Rubber Injection Molding for High-Voltage and Thermal-Resistant Energy Parts

Abstract:

As global energy systems become more advanced, the demand for high-performance components that can withstand extreme voltage and temperature conditions continues to grow. In this space, rubber injection molding has become a critical manufacturing process—especially for producing insulators, seals, bushings, and other thermal-resistant parts for energy transmission and distribution.

As global energy systems become more advanced, the demand for high-performance components that can withstand extreme voltage and temperature conditions continues to grow. In this space, rubber injection molding has become a critical manufacturing process—especially for producing insulators, seals, bushings, and other thermal-resistant parts for energy transmission and distribution.

By combining material science, precision engineering, and advanced machinery, rubber injection molding ensures durable, safe, and consistent parts that perform under the harshest environments found in the energy industry.

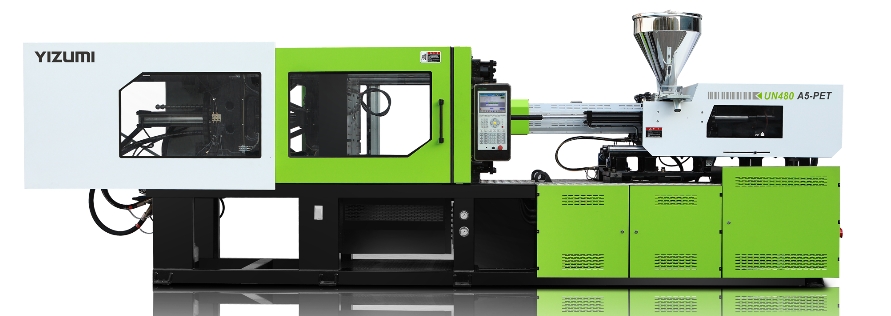

Rubber Injection Machine For Electric Insulators

The Role of Rubber Injection Molding in the Energy Sector

Rubber injection molding is especially suited for producing high-voltage insulation components and heat-resistant rubber parts used in substations, transformers, wind energy converters, and solar inverters. Unlike traditional rubber molding methods, injection molding ensures:

Precision and Consistency

Rubber injection molding machines deliver repeatable, flash-free parts with tight tolerances. This is essential when producing parts for 10 kV to 1000 kV systems, where even minor defects could compromise insulation integrity or system reliability.

Material Optimization

Energy components often require silicone, EPDM, or fluororubber materials for their dielectric properties and thermal endurance. The process enables the precise control of material flow, curing, and cooling for these specialized elastomers.

High Efficiency

Shorter cycle times, lower scrap rates, and automation-friendly setups make rubber injection molding ideal for volume production while keeping long-term costs manageable.

