Injection Molding for Consumer: Meeting the Demands of High-Volume Production

Abstract:

Learn the best practices for maintaining injection molding equipment to improve efficiency, extend machine life, and enhance performance with YIZUMI molding machines.

Injection molding is a cornerstone of modern manufacturing, providing the efficiency and precision required to produce high-quality plastic parts at scale. However, to sustain consistent production output and reduce costly downtime, proper maintenance of injection molding equipment?is essential. Without a structured maintenance strategy, manufacturers risk decreased machine efficiency, increased defect rates, and unexpected breakdowns that can disrupt operations.

This guide explores the best practices for maintaining injection molding machines, ensuring optimal performance, extending equipment lifespan, and maximizing return on investment. Whether you are operating a high-volume production line or a specialized molding facility, following these strategies will help keep your machines running smoothly.

Establishing a Preventive Maintenance Schedule

One of the most effective ways to maintain injection molding equipment?is through preventive maintenance (PM). Instead of waiting for parts to fail, a structured PM program helps identify potential issues before they lead to machine downtime.

Key Preventive Maintenance Tasks

· Lubrication:?Regularly applying lubrication to moving parts reduces friction and prevents wear. Components such as tie bars, guide rails, and injection units should receive routine lubrication based on the manufacturer’s recommendations.

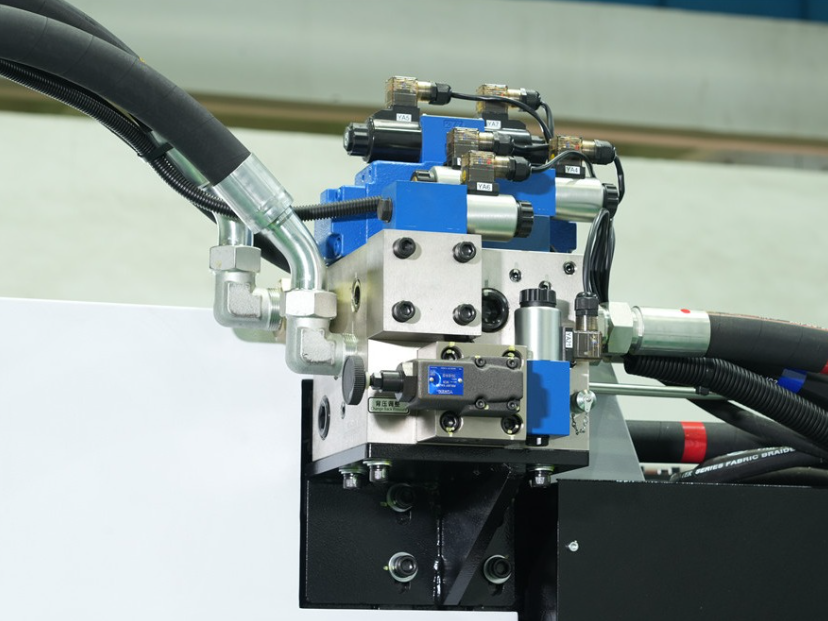

· Inspection of Hydraulic System:?Check hydraulic oil levels and quality. Dirty or degraded oil can cause increased wear on pumps and valves, leading to inefficiencies in machine operation.

· Cleaning and Cooling System Maintenance:?Cooling channels and heat exchangers should be cleaned periodically to prevent blockages that can reduce cooling efficiency and increase cycle times.

· Mold Maintenance:?Regularly inspect and clean molds to prevent flash, warping, or inconsistent part quality. Ensuring proper mold alignment is crucial to preventing defects.

By implementing these preventive maintenance?measures, manufacturers can improve production efficiency and extend the lifespan of their injection molding machines.

Monitoring Key Machine Parameters

A well-maintained injection molding machine?requires continuous monitoring of critical performance indicators. Keeping track of machine parameters allows operators to detect early warning signs of potential failures.

Essential Machine Parameters to Monitor:

· Clamp Force Stability:?Uneven clamping force can lead to part defects and excessive wear on the mold. Ensure that the machine’s clamping force is correctly calibrated and evenly distributed.

· Injection Pressure and Speed:?Variations in injection pressure or speed can indicate issues with the injection unit, such as a worn screw or barrel.

· Temperature Control:?Proper heating and cooling of the barrel, mold, and hydraulic system prevent inconsistent molding and material degradation.

· Cycle Time Consistency:?An increase in cycle times may indicate inefficiencies in the molding process, such as cooling system issues or component wear.

Leveraging real-time monitoring?and automated diagnostics?can further enhance maintenance efficiency, allowing manufacturers to make data-driven decisions to optimize performance.

Upgrading to Advanced Injection Molding Technology

While maintenance plays a vital role in keeping existing machines operational, investing in advanced molding machines?can significantly reduce maintenance requirements and improve production efficiency. Modern YIZUMI molding machines?are designed with cutting-edge technology to enhance performance, reliability, and energy efficiency.

