How to Take Control of Your Production and Eliminate Long Lead Times

Abstract:

Be proactive and take control of your production by investing in your own production equipment to eliminate the long lead times and high minimum order quantities dictated by the manufacturing vendors.

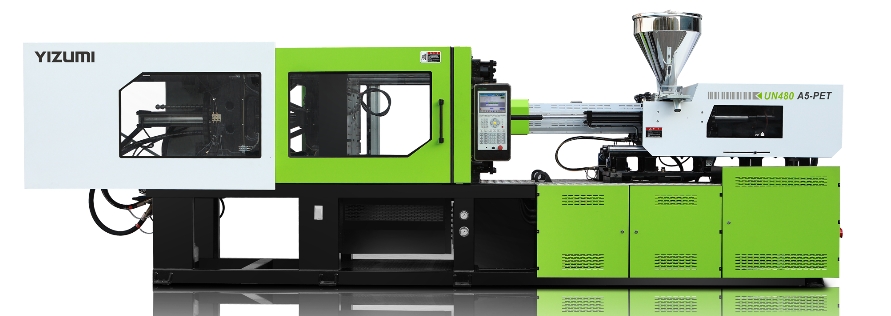

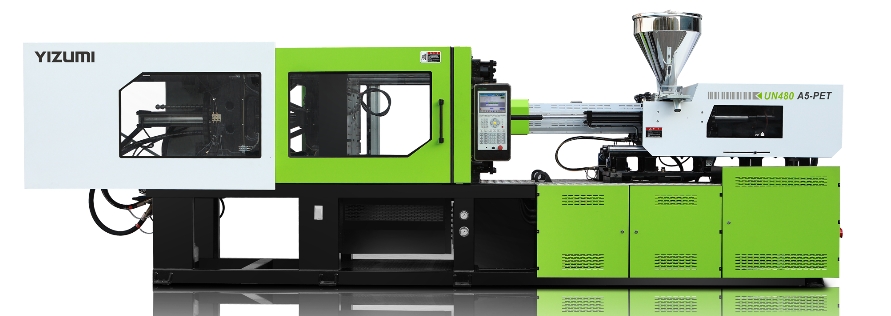

In today's competitive manufacturing landscape, controlling production and minimizing lead times are critical for success. Delays in production can lead to dissatisfied customers and lost revenue. By implementing effective strategies and leveraging advanced technologies, manufacturers can streamline their operations and improve productivity. One such technology is the YIZUMI PET Series Preform Injection Molding Machine, designed to enhance efficiency and precision in the production of PET preforms. This article will guide you through the steps to take control of your production and eliminate long lead times, focusing on the role of advanced injection molding systems.

