Comprehensive Guide to Rubber Injection Molding

Abstract:

Explore the basics of rubber injection molding and how YIZUMI's YL2-VL/F Asian series enhances manufacturing with its versatile, energy-efficient technology, ideal for various industrial applications.

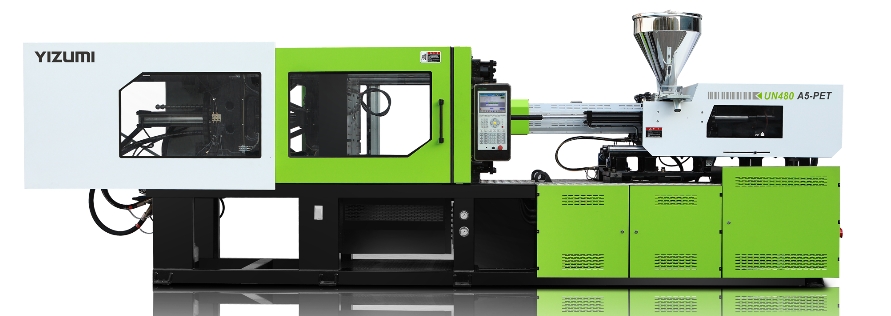

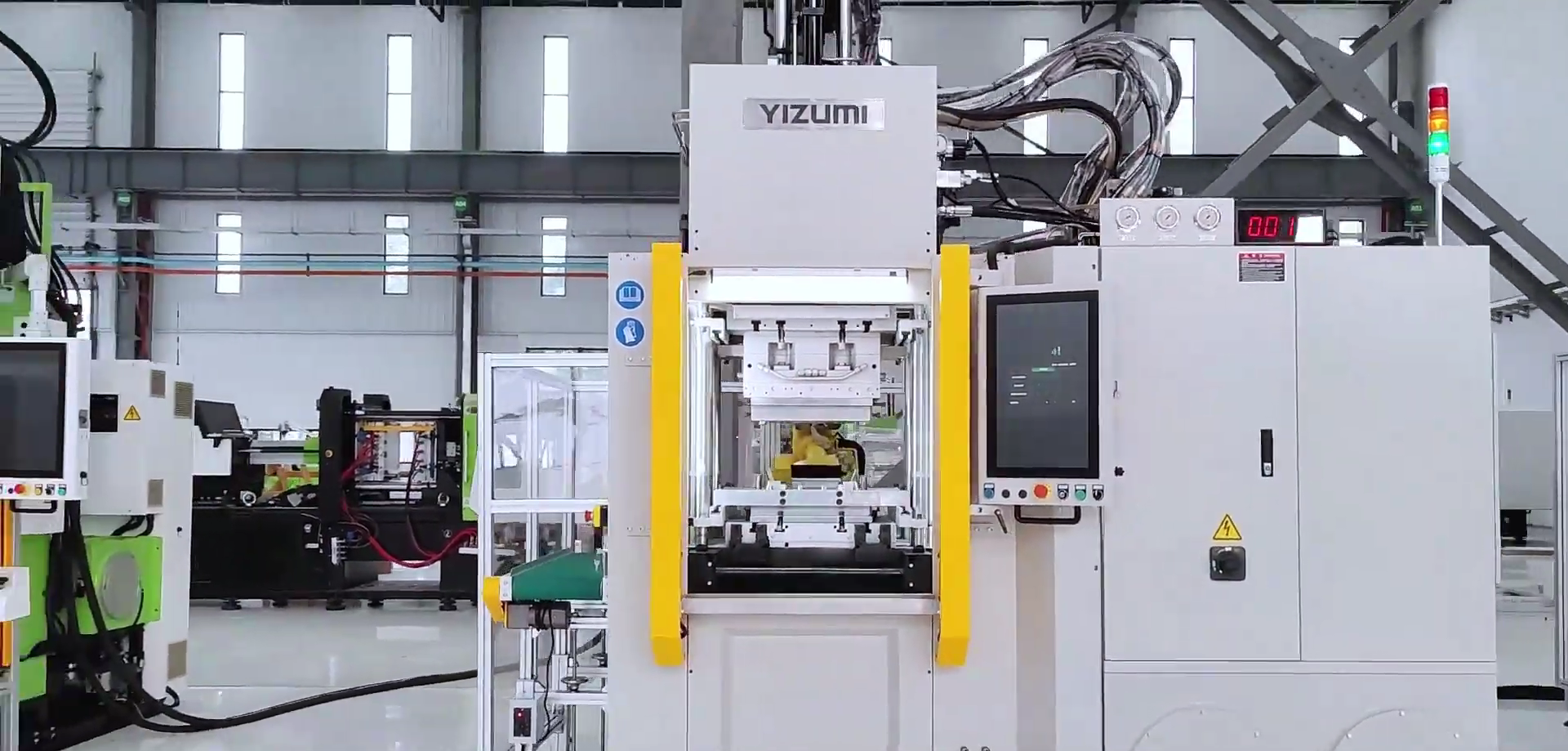

Rubber injection molding has become a cornerstone in modern manufacturing, offering unmatched precision and efficiency for creating high-quality rubber components. As industries demand cost-effective solutions without compromising quality, innovations like YIZUMI rubber injection molding?are leading the way. Our YL2-VL/F Asian series?is designed to meet diverse industrial requirements, delivering superior performance while minimizing costs.

In this comprehensive guide, we’ll delve into the basics of rubber injection molding, its advantages, applications, and the future trends that are shaping the industry.