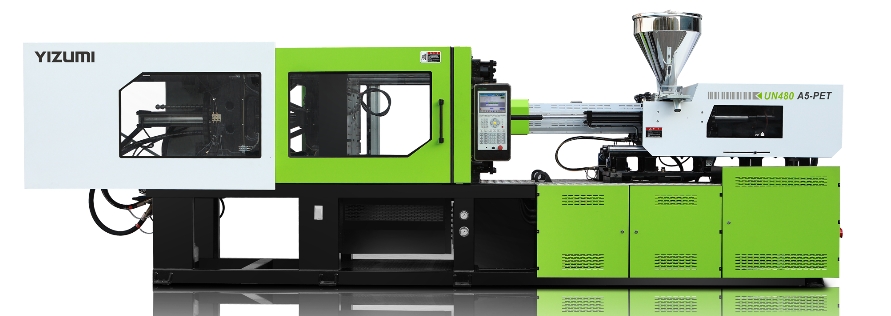

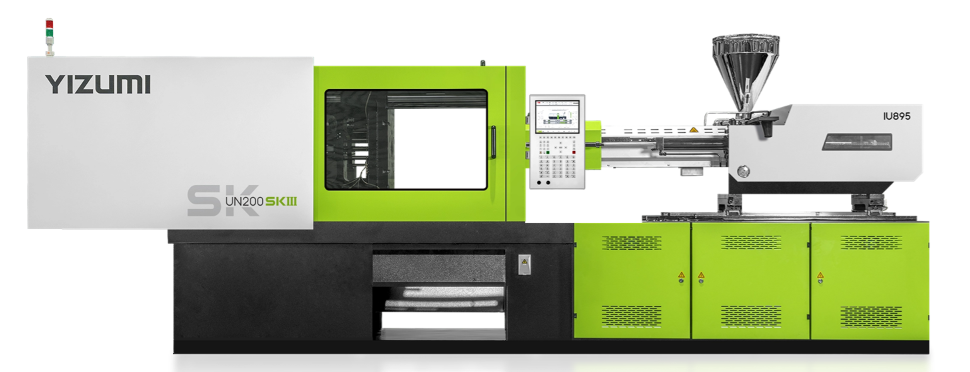

Why Choose YIZUMI’s SKⅢ Series General Purpose Injection Molding Machine?

At YIZUMI, we understand the challenges manufacturers face when maintaining injection molding equipment. That’s why we developed the SKⅢ Series General Purpose Injection Molding Machine, a next-generation solution designed for efficiency, energy savings, stability, and user-friendly operation.

Key Advantages of the SKⅢ Series:

Optimized Clamping Unit for Enhanced Durability

· The strong central support to the movable platen structure?minimizes deformation while achieving even force distribution.

· Lower clamping force requirements?reduce mold cavity deformation, improving molding accuracy and extending mold life.

· The highly rigid fixed platen and tail platen structure?ensures long-term stability and durability.

Advanced Injection Unit for Superior Precision

· The injection linear guide structure?reduces motion friction, increasing injection accuracy?and enhancing plasticizing efficiency.

· Linear carriage guide with dual-cylinder design?minimizes friction resistance, improving ease of operation and maintenance.

· The newly upgraded cooling system?optimizes heat dissipation, preventing overheating and ensuring consistent performance.

Industry-Leading Energy Efficiency

· Our fourth-generation energy-saving servo technology?reduces energy consumption while maintaining high-speed operation.

· The one-piece air duct technology?offers low noise and high-speed performance, improving the overall user experience.

· Optimized hydraulic design?minimizes oil pressure loss, increasing energy efficiency and reducing operational costs.

Smart Control System for Seamless Operation

· The upgraded KEBA system?provides real-time monitoring of machine sensors, ensuring safer and more precise operation.

· Expandable control modules?(AO, AI, DO, DI, TM) allow customization based on specific production needs.

· Supports multiple communication interfaces?(RS232/485, CANOPEN, Ethernet), ensuring seamless data integration for smart manufacturing.

By integrating YIZUMI’s SKⅢ Series?into your production line, you can reduce maintenance efforts, increase production stability, and achieve higher energy efficiency, all while maintaining superior part quality.

Best Practices for Extending the Life of Your Injection Molding Machine

Even with the latest technology, following best maintenance practices is essential to maximize the longevity of your injection molding machine.

Train Operators for Proper Machine Handling

A well-trained workforce can significantly impact machine performance and lifespan. Ensure that machine operators:

· Follow proper startup and shutdown procedures?to prevent component stress.

· Regularly inspect parts?for early signs of wear.

· Adhere to proper material handling protocols?to avoid contamination and reduce residue buildup in the barrel.

Use High-Quality Materials and Lubricants

Investing in high-quality raw materials and lubricants enhances the efficiency of injection molding equipment. Low-quality materials can cause premature wear, increasing maintenance frequency and costs.

Perform Periodic Calibration and Alignment

· Regularly check the clamping unit?to ensure proper force distribution.

· Inspect and align the injection unit?to maintain accurate injection pressure and speed.

· Verify sensor readings and control system accuracy?to prevent production errors.

Keep Detailed Maintenance Records

Documenting machine performance, maintenance schedules, and past repairs helps identify recurring issues and optimize future maintenance efforts. A well-maintained record system enables manufacturers to track long-term machine health?and predict component failures before they occur.

Conclusion

Proper maintenance of injection molding equipment?is essential for ensuring high productivity, reducing downtime, and extending machine lifespan. By implementing a preventive maintenance strategy, monitoring key machine parameters, and investing in advanced YIZUMI molding machines, manufacturers can optimize their production processes while lowering operational costs.

With the SKⅢ Series General Purpose Injection Molding Machine, we offer a cutting-edge solution?that enhances efficiency, energy savings, and operational stability. By incorporating YIZUMI molding machines?into your production line, you gain access to state-of-the-art technology, expert support, and an integrated molding solution that meets the evolving demands of modern manufacturing.

By prioritizing maintenance and leveraging high-performance injection molding machines, manufacturers can achieve consistent quality, improved cycle times, and long-term operational success.