Plastic Injection Molding Innovation & Creativity

Abstract:

The manufacturing world thrives on innovation, and plastic injection molding?stands as one of the most transformative technologies, offering versatility, efficiency, and precision. As industries demand more creative and customized solutions, injection molding technology?has evolved to meet these needs.

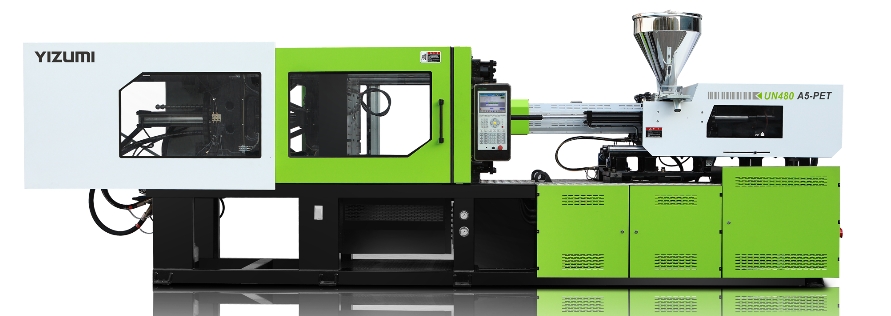

The manufacturing world thrives on innovation, and plastic injection molding?stands as one of the most transformative technologies, offering versatility, efficiency, and precision. As industries demand more creative and customized solutions, injection molding technology?has evolved to meet these needs. In this article, we will explore the innovations driving this field and how YIZUMI's VM Series Vertical Plastic Injection Molding Machine?is setting new benchmarks for creativity and efficiency.

The Role of Innovation in Plastic Injection Molding

Innovation is the backbone of progress in plastic injection molding. From reducing waste to enhancing product quality, advances in plastic injection molding machines?enable manufacturers to stay ahead in competitive markets. Key areas of innovation include:

· Energy Efficiency: Modern machines consume less power, reducing operational costs.

· Precision: Improved control systems ensure consistent and accurate production.

· Versatility: Machines now accommodate diverse materials and product designs.

YIZUMI leads this innovative journey with our VM Series, which embodies cutting-edge technology and exceptional performance.

Creativity in Injection Molding Technology

Creativity in manufacturing often lies in the ability to mold intricate designs and incorporate functional features. Plastic injection molding machines?have evolved to support:

· Complex Geometries: New technologies make it easier to mold intricate designs with high accuracy.

· Insert Molding: This process allows manufacturers to combine plastic with other materials, such as metal, in a single molding cycle.

· Sustainability: Advances enable the use of eco-friendly materials, supporting green initiatives.

The VM Series Vertical Plastic Injection Molding Machine?from YIZUMI is an excellent example of how technology meets creativity. Designed specifically for applications such as insert molding, the VM Series offers exceptional versatility, making it ideal for industries like automotive and consumer goods.

YIZUMI's VM Series: A Revolution in Vertical Injection Molding

The VM Series Vertical Plastic Injection Molding Machine?redefines efficiency and precision. Its innovative features make it a leader in plastic injection molding?technology:

High Precision

The VM Series employs proportional back-pressure control, ensuring accurate industrial controller operation and stable injection performance. This results in superior part quality, even for intricate designs.

Energy Efficiency

With our third-generation energy-saving servo technology, the VM Series reduces energy consumption by 30%-80% compared to conventional hydraulic machines. This not only cuts costs but also aligns with sustainability goals.

Optimized Plasticizing Screw

The plasticizing efficiency is increased by 10%-30%, improving the quality of plasticizing and color mixing. With four sets of standard barrel assembly, the machine can handle a wide range of applications.

Upgraded KEBA System

This advanced system offers expandable modules and real-time monitoring, ensuring operational safety and flexibility. The system's compatibility with modern communication interfaces enhances automation and process control.

How the VM Series Enhances Creativity

The VM Series opens new doors for innovation in plastic injection molding:

