All-Electric Injection Molding Machines: Achieving High Precision & Cleanroom Standards

Abstract:

In competitive manufacturing landscape, the demand for high-precision, energy-efficient, and contamination-free molding solutions is growing rapidly—especially in industries like medical, electronics, and precision automotive components. At the center of this evolution is the all-electric injection molding machine—a technology transforming the standards for quality, performance, and cleanroom compatibility.

In today’s competitive manufacturing landscape, the demand for high-precision, energy-efficient, and contamination-free molding solutions is growing rapidly—especially in industries like medical, electronics, and precision automotive components. At the center of this evolution is the all-electric injection molding machine—a technology transforming the standards for quality, performance, and cleanroom compatibility.

What Is an All-Electric Injection Molding Machine?

Unlike traditional hydraulic models, an all-electric injection molding machine uses electric servo motors to power every stage of the molding process, including injection, clamping, metering, and ejection. This design eliminates hydraulic oil entirely, resulting in a cleaner, more energy-efficient, and more precise molding environment.

With the push for smart manufacturing and eco-conscious production, all-electric models have become the preferred choice in industries requiring consistency, hygiene, and micron-level precision.

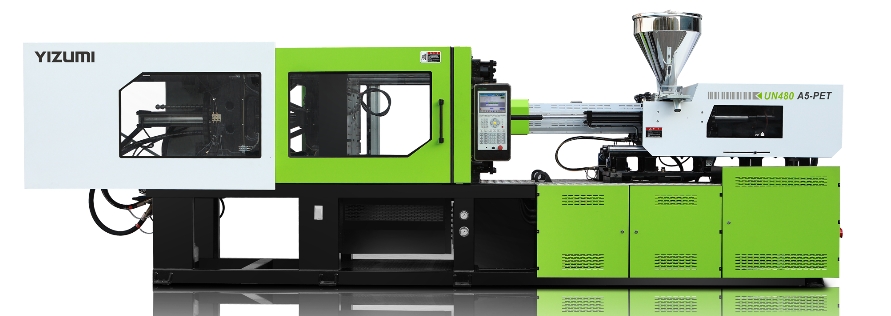

All-electric Injection Molding Machine Manufacturer

Why Precision Matters in Modern Injection Molding

Precision is critical when producing intricate components with tight tolerances. For manufacturers in medical technology, micro-electronics, and optics, even the slightest deviation can render a product unusable.

The all-electric injection molding machine delivers superior repeatability and dimensional accuracy, thanks to its high-resolution servo systems. By enabling real-time control and stable processing conditions, these machines consistently produce parts with minimal variance—batch after batch.

At YIZUMI, our all-electric series integrates advanced control algorithms and rigid structural design, helping manufacturers achieve tight part tolerances with minimal cycle time variation.

Cleanroom Compliance: A Must-Have for Sensitive Applications

Many high-end applications—such as drug delivery devices, medical packaging, and semiconductor components—require production in cleanroom environments where airborne particles, oil mist, and other contaminants are strictly controlled.

Hydraulic machines, with their reliance on oil and risk of leakage, are less suited to these sensitive applications. The all-electric injection molding machine, on the other hand, is free from oil-based contamination risks, making it an ideal solution for cleanroom-class production.

In addition to eliminating contamination concerns, all-electric machines run quieter and produce less heat, helping maintain a stable and controlled cleanroom environment.

Electric Injection Molding Machine For Medical Industry

Key Advantages of All-Electric Injection Molding Machines

Investing in an all-electric injection molding machine offers a range of advantages beyond just precision and cleanliness:

1. Energy Efficiency

Electric servo motors operate only when needed and consume significantly less energy than constantly running hydraulic pumps. Energy savings of up to 50–70% can be achieved, making it a sustainable choice for high-volume production.

2. Fast Cycle Times

With instant response and acceleration capabilities, all-electric models drastically reduce cycle times, especially in applications with short shot volumes and fast mold movements.

3. Low Maintenance

Without hydraulic fluid systems, the risk of oil leaks, filter clogging, and pump failures is eliminated. This results in lower maintenance costs and less downtime.

4. Quiet Operation

Electric machines run much quieter than hydraulic ones, improving working conditions and reducing noise pollution in the production area.

5. Digital Process Control

Electric machines offer fine-tuned control over each phase of the molding process, including precise injection speeds, clamping force, and position monitoring. This level of automation improves consistency and reduces human error.

Injection Molding For LED Beads

Applications Across High-Precision Industries

The versatility and clean performance of the all-electric injection molding machine make it highly suitable for industries such as:

Medical Devices: Syringes, inhalers, and diagnostic components demand particle-free production and high dimensional accuracy.

Consumer Electronics: Connectors, camera components, and micro gears require micro-scale precision.

Automotive Sensors: Complex sensor housings and lightweight parts benefit from fast, precise molding.

Optics: Lenses and optical holders must be molded in ultra-clean conditions with zero tolerance for defects.

YIZUMI’s all-electric machines are engineered to meet these rigorous demands, offering tailored solutions for each industry’s unique needs.

YIZUMI’s Advanced All-Electric Series: Designed for Performance

At YIZUMI, we understand the growing importance of clean, efficient, and precise molding systems. Our all-electric injection molding machine lineup is the result of years of research, innovation, and close collaboration with global manufacturers.

FF Series Electric Injection Molding Machine

Key Features of YIZUMI All-Electric Machines:

Servo Motor Control: Independent servo motors for each axis deliver unmatched control and repeatability.

High-Speed Clamping Units: Improve productivity while ensuring mold protection.

Integrated Data Monitoring: Real-time analytics support process optimization and quality assurance.

Modular Design: Customizable machine configurations for various part sizes and applications.

Cleanroom-Ready Build: Designed to meet ISO Class 7–8 cleanroom standards (equivalent to Class 10,000–100,000 under FS 209E / FED-STD-209E), featuring smooth surfaces and minimal dust retention.

Our all-electric solutions are not just machines—they are production systems designed to meet global standards in medical, electronics, and high-end manufacturing sectors.

Choosing the Right All-Electric Solution

When evaluating an all-electric injection molding machine, consider the following factors:

Part Complexity and Tolerance Requirements

Cleanroom or Environmental Needs

Cycle Time Demands

Energy Efficiency Goals

Automation Compatibility

YIZUMI’s application engineering team works closely with customers to select and configure machines that match their production goals. We offer global support, turnkey solutions, and comprehensive training to ensure smooth integration into any manufacturing line.

Conclusion

The shift to all-electric injection molding machines represents more than just an upgrade in technology—it’s a strategic decision for manufacturers aiming to stay ahead in quality, sustainability, and regulatory compliance. These machines not only meet the growing demands for precision and cleanliness but also offer operational advantages that lead to long-term ROI.

As industries evolve toward smarter and cleaner production, investing in an all-electric solution is not just the right move—it’s the future of high-performance injection molding. For more information on YIZUMI’s all-electric series or to request a custom quote, contact us today! Discover how our technology can elevate your production capabilities.