What is Rubber Injection Molding?

Rubber injection molding is a highly effective manufacturing process used to produce complex and durable rubber components with precision.

The process involves injecting specially formulated rubber materials, such as thermosetting rubbers or elastomers, into a mold cavity under controlled high pressure and temperature. This ensures that the rubber material flows smoothly and fills the mold completely, taking on the exact shape and dimensions required. Once injected, the rubber is allowed to cure, solidifying into its final form.

This method is particularly valued for its ability to create intricate designs, achieve tight tolerances, and ensure consistent product quality across large production runs. The precision and repeatability of rubber injection molding make it ideal for manufacturing high-performance components used in industries such as automotive, medical devices, electronics, and consumer goods.

Key Features of Rubber Injection Molding:

· High precision for complex designs.

· Enhanced efficiency for large production volumes.

· Ideal for diverse industries such as automotive, medical, and consumer goods.

YIZUMI rubber injection molding technology, particularly the YL2-VL/F Asian series, excels in delivering consistent results, even for the most demanding applications.

Types of Rubber Used in Injection Molding

1. Natural Rubber: Offers excellent elasticity and tensile strength, ideal for vibration dampening components.

2. Nitrile Rubber: Resistant to oils and chemicals, commonly used in automotive seals and gaskets.

3. Silicone Rubber: Known for its flexibility, biocompatibility, and heat resistance, widely applied in medical and food-grade products.

4. Other Specialty Rubbers: Includes EPDM, fluoroelastomers, and thermoplastic elastomers for specific industrial needs.

The YL2-VL/F Asian series?accommodates various rubber types, ensuring compatibility with traditional Asian mold designs and providing flexible solutions across industries.

Rubber Injection Molding Process

The rubber injection molding process?consists of several key steps:

1. Material Preparation: Rubber compounds are prepared and preheated for easier flow during injection.

2. Injection: The heated rubber is injected into a pre-designed mold cavity under high pressure.

3. Curing: The material cures within the mold, taking on its final shape and properties.

4. Demolding: The molded component is removed from the mold, ready for finishing or immediate use.

YIZUMI’s YL2-VL/F Asian series?simplifies this process with modular designs and optional demolding devices, enabling efficient molding and demolding even for complex products.

Advantages of Rubber Injection Molding

1. Precision and Consistency

Rubber injection molding ensures exact replication of intricate designs, with minimal waste.

2. Cost-Effectiveness

Efficient production methods and material usage reduce overall costs.

3. High Durability

Components produced through this process exhibit superior strength and longevity.

YIZUMI’s YL2-VL/F Asian series?enhances these advantages with energy-saving systems, reducing power consumption by up to 50% while maintaining excellent performance.

Applications of Rubber Injection Molding

Rubber injection molding finds applications across numerous industries:

1. Automotive Industry

Used for seals, gaskets, and vibration dampening components.

2. Medical Industry

Creates biocompatible parts like surgical instruments and tubing.

3. Consumer Products

Applies to household appliances, electronics, and sports equipment.

4. Industrial Uses

Includes parts for machinery, oil and gas, and construction equipment.

The versatility of the YL2-VL/F Asian series?makes it suitable for all these applications, with a focus on performance and adaptability.

Challenges of Rubber Injection Molding

Despite its benefits, rubber injection molding presents certain challenges:

· Material Flow Control: Managing flow for consistent filling without defects.

· Temperature Sensitivity: Maintaining precise curing temperatures to avoid part failure.

· Complex Molds: Handling intricate molds requires advanced machinery and expertise.

YIZUMI addresses these challenges with innovations in machine design, such as optimized piston installation structures for quick compound changes and advanced energy control systems for consistent temperature management.

Custom Rubber Injection Molding

For businesses with unique requirements, custom rubber injection molding offers tailored solutions. YIZUMI excels in providing modular designs and flexible options in our YL2-VL/F Asian series?to accommodate complex traditional molding processes.

Key Features:

· Modular injection units for versatility.

· Easy-to-disassemble pistons for efficient maintenance.

· Rational machine layouts for optimized operation spaces.

These features ensure that our machines meet the specific needs of diverse industries, delivering high performance and reliability.

Future Trends in Rubber Injection Molding

As industries continue to evolve and become more technologically advanced, the demand for more sophisticated and efficient rubber injection molding technology grows.

With the increasing complexity of designs, higher performance requirements, and the need for greater production efficiency, manufacturers are seeking cutting-edge solutions that can meet these challenges.

Advanced molding technologies offer improved precision, faster cycle times, better material handling, and enhanced energy efficiency, enabling businesses to stay competitive in an ever-changing market.

1. Sustainability: Emphasis on eco-friendly materials and energy-efficient processes.

2. Automation: Increasing use of AI and IoT for real-time monitoring and control.

3. Customization: Greater focus on personalized solutions for niche applications.

4. Globalization: Expanding accessibility of innovative molding technologies worldwide.

YIZUMI?remains committed to staying ahead of these trends, offering advanced solutions that address the challenges of tomorrow’s manufacturing landscape.

FAQs About Rubber Injection Molding

Q1: What is the primary benefit of rubber injection molding?

A: It ensures precision and efficiency for complex, high-volume production.

Q2: Can YIZUMI machines handle various rubber types?

A: Yes, our YL2-VL/F Asian series?supports multiple rubber materials, offering versatility for diverse applications.

Q3: How does YIZUMI ensure energy efficiency?

A: Our 3rd-generation energy control system reduces power consumption by up to 50%, optimizing operational costs.