Top 10 Benefits of Two-Platen Injection Molding Machines for High-Volume Production

Abstract:

Discover how YIZUMI two-platen injection molding machines offer energy-efficient, high-volume production advantages.

In the fast-paced world of modern manufacturing, especially in the production of large plastic components, choosing the right injection molding equipment can make or break your efficiency, quality, and energy use. For manufacturers aiming to scale up without compromising precision, two-platen injection molding machines?offer a transformative solution.

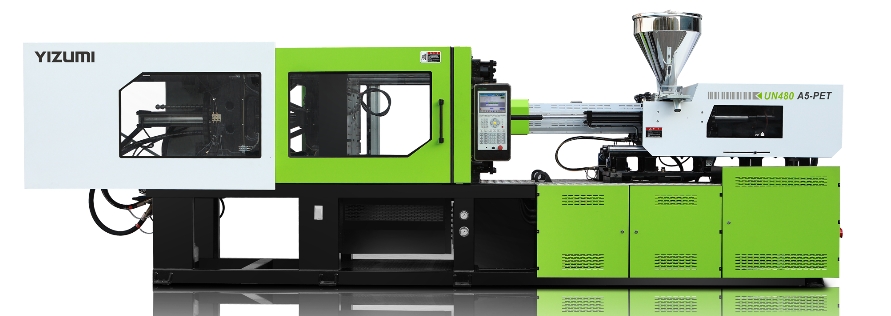

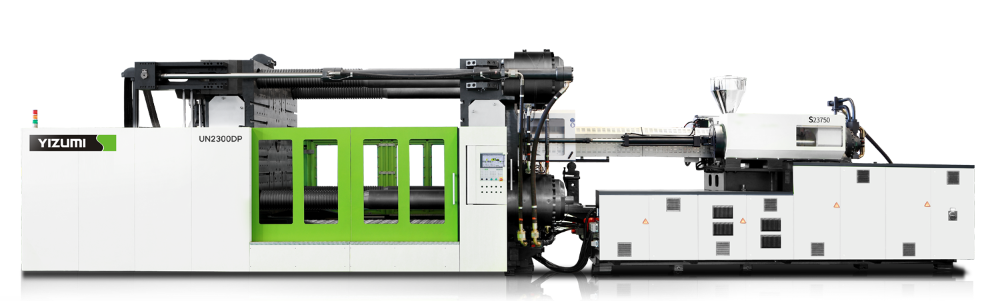

More specifically, the YIZUMI two-platen injection molding machine?represents the next generation of large-scale plastic part production solutions, combining space efficiency with unparalleled performance. This article explores the top 10 benefits of two-platen machines and how YIZUMI delivers unmatched value for high-volume applications.

1. Compact Footprint and Higher Productivity

Traditional toggle-based injection molding machines often require substantial floor space due to their complex linkage systems. In contrast, two-platen machines use a more direct and linear clamping system, significantly reducing machine length.

This compact design allows manufacturers to:

l Install more machines per square meter

l Reduce workshop rental and maintenance costs

l Increase productivity per unit area

For industries with space constraints, such as automotive and home appliance manufacturing, a two-platen system is often a smarter investment.

2. Energy-Efficient Injection Molding at Its Core

Two-platen machines are generally more energy-efficient?due to their reduced moving parts and optimized hydraulic systems. This is especially important in today's cost-sensitive and environmentally conscious production climate.

YIZUMI takes this further with our advanced Ecoservo drive technology, paired with piston variable pumps. These components ensure fast responses, minimal leakage, and tailored power configurations that cut down on energy waste.

3. Superior Mold Handling Capabilities

Another key advantage is the ability to handle extremely large and heavy molds. Two-platen machines support longer opening strokes and greater platen distances, enabling the molding of bulkier and more complex parts.

This makes them ideal for industries producing:

u Automotive bumpers and dashboards

u Trash bins and crates

u Appliance housings and structural panels

The YIZUMI two-platen injection molding machine?supports clamping forces from 550 to 4,000 tons—making it incredibly versatile for diverse industrial needs.

4. Enhanced Process Stability and Precision

Stability is crucial when dealing with high-cavity or high-tolerance molds. YIZUMI integrates ultrasonic digital displacement sensors?and high-rigidity carriage supports?into the DP Series, ensuring precision and repeatability.

This precision becomes even more important during long production runs, where even the slightest deviation could result in large-scale waste or product inconsistency.

5. Reduced Maintenance and Downtime

Because the two-platen system has fewer moving parts compared to three-platen systems, wear and tear is inherently lower.

YIZUMI goes a step further with features like:

? Automatic tie bar retraction?for easier mold installation and maintenance

? Impact-cushioning cylinders?that minimize mechanical stress

? Synchronous locking nut mechanisms?for reliable clamping

Less maintenance means reduced downtime and improved ROI over the lifespan of the machine.

6. Optimized Cycle Time for High-Volume Production

Cycle time is a critical KPI in high-volume injection molding. YIZUMI’s DP Series is designed with:

? Simultaneous mold opening and plasticizing

? Ejection and core pulling during parallel operations

These features work in tandem to shave seconds off each cycle, translating into thousands of additional parts produced monthly.

7. Modular and Flexible Configuration

Unlike fixed systems, YIZUMI's modular injection unit and drive system?allows for customization to match specific production needs. Whether you're working with foam, long glass fibers, carbon fiber composites, or standard plastics, you can tailor the DP Series to your requirements.