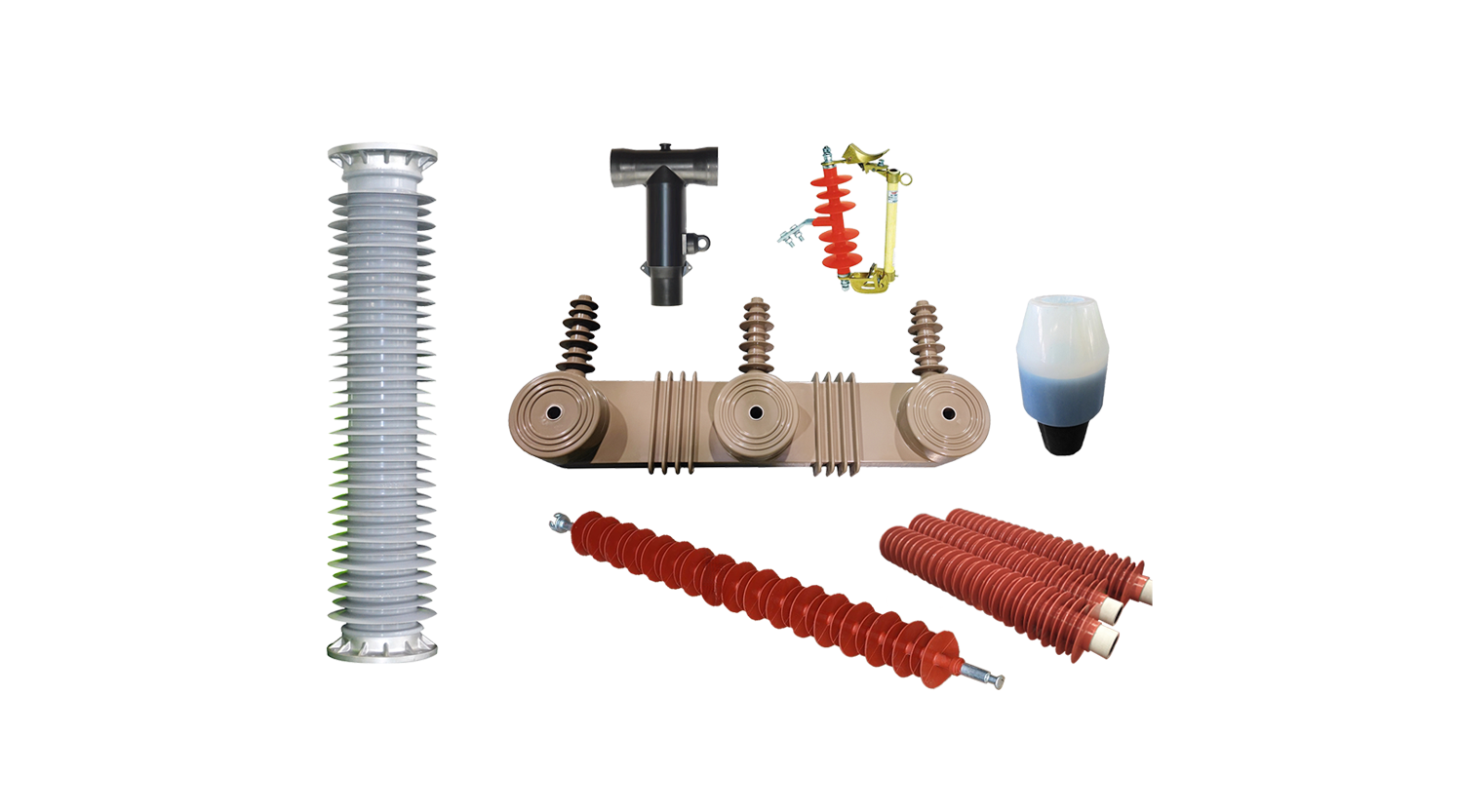

Rubber Injection Molding For Electrical Parts

Key Benefits of Rubber Injection Molding for Energy Applications

Thermal and Electrical Resistance

Rubber materials like silicone and EPDM, when molded through controlled injection processes, provide excellent thermal insulation and electrical resistance. These properties are crucial for parts used in switchgear, cable terminations, and transformer gaskets.

Complex Geometries with Minimal Flash

The high-precision mold sealing and clamping systems in rubber injection molding machinery allow for the production of complex geometries—such as high-voltage insulator boots and cable adapter caps—with minimal post-processing.

Reduced Risk of Material Defects

Advanced injection units avoid air entrapment and material scorch, common issues in traditional compression molding. This ensures the internal structure of molded parts is free from voids and inconsistencies.

Long-Term Durability

Whether exposed to high temperatures, UV radiation, or electrical stress, parts produced via rubber injection molding retain their physical and insulating properties over extended service periods.

Rubber Injection Molding Machinery For Electric Transformers

Common Applications in Energy Infrastructure

Rubber injection molding plays a critical role in manufacturing a wide range of components essential to power systems:

- High-Voltage Insulator Boots – Protective covers that prevent arc discharge and environmental contamination on energized components.

- Cable Grommets and Seals – Flexible sealing elements that maintain enclosure integrity and protect against moisture and dust.

- Thermal Barrier Gaskets – Used in power inverters and transformers to separate hot components and prevent thermal transfer.

- Bushing Interface Sleeves – Provide insulation between transformers and external conductors, ensuring safe and stable connections.

- Expansion Joints – Allow for movement caused by thermal cycling in electrical enclosures and outdoor systems.

How to Ensure Reliable Performance in Rubber Molded Energy Parts

To maximize performance and production efficiency, manufacturers must pay close attention to the following:

- Mold Design: Optimize parting lines, venting, and gating to reduce flash and improve material flow.

- Material Compatibility: Select rubber compounds that meet both the mechanical and electrical requirements of the application.

- Temperature Control: Ensure consistent barrel, mold, and stuffer temperatures to avoid scorching and ensure uniform curing.

- Quality Monitoring: Integrate process monitoring tools to detect pressure inconsistencies, cure anomalies, or dimensional drift in real time.

YIZUMI Custom-Built Rubber Injection Molding Systems for Energy Applications

The specialized molding machine for the energy industry from YIZUMI is designed to meet the exacting demands of modern energy infrastructure. Through years of development and close cooperation with industry professionals, YIZUMI offers a solution tailored for high-voltage and thermal-resistant rubber components.

Rubber Injection Molding System For Energy Industry

Core Features

Independent Intellectual Property: YIZUMI holds several patents for its energy-focused molding technologies, ensuring innovation and performance beyond generic platforms.

Dedicated Plasticizing and Injection Unit for Silicone: This specialized unit eliminates air entrapment and prevents compound degradation, delivering high-precision molded parts every cycle.

Safe and Efficient Silicone Stuffer: Designed for user convenience and operator safety, the silicone feeding system enhances reliability and ease of use.

High-Rigidity Clamping Unit: Maintains uniform clamping pressure even with large or complex molds, minimizing flash and mold distortion.

Flexible Clamping Configurations: Five clamping structure options are available to support various mold sizes and part requirements, improving adaptability and throughput.

Premium Hydraulic Components: Sourced from top global brands, the system ensures smooth operation, reduced energy usage, and extended service life.

By combining specialized features and robust design, YIZUMI’s rubber injection molding machine offers unmatched value for manufacturers producing energy components from 10 kV up to 1000 kV systems.

Conclusion

Rubber injection molding machinery stands at the heart of producing high-voltage, thermal-resistant energy parts with precision, efficiency, and reliability. By selecting the right rubber injection molding machine, optimizing mold design, and maintaining strict process controls, energy system manufacturers can deliver components that meet rigorous electrical and thermal requirements while controlling costs.

For energy industry leaders seeking turnkey, high-performance molding solutions, YIZUMI rubber injection molding offers unparalleled capabilities—transforming raw elastomers into mission-critical parts that power the world safely and sustainably. Please feel free to contact us for more information about the rubber injection molding machine for the energy industry!