How Advanced Injection Molding is Transforming Everyday Products

Abstract:

Explore how advanced servo injection molding machines are revolutionizing manufacturing. Discover the benefits of YIZUMI’s A5-EU Series for precision, efficiency, and sustainability.

The Silent Force Behind Everyday Products

From the car you drive to the packaging that protects your food, injection molding machines?play an essential role in modern life. This manufacturing technology allows industries to create high-quality, durable, and cost-effective products at scale. However, as global demands for efficiency, precision, and sustainability?increase, traditional molding methods are being replaced by advanced servo injection molding machines.

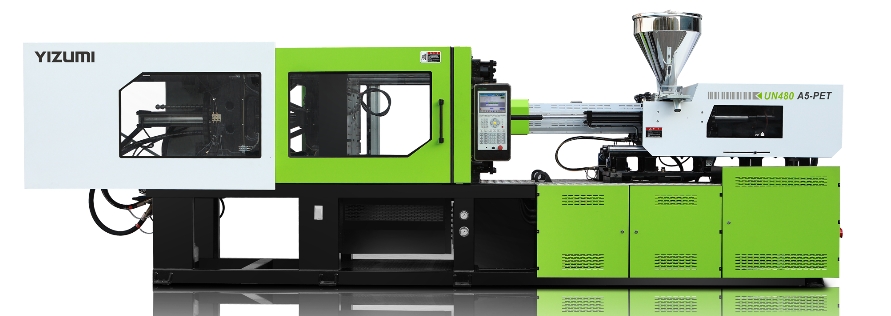

Among the industry leaders, YIZUMI’s A5-EU Series?stands out as a solution that enhances production while reducing waste and energy consumption. But how exactly is this transformation happening, and why should manufacturers consider upgrading to servo injection molding machines? Let’s explore.

How Injection Molding Has Transformed Manufacturing

1. Speed and Efficiency in Production

Traditional molding techniques often require long production cycles, significant energy usage, and frequent maintenance. Servo injection molding machines?address these inefficiencies by optimizing motor performance, ensuring faster cycles with precise control over pressure, temperature, and speed.

2. Cost Reduction Through Energy Savings

One of the most significant advancements in servo-driven technology is energy efficiency. Unlike conventional hydraulic systems, which run continuously, servo motors adjust power usage dynamically, reducing energy consumption by 30%-80%. This leads to lower electricity bills, decreased operational costs, and a reduced carbon footprint.

3. Improved Product Quality

Defects such as warping, shrinkage, and inconsistent material distribution have long been challenges in injection molding. With servo injection molding machines, manufacturers benefit from better material flow control, leading to fewer defects and improved consistency across batches. This is especially crucial in industries such as automotive, medical devices, and electronics, where precision is paramount.

Where Servo Injection Molding Machines Make an Impact

1. Automotive Industry: Strength and Durability

Modern vehicles rely heavily on injection-molded components, from engine covers to dashboard panels. The automotive sector demands high-strength, lightweight materials, and servo injection molding machines?provide the precision necessary to manufacture complex, durable parts with minimal waste.

2. Medical Industry: Precision in Every Component

Medical equipment such as syringes, prosthetic components, and surgical tools?must meet stringent hygiene and quality standards. Servo-controlled injection molding machines?allow for cleanroom-compatible production, ensuring reliability and safety.

3. Electronics and Consumer Goods: Aesthetic and Functional Excellence

From smartphone casings to home appliances, manufacturers require high-speed, high-precision molding?to maintain consistency and enhance product durability. Servo-driven technology provides the control and flexibility?needed to meet the fast-evolving consumer market.

YIZUMI's A5-EU Series: A Game-Changer in Injection Molding

At YIZUMI, we understand that manufacturers need more than just a machine—they need a complete solution?that enhances production while reducing costs and environmental impact. Our A5-EU Series High-end Servo Injection Molding Machine?is designed to meet these needs through advanced technology and superior engineering.

1. Clamping Unit: Strength and Stability

l European-style T-slot platen design?increases durability and ensures higher repeatability of clamping force.

l Highly rigid frame?minimizes deformation, providing long-term stability.