Understanding Injection Molding Systems

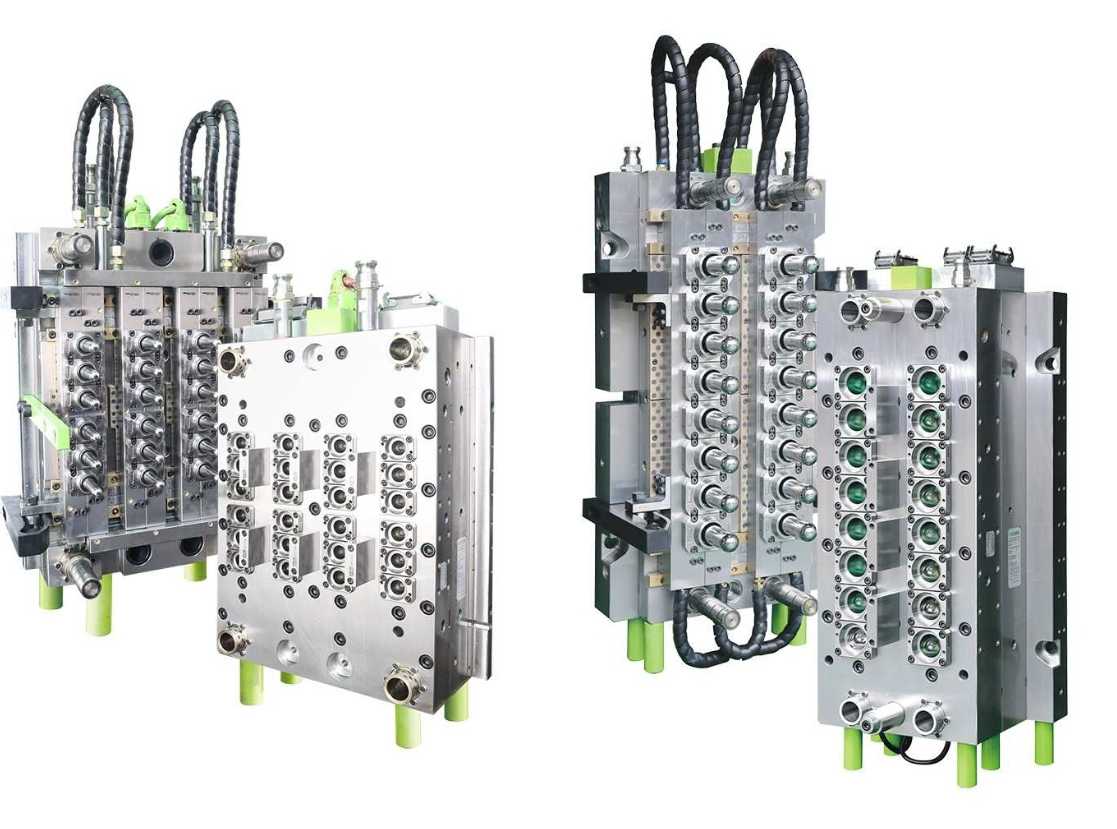

Injection molding systems play a crucial role in the landscape of modern manufacturing, serving as the backbone for the mass production of intricate and high-precision components. These systems are not just machines; they represent a sophisticated interplay between advanced injection molding machinery, innovative mold design, and strategic material selection. Each of these elements contributes to the overall effectiveness and efficiency of the injection molding process. The machinery itself is engineered to deliver precise control over temperature, pressure, and timing, ensuring that every part produced meets stringent quality standards. Complementing this is the importance of mold design, where careful consideration of geometry, cooling channels, and ejection mechanisms can greatly influence the outcome of the molding process. Additionally, the selection of the right materials—whether it be thermoplastics, thermosets, or specialty compounds—can further enhance the performance and durability of the final products. By optimizing these critical components—machinery, mold design, and materials—manufacturers can unlock significant improvements in productivity. This optimization leads to shorter production cycles, allowing for faster turnaround times and reduced lead times, which are essential in today's competitive market. As a result, businesses can respond more swiftly to customer demands, minimize downtime, and ultimately increase their overall profitability. In essence, the synergy of these elements within injection molding systems not only drives efficiency but also positions manufacturers for sustained success in an ever-evolving industry.

The YIZUMI PET Series, featuring advanced technology and superior performance, exemplifies how injection molding systems can revolutionize production. With clamping forces ranging from 1,200 to 6,500 kN, our machines excel in producing diverse preform types efficiently.

Streamlining Your Production Process

To effectively control your production, it's essential to streamline processes and eliminate inefficiencies. Here are several strategies to consider:

