Innovations in Rubber Injection Molding

Abstract:

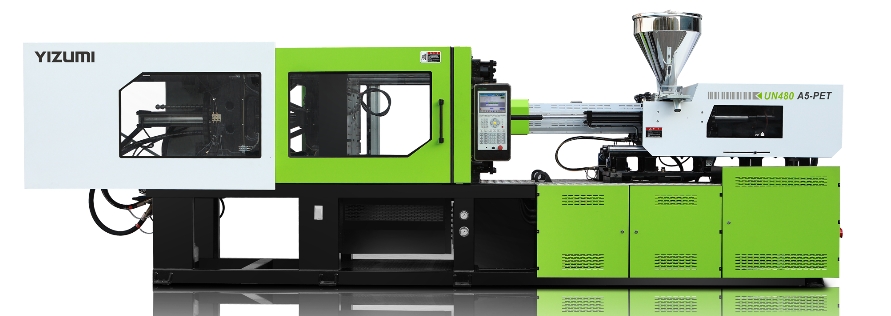

Learn how YIZUMI rubber injection molding machines offer superior precision, energy savings, and robust performance to meet modern industrial demands.

In recent years, rubber injection molding technology?has seen significant advancements, transforming industries that rely on high-performance rubber parts. From automotive to electronics and medical devices, rubber components are integral to product functionality and durability. YIZUMI rubber injection molding?machines, including the YL-VV Compression Press Series, are at the forefront of these innovations, offering cutting-edge solutions that improve efficiency, precision, and product quality.

In this article, we’ll explore how rubber injection molding has evolved, the key material innovations, and how YIZUMI’s advanced machinery supports manufacturers in delivering top-tier products.

Evolution of Rubber Injection Molding Technology

Rubber injection molding?began as a relatively straightforward process, primarily used for creating simple, durable rubber parts. Over time, however, the demand for more complex and precise components led to the development of advanced techniques. Key milestones in the evolution of rubber injection molding include:

1. Increased Material Variety: The use of diverse rubber compounds, including thermoplastic elastomers (TPE) and liquid silicone rubber (LSR), has expanded the scope of molding applications.

2. Improved Molding Techniques: Techniques such as multi-component molding and precision injection have allowed for more intricate designs and higher-quality parts.

3. Automation: Automation of the molding process has reduced labor costs and improved consistency, leading to more efficient production runs.

4. Energy Efficiency: Modern machines, like YIZUMI's YL-VV Compression Press Series, offer energy-saving technologies that lower operational costs.

As these innovations unfolded, the demand for rubber injection molding technology?that delivers both precision and flexibility has never been greater.

Material Innovations

The materials used in rubber injection molding have also evolved significantly, improving product performance, environmental impact, and manufacturing efficiency.

1. Thermoplastic Elastomers (TPE): TPEs combine the processing ease of thermoplastics with the properties of rubbers, allowing for faster cycle times and more versatile applications. The ability to recycle TPE materials also contributes to a more sustainable molding process.

2. Liquid Silicone Rubber (LSR): LSR is increasingly popular in applications requiring high flexibility, heat resistance, and biocompatibility, such as in the medical and electronics industries. Advances in LSR injection molding?have enabled more complex parts to be produced with consistent quality.

3. Eco-Friendly Materials: As sustainability becomes more of a priority in manufacturing, the development of low-emission, environmentally friendly rubbers has accelerated. These innovations help meet growing regulatory requirements while still producing high-quality parts.

YIZUMI supports these material innovations with its YL-VV Compression Press Series, which is capable of handling a range of rubber materials, including eco-friendly options. This versatility ensures manufacturers can adapt to changing material trends while maintaining high performance.

Precision in Design and Engineering

Precision is one of the cornerstones of modern rubber injection molding. From automotive seals to medical device components, many rubber products must meet exacting specifications to ensure proper fit, function, and durability. YIZUMI’s machinery, including the YL-VV Compression Press Series, is engineered to deliver the precision required for these applications.