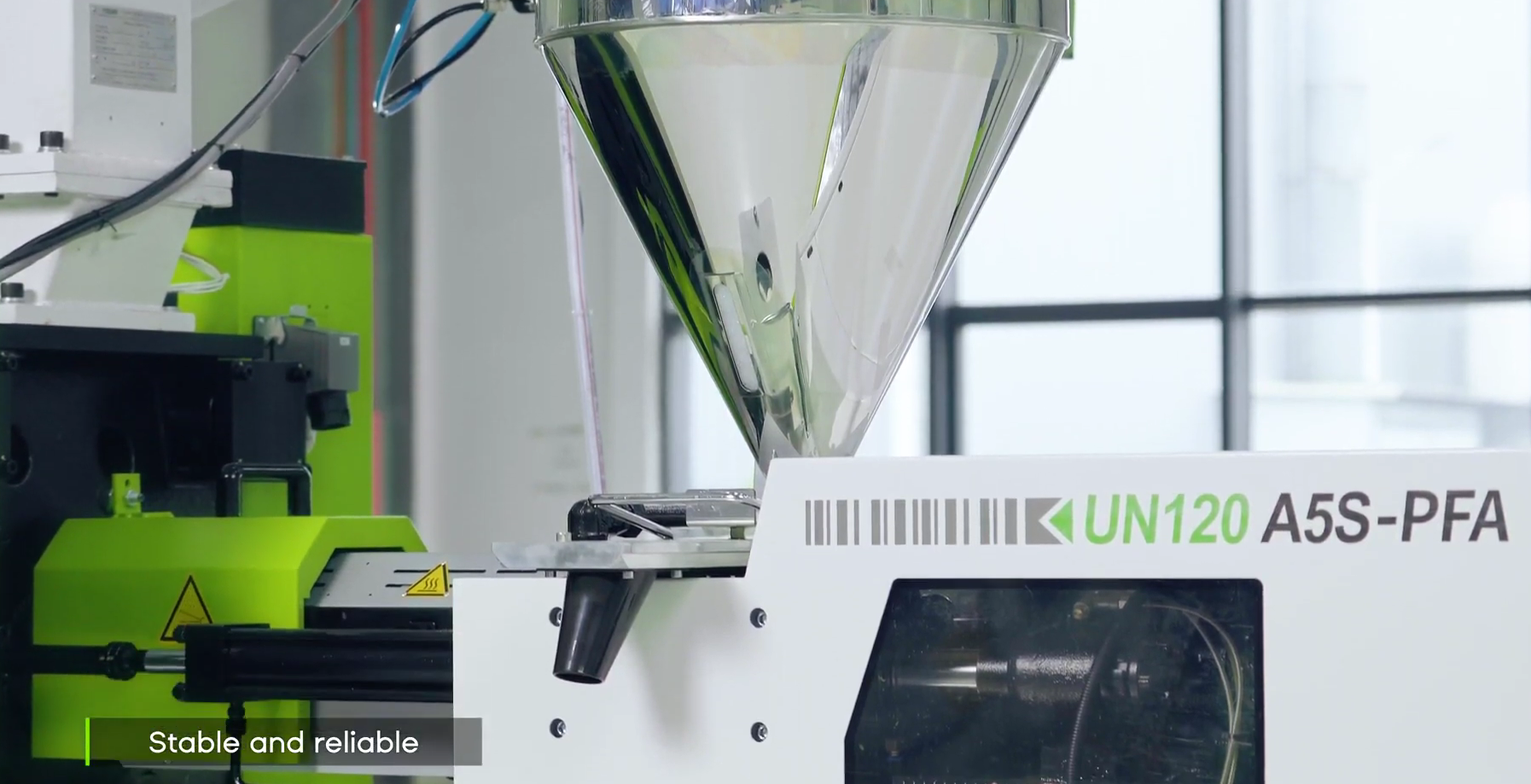

2. Injection Unit: Precision at Its Core

l Integrated linear guide rail support?reduces friction, leading to smoother operation and enhanced repeatability.

l Double-cylinder injection system?ensures consistent material flow, reducing defects and improving precision.

3. Next-Generation Servo Technology: Energy-Saving and Reliable

l The third-generation servo system optimizes motor efficiency, reducing energy consumption by 30%-80%?compared to traditional machines.

l Improved internal structure, magnetic steel selection, and drive software?enhance stability, durability, and noise reduction.

4. User-Friendly Control System

l Equipped with Austria’s KEBA control system, offering intuitive operation and faster processing speed.

l 10-inch TFT true-color touchscreen?enhances usability.

l USB-compatible mold data storage, making operation seamless and maintenance-friendly.

Why Manufacturers Are Choosing YIZUMI's Servo Injection Molding Machines

1. Reduced Energy and Material Waste

With servo injection molding technology, manufacturers can lower production costs without sacrificing quality. Energy savings combined with reduced material waste make it a sustainable choice?for businesses looking to optimize efficiency.

2. Higher Production Output with Lower Downtime

The precision and reliability of servo-driven systems?mean fewer breakdowns and maintenance issues. Manufacturers can achieve higher production targets?without the risk of unexpected machine failures.

3. Competitive Edge in a Fast-Paced Industry

With global markets evolving rapidly, manufacturers who adopt cutting-edge servo injection molding machines?can stay ahead of competitors by delivering high-quality products at faster speeds and lower costs.

FAQs About Servo Injection Molding Machines

Q1: How does a servo injection molding machine differ from a traditional hydraulic machine?

Traditional hydraulic machines run continuously, consuming large amounts of energy. In contrast, servo injection molding machines?adjust power usage dynamically, significantly reducing energy consumption and operational costs.

Q2: What industries benefit most from servo injection molding?

Industries such as automotive, medical, electronics, and consumer goods?benefit from the precision, energy efficiency, and reduced waste?provided by servo-driven machines.

Q3: How does YIZUMI’s A5-EU Series improve efficiency?

The A5-EU Series?integrates a high-rigidity clamping unit, precision injection system, and energy-saving servo technology, optimizing production speed, accuracy, and cost-effectiveness.

Q4: Can YIZUMI’s injection molding machines integrate with automation?

Yes! Our A5-EU Series?supports automation compatibility, including temperature control, robotic handling, and data integration?for streamlined manufacturing processes.

Q5: What are the long-term benefits of upgrading to servo injection molding technology?

Upgrading to a servo injection molding machine?means lower operational costs, increased production efficiency, enhanced product quality, and a reduced environmental footprint.

A Smarter Future for Manufacturing

As industries demand greater efficiency, sustainability, and precision, servo injection molding machines?are transforming how products are designed and manufactured. With energy savings, improved cycle times, and enhanced product quality, YIZUMI’s A5-EU Series?offers a complete molding solution for manufacturers looking to stay competitive in an evolving market.

By investing in cutting-edge servo injection molding technology, manufacturers can ensure cost-effective production, reduced environmental impact, and higher-quality products—shaping the future of manufacturing one injection at a time. Explore YIZUMI's servo injection molding technology today!