2024 Rubber Injection Molding Machines: Trends, Buying Guide, and Top Models

Abstract:

Explore the 2024 trends in rubber injection molding machines, discover key buying factors, and find the top models to boost your production efficiency and sustainability.

Preface:

As we move into 2024, the demand for rubber injection molding machines continues to rise, driven by advancements in manufacturing processes and the increasing need for precision in rubber product production. These machines are crucial for producing high-quality rubber components used across various industries, including automotive and healthcare. In this article, we explore the latest 2024 trends in rubber injection molding, provide an in-depth overview of how these machines work, and offer guidance on selecting the best rubber injection molding machine for your needs. We also recommend top models available in the market to help you make an informed purchasing decision.

Section 1: How Rubber Injection Molding Machines Work:

Rubber injection molding machines operate by injecting preheated rubber compounds into a mold cavity under high pressure. The process starts with preparing the rubber material, usually in strips or pellets, which is then fed into the machine's barrel for heating and softening.

Once the rubber reaches the required viscosity, it is injected into the mold cavity through a nozzle. The mold is tightly clamped to prevent material leakage, ensuring that the rubber fills the entire cavity. After curing and solidifying, the mold opens, and the finished product is ejected. The precision and efficiency of this process make rubber injection molding ideal for producing complex shapes and high-volume runs. Modern machines are equipped with advanced control systems that allow precise adjustments in temperature and pressure, ensuring consistent quality across production batches.

Section 2: 2024 Market Trends Analysis:

The rubber injection molding market is experiencing significant growth in 2024, with several key trends emerging:

Automation and Smart Manufacturing: The adoption of automation technologies is increasing as manufacturers look to enhance productivity and reduce labor costs. Rubber injection machines are being integrated with robotics and IoT devices, enabling real-time monitoring and process optimization.

Sustainability: Growing environmental concerns are driving the development of eco-friendly rubber injection machines. Manufacturers focus on reducing energy consumption, minimizing waste, and using sustainable materials in machine construction.

Customization: The rising demand for customized rubber products is leading to the development of machines offering greater flexibility in mold design and material compatibility. This trend is particularly significant in the automotive and healthcare sectors.

Enhanced Precision: Advances in machine design and control systems enable higher precision levels in rubber injection molding, crucial for industries requiring exact specifications, such as medical device manufacturing.

Cost Efficiency: Manufacturers seek rubber injection molding machines that balance performance and cost-effectiveness. This has resulted in a focus on machines that are not only efficient but also easy to maintain and operate.

Section 3: Key Factors for Choosing a Rubber Injection Molding Machine:

Performance: Prioritize machines that deliver a balanced mix of speed, pressure, and temperature control. Consistent performance during extended production runs is essential for maintaining product quality and reducing defects.

Cost: Evaluate the total cost of ownership, including maintenance, energy consumption, and potential downtime. While a lower initial cost may seem appealing, higher operational costs can diminish savings over time. Consider long-term costs for a well-informed investment.

Maintenance: Opt for machines with a robust design that minimizes the need for frequent maintenance. Easy access to components and support services can significantly reduce downtime and repair costs.

Flexibility: Choose a machine that can handle various rubber materials and mold designs, adapting to changing production requirements. Versatility is crucial for businesses needing to manage different product specifications or switch between multiple molds.

Energy Efficiency: With sustainability in mind, select energy-efficient machines that reduce consumption without compromising performance. Advanced temperature control systems and energy-saving technologies are key features to look for.

Brand Reputation: Consider the reputation of the manufacturer. Established brands with a history of reliable, durable machines offer greater confidence in quality and longevity. Research customer reviews and industry feedback to ensure you're investing in a reputable machine.

Section 4: Recommended Model:

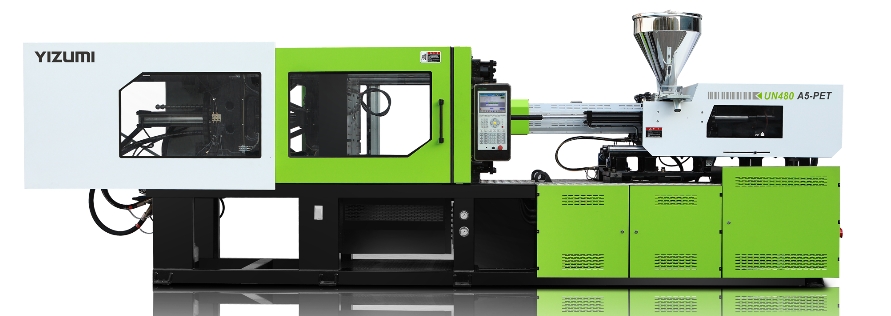

One of the standout models for 2024 is the YIZUMI YL3-VL/F European Series, a high-performance rubber injection molding machine designed for versatility and precision.

The YIZUMI YL3-VL/F European Series is an advanced rubber injection molding machine that meets Industry 4.0 standards. It incorporates the latest core technology, ensuring high precision and reliability through its intelligent components. The machine is user-friendly, with straightforward operation, minimal maintenance, and efficient management. Adhering to European standards, it features deep modularity and cost-effective solutions suitable for European mold installation and demolding methods. The YL3-VL/F includes numerous precision modules and sophisticated software, allowing versatile combinations to address diverse production needs and complex molding processes. Its comprehensive data capabilities support intelligent manufacturing, aiding customers in achieving their business objectives more effectively. Additionally, the machine’s third-generation energy and temperature control system offers significant energy savings, reducing consumption by up to 50%, promoting both economic efficiency and environmental sustainability.

Conclusion:

In 2024, the rubber injection molding market is characterized by advancements in automation, sustainability, and precision. As manufacturers seek efficient and cost-effective solutions, selecting the right machine is crucial. Consider factors like performance, cost, maintenance, and brand reputation when choosing a rubber injection molding machine. The YIZUMI YL3-VL/F European Series is highly recommended for its combination of these attributes, offering an excellent option for manufacturers looking to stay competitive. By staying informed on the latest trends and making well-informed purchasing decisions, you can ensure your business remains at the forefront of innovation in rubber product manufacturing.