Automation and Robotics in Injection Molding: Enhancing Efficiency and Productivity

Abstract:

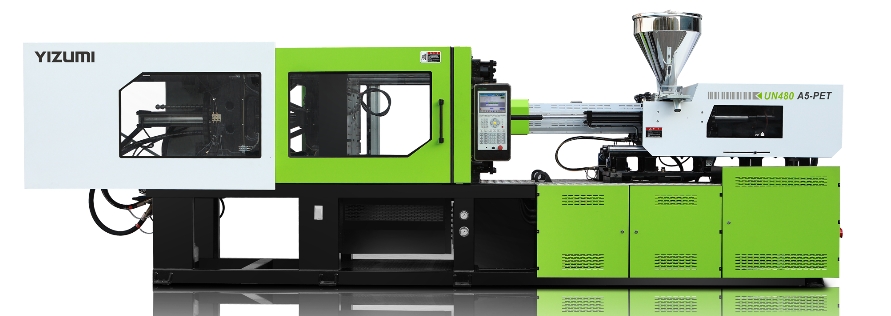

Automation and robotics are transforming injection molding, enhancing efficiency and precision. YIZUMI's FF Series Electric Injection Molding Machine offers advanced automation and all-electric technology for superior quality and cost-effectiveness.

Automation and robotics have transformed modern manufacturing, making processes faster, more accurate, and highly efficient. The injection molding industry, in particular, has seen remarkable advancements due to the integration of robotics and automation. As manufacturers strive for higher productivity and precision, all-electric injection molding machines are becoming essential for achieving seamless, intelligent production.

YIZUMI, a leader in injection molding technology, continues to drive innovation with solutions that enhance efficiency, reduce waste, and improve product quality. Our FF Series Electric Injection Molding Machine?exemplifies this commitment, offering unmatched precision, flexibility, and automation capabilities.

Why Automation and Robotics Matter in Injection Molding

The adoption of automation and robotics in injection molding is not just about reducing labor costs—it's about increasing production efficiency, improving quality control, and minimizing material waste. Key benefits of automation in injection molding include:

· Increased Production Speed – Automated systems reduce cycle times and ensure continuous operation.

· Enhanced Precision and Consistency – Robotics minimize variations and defects, resulting in higher-quality molded parts.

· Reduced Material Waste – Advanced process control ensures efficient use of raw materials.

· Improved Workplace Safety – Automation eliminates human exposure to hazardous areas.

· Seamless Integration with Smart Manufacturing – AI and data-driven analytics optimize production processes.

With these advantages, automated injection molding has become a necessity for manufacturers looking to stay competitive in a rapidly evolving industry.

Key Robotics and Automation Technologies in Injection Molding

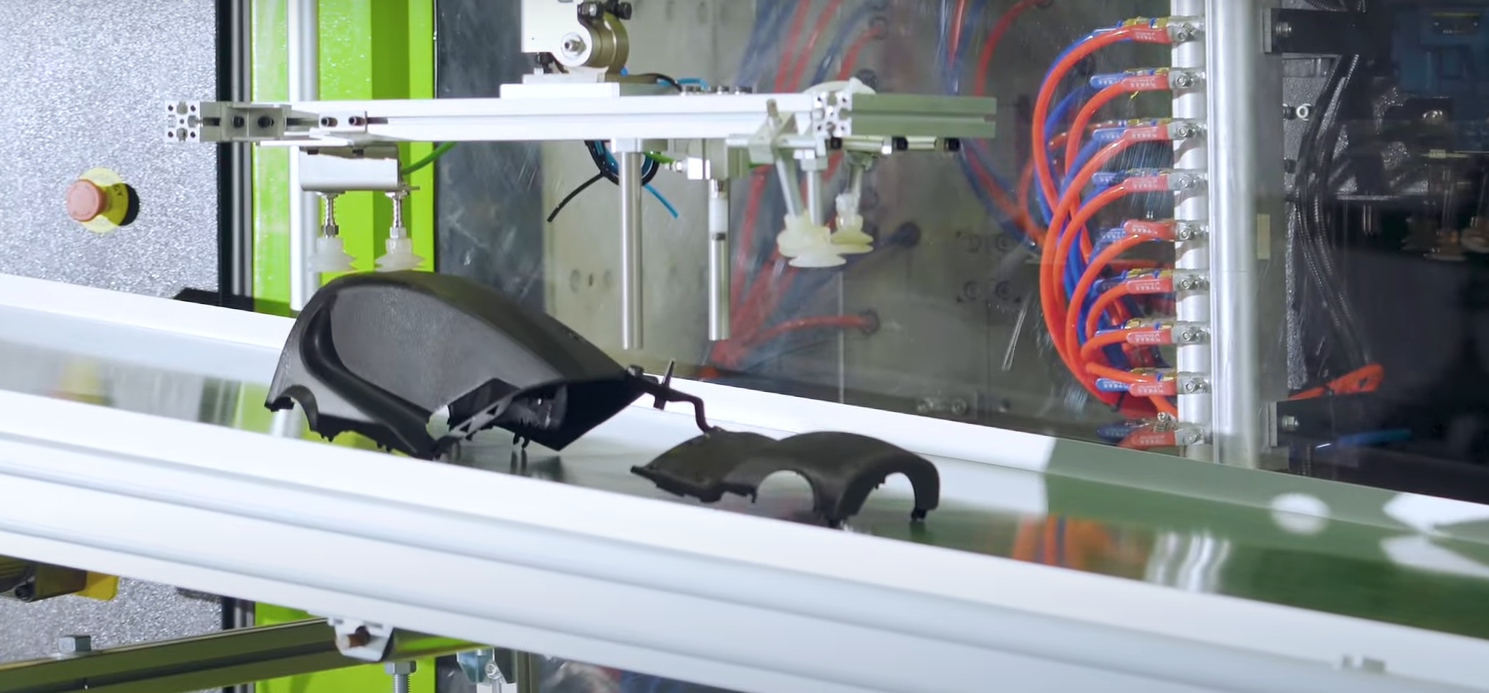

1. Robotic Part Handling and Removal

Automated robotic arms have replaced manual part handling in injection molding. These robots:

· Extract molded parts efficiently?without human intervention.