Key Precision Features Include:

1. Temperature Control: The YL-VV Compression Press Series?maintains precise mold temperatures during heating, ensuring consistent product quality.

2. Injection Control: The system controls the speed, pressure, and temperature of injection, preventing defects such as flash or incomplete fills.

3. Dual Workstations: The machine’s double working station design allows for independent or synchronized operation, enhancing flexibility and productivity.

With these precise engineering features, YIZUMI ensures that manufacturers can achieve the highest level of accuracy in their rubber injection molding?processes.

Enhanced Quality Control and Inspection Techniques

Quality control is a critical factor in rubber injection molding, as small variations in the molding process can lead to significant defects in the final product. Advanced quality control and inspection techniques are essential for maintaining high standards of production.

Modern rubber injection molding technology?integrates several advanced features for superior quality control:

1. Real-Time Monitoring: Automated systems monitor various parameters during the molding process, such as pressure, temperature, and cycle times, to ensure consistency.

2. Post-Molding Inspection: Automated visual inspection systems use cameras and sensors to detect surface defects or dimensional inaccuracies, further reducing the risk of product failure.

3. Data Analytics: Collecting and analyzing data from the molding process helps identify potential issues before they become critical, enabling proactive maintenance and process optimization.

YIZUMI’s YL-VV Compression Press Series?includes an advanced control system that ensures precise operation, offering real-time data monitoring and robust quality control throughout the molding cycle. This results in a consistent, high-quality product every time.

Customization and Color Matching for Branding and Functionality

Another key innovation in rubber injection molding?is the ability to customize the color and branding of molded parts. Whether it’s creating a specific color for a company’s logo or incorporating color-coded features for functional purposes, the ability to easily match colors is a crucial aspect of modern molding technology.

YIZUMI’s YL-VV Compression Press Series?includes features that facilitate precise color matching and customization:

1. Advanced Mixing Systems: The machine’s mixing systems ensure uniform color dispersion and consistent material properties throughout the molding process.

2. Custom Molds: YIZUMI offers custom mold designs to match branding requirements and functional specifications, ensuring seamless integration with a product’s design.

3. Quick Mold Change: The easy and fast mold-change capabilities reduce downtime and improve production efficiency, making it possible to execute custom orders more quickly.

By offering such flexible options, YIZUMI helps manufacturers create products that are not only functional but also visually appealing and consistent with brand identities.

How YIZUMI Innovations in Rubber Injection Molding

YIZUMI has been at the forefront of rubber injection molding technology, with innovative machines like the YL-VV Compression Press Series?helping manufacturers meet modern production challenges. The YL-VV Series?offers several cutting-edge features that optimize performance and reduce costs:

· Energy-Efficient Design: With a focus on low energy consumption and environmental friendliness, the YL-VV Compression Press?helps manufacturers save on operational costs while minimizing their environmental footprint.

· Advanced Control System: The Siemens control system ensures high-speed, precise operation with minimal downtime, and the ability to monitor and adjust parameters in real-time for optimal performance.

· Dual Workstations: The ability to operate both stations independently or together increases flexibility and productivity, making it ideal for high-volume production environments.

These innovations help businesses stay competitive by improving their production efficiency and product quality.

Conclusion

Innovation in rubber injection molding?is not just about improving existing processes but about exploring new materials, achieving greater precision, and integrating advanced technology to optimize production. YIZUMI’s YL-VV Compression Press Series?exemplifies this approach, combining energy efficiency, advanced control systems, and flexible design to meet the evolving needs of manufacturers.

As industries continue to demand higher performance, lower costs, and improved sustainability, YIZUMI?remains committed to providing the most advanced and reliable rubber injection molding solutions. Through continuous innovation, we help manufacturers achieve unparalleled success and set new standards for quality and efficiency in their operations.