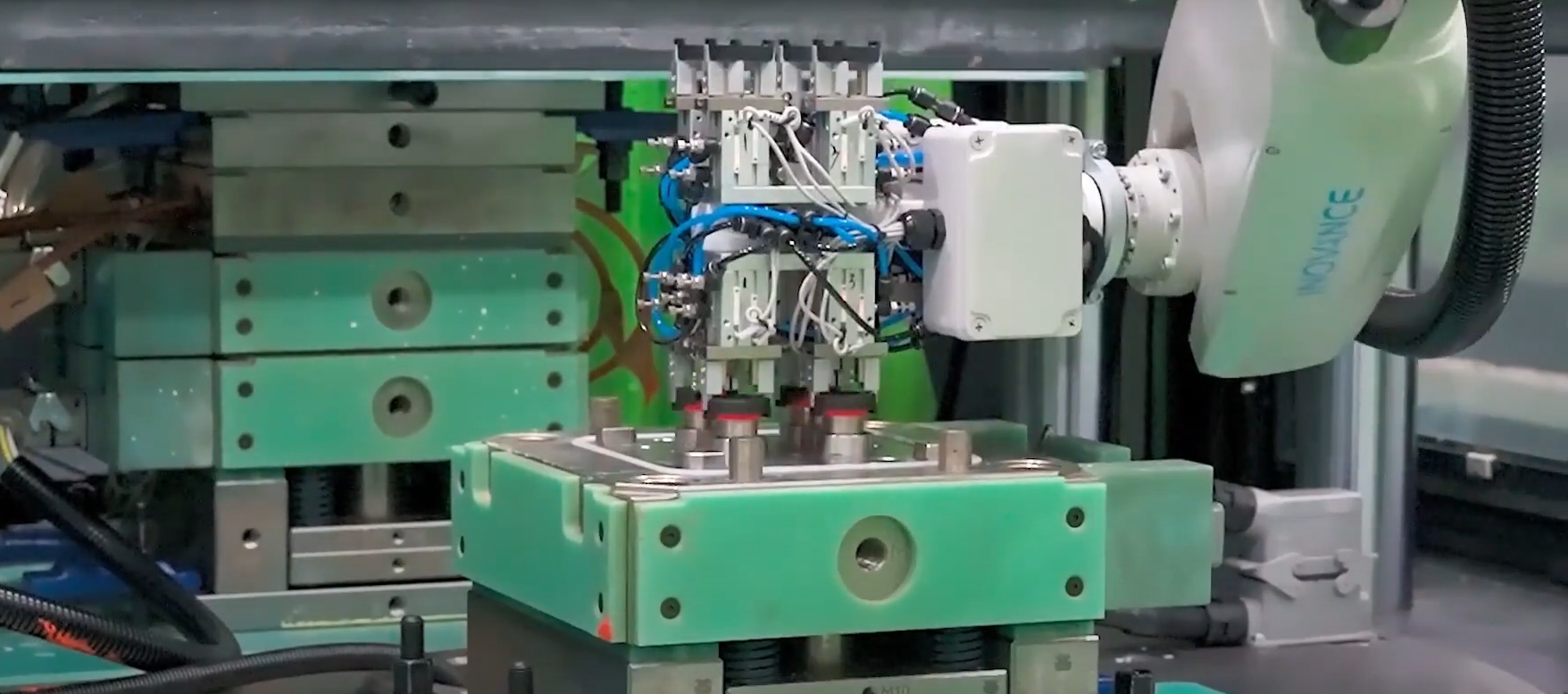

Insert Molding Made Easy

The vertical clamping mechanism is perfect for insert molding, allowing manufacturers to integrate plastic with other materials efficiently. This is particularly valuable in the automotive industry, where metal-plastic combinations are common.

Support for Diverse Applications

From auto parts to consumer goods, the VM Series adapts to various production needs. Its customizable modules ensure compatibility with complex product requirements.

Superior Stability

The closed-loop hydraulic oil temperature control, with an accuracy of ±0.5°C, enhances machine stability, ensuring consistent production quality.

Why Choose YIZUMI?

At YIZUMI, we understand the unique challenges that manufacturers face in today's rapidly evolving industrial landscape. From the need for high efficiency and precision to the growing demands for sustainability, the hurdles are significant. That's why we offer comprehensive, tailored solutions that address the full spectrum of manufacturing needs. With decades of industry expertise and a deep commitment to innovation, we provide cutting-edge technologies and unparalleled support to help our clients stay ahead of the curve.

Our core strengths lie in our advanced capabilities in rubber, die casting, and injection molding technologies. These specialized areas are the backbone of our product offerings, allowing us to deliver solutions that not only meet but exceed industry standards. Our team of experts continually pushes the boundaries of what's possible, integrating the latest advancements into every aspect of our designs and operations.

The VM Series, in particular, is a prime example of our commitment to excellence. More than just a machine, it represents a complete solution that empowers manufacturers to achieve greater efficiency, creativity, and sustainability. The VM Series combines state-of-the-art technology with intelligent design, offering unparalleled flexibility and precision. Whether you're looking to optimize your production process, reduce waste, or explore new product designs, the VM Series provides the tools you need to unlock your full potential.

At YIZUMI, we don't just provide equipment--we provide a partnership. Our focus is on helping you navigate the complexities of modern manufacturing, offering the support and expertise required to drive tangible results. With a focus on long-term growth and continuous improvement, we are proud to be a trusted partner for manufacturers across the globe.

Applications of the VM Series

The versatility of the VM Series makes it suitable for various industries:

· Automotive: Ideal for insert molding of components like connectors and brackets.

· Electronics: Produces precise and durable parts for consumer electronics.

· Medical Devices: Supports the creation of intricate and sterile components.

By leveraging the VM Series, manufacturers can achieve higher productivity and meet the evolving demands of their industries.

Innovation Meets Practicality

The innovations in injection molding technology?don't just stop at machine features—they extend to their practical impact:

· Reduced Waste: Precise control minimizes material waste, contributing to sustainability.

· Faster Production: High-speed operations ensure quicker turnaround times.

· Improved Quality: Consistent performance guarantees fewer defects and better products.

With YIZUMI's VM Series Vertical Plastic Injection Molding Machine, these benefits are a reality for manufacturers worldwide.

Conclusion

As the demand for complex and high-quality plastic products grows, plastic injection molding technology?must continue to innovate. YIZUMI's VM Series Vertical Plastic Injection Molding Machine?is a testament to what's possible when creativity and technology come together.

From precision and energy efficiency to versatility and sustainability, the VM Series empowers manufacturers to stay competitive while delivering exceptional products. If you're ready to redefine what's possible in plastic injection molding, YIZUMI is here to make it happen.