· Reduce cycle time?by synchronizing with the machine's operation.

· Prevent part damage?by ensuring controlled removal and placement.

2. Automated Quality Inspection

AI-powered vision systems and sensors have revolutionized quality control in injection molding by:

· Detecting defects in real time, reducing waste.

· Ensuring precise measurements, improving product consistency.

· Providing detailed data analytics, allowing manufacturers to optimize processes.

3. Smart Control Systems and Digitalization

Modern injection molding machines feature intelligent control systems?that:

· Monitor real-time performance metrics, predicting maintenance needs.

· Adjust injection parameters autonomously, optimizing production efficiency.

· Enable remote operation and diagnostics, reducing downtime.

4. Advanced Multi-Axis Servo Motors

The integration of multi-axis servo motors allows:

· Faster, more precise control of injection, clamping, and ejection movements.

· Energy-efficient operations, reducing power consumption.

· Higher repeatability, ensuring consistency in high-volume production.

How YIZUMI is Leading the Automation Revolution in Injection Molding

At YIZUMI, we have embraced automation and robotics to enhance the capabilities of our injection molding machines. Our FF Series Electric Injection Molding Machine?is designed to meet the increasing demands for precision, efficiency, and smart manufacturing integration.

FF Series Electric Injection Molding Machine: Redefining Efficiency

Our FF Series?surpasses traditional machine standards, seamlessly integrating automation and intelligent control systems?for improved quality and operational efficiency. This all-electric injection molding machine delivers:

1. Stability and Precision for Complex Molding

· Dual-cylinder parallel ejection design?ensures uniform force application, enhancing mold release.

· Precision ejection position accuracy of up to 0.2mm, improving repeatability.

· Advanced mold protection technology, preventing damage and ensuring longer mold life.

2. Intelligent Injection Unit for Maximum Efficiency

· LGS (Linear Guide Support) technology?enhances rigidity, eliminating unnecessary friction.

· Closed-loop injection pressure control?ensures precise and repeatable injection.

· Servo direct control (SDC) technology, with four independent servo motors for faster feedback and more accurate control.

3. Smart Control for Seamless Automation

The European KEBA2000 Controller?elevates smart manufacturing capabilities with:

· Real-time quality monitoring, optimizing production efficiency.

· Centralized remote operation, allowing full control over multiple machines.

· Flexible I/O expansion, enabling additional automation features as needed.

With these innovations, YIZUMI injection molding machines help manufacturers achieve higher production efficiency, lower energy consumption, and reduced defect rates.

Future Trends in Automation and Robotics for Injection Molding

The future of injection molding will continue to be driven by automation, digitalization, and AI-powered smart manufacturing. Key trends include:

· Increased Use of AI and Machine Learning – Automated systems will further refine production by predicting defects and adjusting parameters in real time.

· Integration of IoT in Injection Molding Machines – Real-time data collection will improve machine performance and predictive maintenance.

· Greater Adoption of All-Electric Injection Molding Machines – As manufacturers seek sustainability, energy-efficient electric machines will dominate the industry.

· Expansion of Collaborative Robotics (Cobots) – Human-robot collaboration will improve safety and efficiency in production environments.

FAQ

1. What are the advantages of an all-electric injection molding machine over hydraulic machines?

All-electric machines, like YIZUMI's FF Series, offer higher energy efficiency, precise control, reduced noise, and faster cycle times?compared to hydraulic machines. They also require less maintenance?and produce minimal waste.

2. How does automation improve injection molding efficiency?

Automation reduces cycle time, enhances precision, and minimizes human errors, leading to higher productivity and consistent product quality. Smart systems also enable real-time monitoring and optimization.

3. Can YIZUMI's FF Series Electric Injection Molding Machine integrate with existing automation systems?

Yes, our machines are designed for seamless integration?with robotics, AI-driven analytics, and smart factory systems, making automation implementation easy for manufacturers.

4. How does YIZUMI's servo direct control (SDC) technology benefit injection molding?

Our SDC technology uses four independent servo motors?to control injection, plasticizing, clamping, and ejection with higher accuracy, faster response times, and improved energy efficiency.

5. What industries benefit the most from automated injection molding?

Automated injection molding is widely used in automotive, medical, electronics, consumer goods, and packaging industries, where precision, high production rates, and cost efficiency?are critical.

Automation and robotics have become essential in modern injection molding, significantly enhancing efficiency, precision, and cost-effectiveness. YIZUMI's FF Series Electric Injection Molding Machine?embodies the future of smart manufacturing, integrating advanced automation, AI-driven controls, and energy-efficient technology.

For manufacturers looking to improve productivity, reduce waste, and enhance product quality, investing in an all-electric injection molding machine is the key to long-term success. YIZUMI?remains at the forefront of this transformation, delivering cutting-edge solutions that redefine the industry's standards.