Optimize Machine Settings

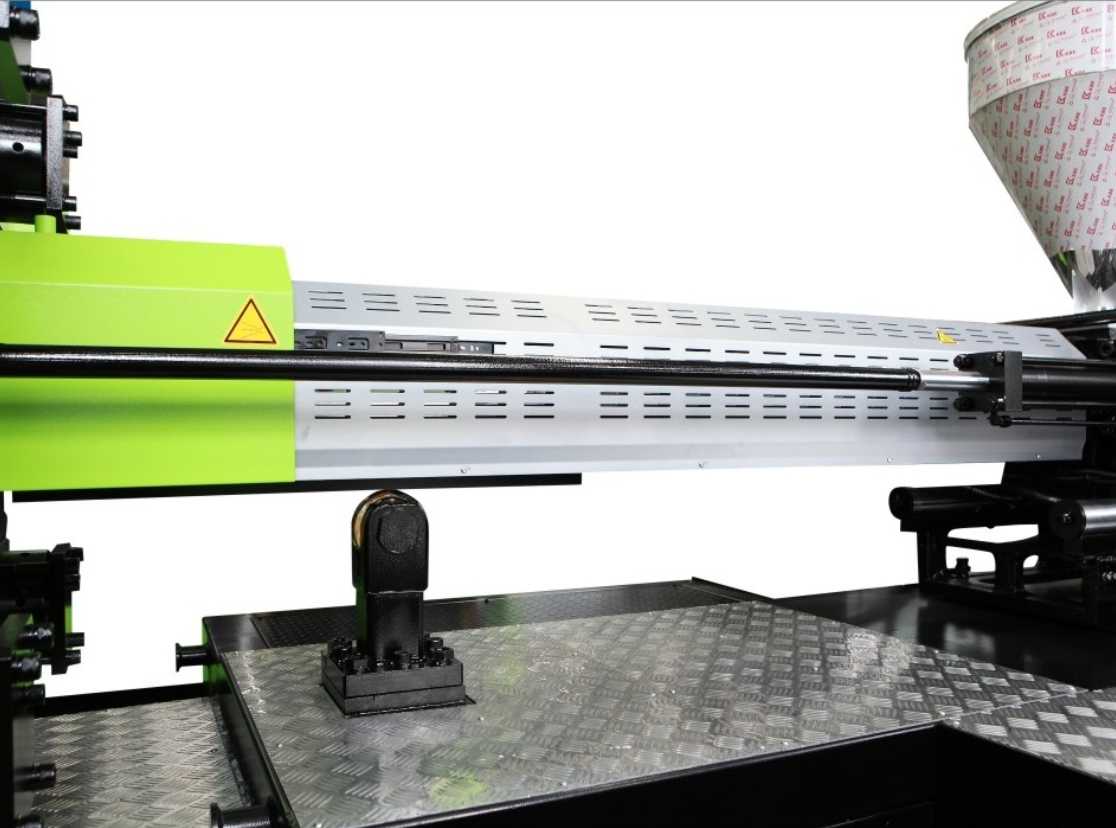

Every injection molding machinery requires specific settings to operate efficiently. Ensuring that your YIZUMI PET Series machine is properly calibrated can lead to enhanced plasticizing efficiency and improved output. Our advanced double carriage design allows for even force distribution, resulting in more consistent product quality and reduced cycle times.

Invest in High-Performance Equipment

Upgrading to modern injection molding systems like the YIZUMI PET Series can drastically enhance your production capabilities. Our machines feature a high-performance plasticizing system that increases productivity by up to 20% compared to conventional models. By investing in advanced equipment, you can achieve faster cycle times and higher quality outputs.

Implement Preventive Maintenance

Regular maintenance of your injection molding machinery is crucial to preventing unexpected downtimes. Develop a preventive maintenance schedule for your YIZUMI equipment to ensure optimal performance and longevity. By keeping your machinery in peak condition, you can avoid disruptions in production and maintain a steady output.

Utilize Data Analytics

Leverage data analytics to monitor your production processes in real-time. By analyzing data from your injection molding systems, you can identify bottlenecks and inefficiencies that contribute to long lead times. Implementing adjustments based on data insights can lead to more informed decision-making and streamlined operations.

Enhance Workforce Training

Ensuring that your operators are well-trained in using injection molding machinery can significantly impact production efficiency. Provide ongoing training for your team on best practices for operating the YIZUMI PET Series and understanding the intricacies of injection molding systems. A skilled workforce can better troubleshoot issues and maintain high productivity levels.

Addressing Common Challenges

Despite your best efforts, challenges may arise that can disrupt production. Here are some common issues faced by manufacturers and how to address them:

Material Variability

Variations in material properties can lead to inconsistent product quality. To combat this, we offer customized PET plasticizing components tailored to specific industry needs, such as cosmetics or food and beverage. By using optimized materials and processing techniques, you can enhance product uniformity and stability.

Mold Design and Maintenance

A well-designed mold is essential for successful injection molding. The YIZUMI PET Series includes features like a T-slot and mold clamp hole combination, which facilitate easier mold loading and unloading. Regularly inspect and maintain molds to prevent defects such as flash or short shots, ensuring a smooth production process.

Cooling Time Optimization

Inefficient cooling can lead to longer cycle times and increased lead times. The YIZUMI PET Series incorporates advanced cooling systems that help manage mold temperatures effectively, reducing cycle times and improving overall productivity.

Settings Examples for the PET Series Injection Molding Machine

To achieve optimal results, consider the following settings for the YIZUMI PET Series:

Injection Speed: Adjust the injection speed based on the specific material and mold design. The optimized injection unit of our PET Series provides improved rigidity and stability, allowing for precise control over injection speed.

Temperature Control: Utilize the high-performance plasticizing system to maintain consistent temperature settings. This control is vital for producing high-quality preforms, especially when working with specialized materials.

Pressure Settings: Monitor and adjust pressure settings to ensure that clamping forces are balanced. The Double Center Press Platen design minimizes platen deformation, resulting in fewer defects and improved quality.

Conclusion

Taking control of your production and eliminating long lead times requires a multifaceted approach that includes optimizing injection molding systems, investing in advanced machinery like the YIZUMI PET Series, and implementing effective operational strategies. By streamlining processes, enhancing workforce training, and leveraging data analytics, manufacturers can significantly improve productivity and maintain a competitive edge in the market.

At YIZUMI, we are committed to providing innovative injection molding solutions that meet the diverse needs of our customers. Our?PET Series?is designed to enhance plasticizing efficiency and deliver superior performance, making it the ideal choice for manufacturers looking to improve their production capabilities. Embrace these strategies and watch your production transform as you reduce lead times and increase overall efficiency. If you want to experience more about the charm of molding equipment, please visit YIZUMI's website!