This flexibility also supports:

l Multi-material micro injection molding

l Injection compression molding (ICM)

l FoamPro microcellular foam technology

As a result, manufacturers are not boxed into a one-size-fits-all mold and can adapt to evolving product requirements.

8. Smart Control Systems for Seamless Operation

The DP Series is equipped with Austria’s KEBA control platform, a leader in industrial automation systems.

Key features include:

l 15” TFT color touchscreen with intuitive UI

l Graphical parameter setting and real-time process monitoring

l Online analysis with actual curve display

l Free programming for custom processes and special molds

l Expandable I/O ports for auxiliary equipment integration

With such robust control, even complex cycles become easier to execute and optimize—improving both operator efficiency and part quality.

9. Environmentally Responsible Manufacturing

Sustainability isn’t just a buzzword—it's a priority for forward-thinking manufacturers. YIZUMI’s DP Series machines support this mission by:

l Using energy-saving drive systems

l Reducing hydraulic oil leakage

l Optimizing cycle time to limit power consumption

Incorporating energy-efficient injection molding?into your operations not only saves on utilities but also positions your company as a green, responsible manufacturer.

10. Proven Reliability in Diverse Applications

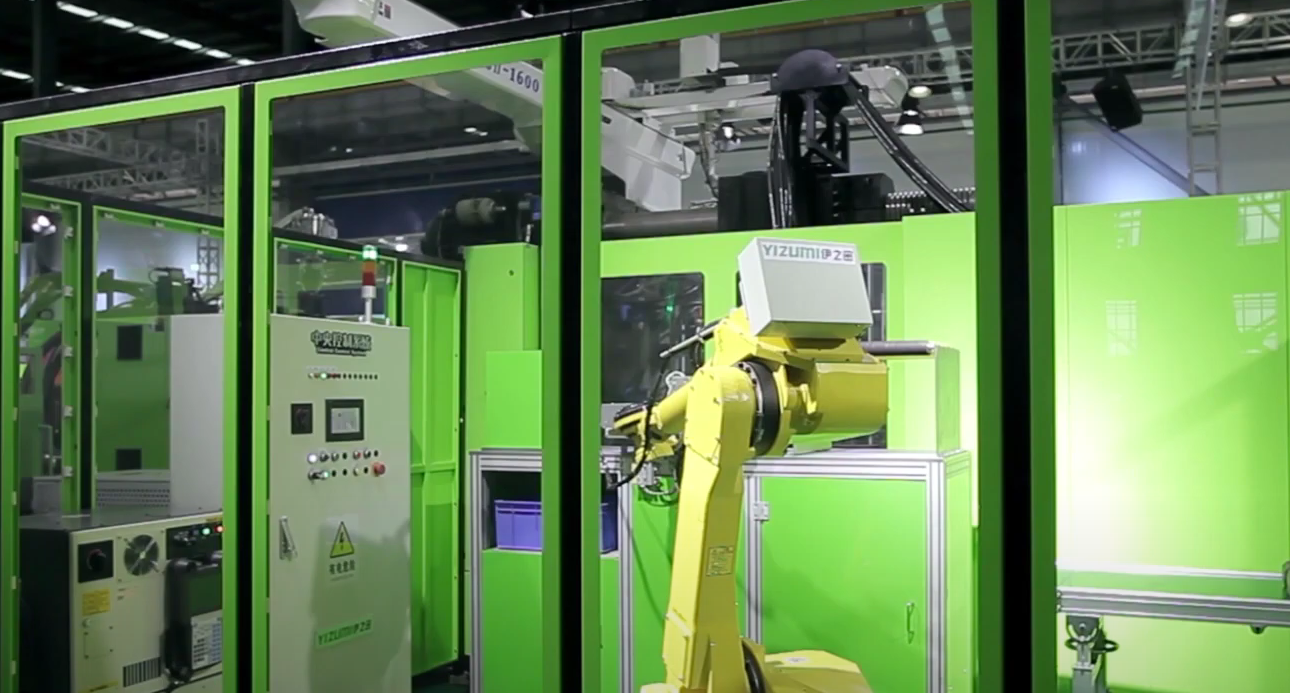

At YIZUMI, we’re not just selling machines—we’re delivering comprehensive forming equipment solutions. Our DP Series is currently being used in industries including:

l Automotive manufacturing

l White goods and household appliance production

l Logistics and packaging solutions

Our commitment to innovation, backed by our core technologies in rubber, die casting, and injection molding, ensures every machine we deliver supports your long-term business growth.

Why Choose YIZUMI Two-Platen Injection Molding Machines?

By combining advanced mechanical systems, efficient hydraulic and electric drives, and smart automation, we deliver one of the most sophisticated and reliable solutions in the large-scale plastic part production?market.

The DP Series Two-Platen Injection Molding Machine?offers unmatched benefits:

l Lower operational costs

l Higher output per square meter

l Customizable configurations

l Long-term durability

l Eco-conscious engineering

If your operation demands top-tier productivity, minimal energy waste, and precision, YIZUMI’s two-platen injection molding solution?is your strategic advantage.

Final Thoughts

From high-performance design to long-term sustainability, YIZUMI two-platen injection molding machines?represent a leap forward in modern manufacturing. Whether you’re optimizing floor space, cutting down energy usage, or scaling up your output, our machines are built to elevate your operations.

In a world demanding both speed and responsibility, our energy-efficient injection molding?technology ensures you're always ahead of the curve. For those looking to stay competitive in large-scale plastic part production, YIZUMI provides not just machines, but partnerships grounded in innovation and value.