used for extrusion and machining operations is equipped with a standardized tool-changing system, which guarantees a high degree of automation and flexibility.

- Based on this approach, it is also possible to integrate inserts such as threaded or bearing bushes, injection molded parts, electronic or ceramic inserts, and to equip the component to be manufactured with additional functions. For this purpose, the machine used for extrusion and machining operations is equipped with a standardized tool-changing system, which guarantees a high degree of automation and flexibility.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.