Sustainable Manufacturing with YIZUMI Injection Moulding Machines: Efficient Production of Household Goods

Abstract:

Discover how YIZUMI's eco-friendly injection moulding machines are revolutionizing the production of household goods like plastic boxes. Learn about their advanced technology, energy efficiency, and sustainability.

Preface:

In today’s manufacturing landscape, sustainability is not just an option—it’s a necessity. As industries worldwide shift toward greener practices, manufacturers seek innovative solutions that align with environmental goals while meeting production demands. YIZUMI, a leading injection machine manufacturer, is at the forefront of this movement, offering injection moulding machines that combine efficiency and sustainability. This article explores how YIZUMI’s injection moulders set new standards in the production of household goods, particularly plastic boxes, through advanced technology and eco-friendly practices.

Section 1: The Initial Situation:

The global demand for household goods, especially plastic products like storage boxes, has surged in recent years. Manufacturers face increasing pressure to produce these items in large volumes without compromising on quality or environmental responsibility. Traditional injection moulding machines often struggle to meet these demands, leading to inefficiencies, higher energy consumption, and increased waste.

Manufacturers are now seeking advanced solutions that allow for scalable production while maintaining sustainability. The need for energy-efficient injection moulding machines that deliver high output with minimal environmental impact is critical. YIZUMI provides an innovative answer to these challenges, offering technology that meets the evolving needs of the industry.

Section 2: Manufacturer Requirements:

For manufacturers of household goods like plastic boxes, the requirements are clear: high efficiency, low energy consumption, and reduced material waste. Injection moulding machines must produce large quantities of products consistently while adhering to stringent environmental standards. Additionally, these machines need versatility to handle various materials and mould designs, enabling manufacturers to quickly adapt to market changes.

Critical to success is the ability to optimize production processes by reducing cycle times, minimizing downtime, and enhancing overall machine performance. Injection moulders that meet these demands are essential for manufacturers aiming to achieve sustainable success in a competitive market.

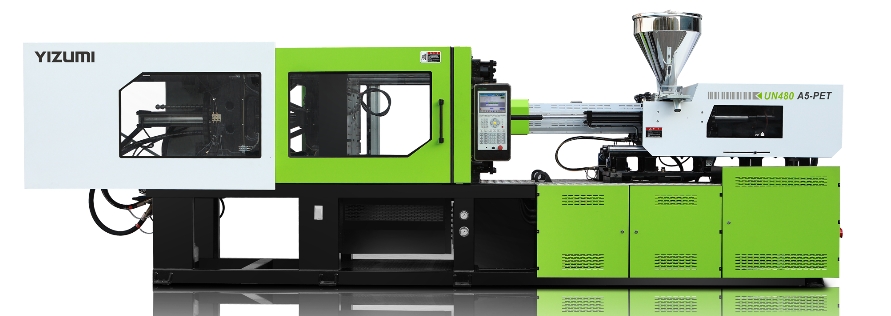

Section 3: YIZUMI Injection Moulding Machines:

YIZUMI’s injection moulding machines are specifically designed to meet the demands of efficient and sustainable manufacturing. The YIZUMI A5-N Series High-end Servo Injection Moulding Machine exemplifies this with its exceptional precision and stability. Offering clamping forces from 65 to 1125 US Tons, it enhances clamping unit rigidity by 30%, ensuring easier mould handling and reducing wear. The integrated linear guide rail structure and horizontal double-carriage design minimize friction, ensuring reliable performance. YIZUMI’s third-generation energy-saving servo technology achieves 30%-80% energy savings compared to conventional machines. The advanced KEBA control system, featuring a 12-inch TFT touch screen, allows precise parameter settings and real-time process analysis, enhancing operational efficiency and flexibility.

Moreover, YIZUMI’s machines are designed for easy maintenance and long-term reliability, reducing the need for frequent repairs and contributing to the sustainability of the production process. By choosing YIZUMI, manufacturers can achieve their production goals while fulfilling their environmental responsibilities.

Section 4: The Solution for Sustainable Manufacturing:

YIZUMI’s injection moulding machines offer the perfect solution for manufacturers looking to balance efficiency with sustainability. These machines are tailored to the specific needs of household goods production, offering a harmonious blend of high output and minimal environmental impact. By leveraging YIZUMI’s technology, manufacturers can streamline production processes, reduce energy consumption, and minimize waste.

YIZUMI’s injection moulders support a wide range of materials, including standard plastics and eco-friendly alternatives, allowing manufacturers to reduce their environmental footprint while maintaining product quality. The machines also support the use of recycled materials, further enhancing their sustainability credentials.

In addition to material flexibility, YIZUMI’s machines are equipped with intelligent control systems that optimize the moulding process by monitoring and adjusting parameters in real time. This level of automation improves efficiency and reduces defects, saving both time and resources.

Section 5: Efficient and Sustainable Production of Household Goods:

To manufacture household goods like plastic boxes efficiently and sustainably, a combination of advanced technology and process optimization is essential. YIZUMI’s injection moulding machines are designed to support these goals by offering features that enhance production efficiency while minimizing environmental impact.

Reducing cycle times is a key strategy for achieving sustainable production. YIZUMI’s machines are engineered to operate at high speeds without compromising quality, enabling manufacturers to produce more units in less time. This increases output and reduces energy consumption per unit, making the production process more sustainable.

Material efficiency is another critical factor. YIZUMI’s injection moulders use precise amounts of material for each product, minimizing waste. The machines also support the use of recycled and bio-based materials, reducing reliance on virgin plastics. By optimizing material usage, manufacturers can simultaneously lower costs and environmental impact.

Finally, YIZUMI’s commitment to sustainability extends beyond the production process, offering comprehensive support services that help manufacturers implement best practices for machine maintenance and process optimization, ensuring long-term efficiency and sustainability.

Conclusion:

YIZUMI’s injection moulding machines offer a powerful solution for manufacturers seeking sustainable success. By combining advanced technology with eco-friendly practices, YIZUMI enables the efficient production of household goods like plastic boxes, helping manufacturers meet both production and environmental goals. As the demand for sustainable manufacturing solutions grows, YIZUMI remains at the forefront of innovation, providing the tools and support needed to drive the industry forward. Whether you aim to reduce your environmental footprint or improve production efficiency, YIZUMI’s injection moulders offer the perfect blend of performance and sustainability.