Mixing-free and drying-free DCIM solution: Integrated digital solution demonstration

Abstract:

At YIZUMI's production workshop, there is an automated production line for safety door roller. The entire production process is carried out in automated operations, from raw materials feeding to injection molding, automatic conveying and embedding of bearing inserts, in-mold monitoring, automatic product picking up, packing and placing, warehousing, etc. The rollers produced are used for injection molding machine assembly to achieve self-sufficiency, eliminating the need for external procurement.

At YIZUMI’s production workshop, there is an automated production line for safety door roller. The entire production process is carried out in automated operations, from raw materials feeding to injection molding, automatic conveying and embedding of bearing inserts, in-mold monitoring, automatic product picking up, packing and placing, warehousing, etc. The rollers produced are used for injection molding machine assembly to achieve self-sufficiency, eliminating the need for external procurement.

This is YIZUMI’s new integrated solution for automated roller production. The equipment production system includes raw materials, molds, new processes, integrated control of peripheral devices, injection molding machine, automation units, industrial interconnection, and other technologies that form the entire plastic processing ecology.

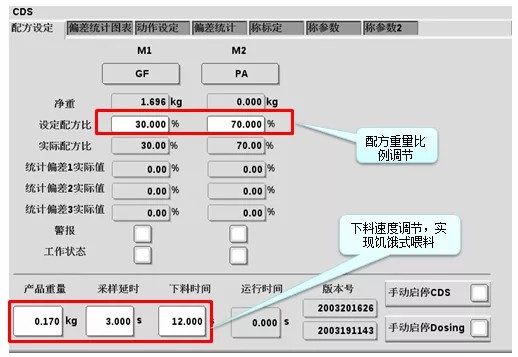

Loaded with the CMS management system developed by YIZUMI, the controller of the injection molding machine controls the peripheral auxiliary devices and metering equipment in an integrated manner. The process parameters can be uploaded to the cloud at the same time for remote management.

As a benchmark project that embodies the integration capacity of YIZUMI system, the solution is upgraded with the mix-free pelletizing, drying-free DCIM programs. In the injection molding process, the PA6 and glass fiber are dosed and mixed in proportion. Moisture and gas in the plastics are fully extracted to achieve a pelletizing-free and drying-free result. The solution is a proven approach toward the high performance of production and products.

Less process steps: Eliminate traditionalprocess steps / Green production mode

Equipped with an exhaust gas recovery port, a vacuum device, degassing plasticizing system for plastic heating, and a connector for degassing plasticizing system and air extractor, the injection molding solution integrates the “Direct Compounding Injection Molding” and “Drying-free Injection Molding.” During the operation, the injection molding machine heats the plasticized plastic melt using the degassing plasticizing system and conveys the plastic melt to the degassing position. The air extractor will evacuate the moisture and exhaust gas in the plastic melt from the exhaust outlet and discharge it through the exhaust gas recovery port into the designated device for centralized treatment.

Drying-free: Traditional equipment needs to go through the following three major steps to produce engineering plastics: dehumidification→feeding→injection. This molding solution only needs to undergo: raw material feeding → injection molding, eliminating the drying procedure required in a traditional injection molding machine production to achieve energy conservation, emission reduction, and environmental protection.

Pelletizing-free: The DCIM (Direct Compounding Injection Molding) system adds two or more sets of metering devices to the equipment to provide real-time measuring of the materials. The materials are fed into the hopper in set proportion under closed-loop control. The dosing is adjusted in real-time. The materials are mixed in the injection molding screw and directly injected into the mold without the step for material pelletizing.

Function upgrade: The new molding equipmentimproves the overall performance of materials

Newly designed special plasticizing system: Focusing on low shear mixing and uniform dispersion.

Add “Isochoric Flow” wavy structure based on the degassing screw to achieve low shear mixing throughout the injection molding process and ensure that the glass fiber completes injection molding under low shear strength. Compared with the traditional injection molding, it eliminates the pelletizing process to save energy and avoid second shearing on materials during pelletizing. For reinforced composite materials such as fiberglass, second shearing could result in a very high loss rate. This technology ensures the length of the fiberglass in the product to the greatest extent and maximizes the overall performance of the composite materials. In the meantime, as it allows flexible dosing adjustment and on-demand production, the system offers a great advantage in energy saving, lightweight, and plastic recycling rate.

Bearing customer value in mind, YIZUMI has been making great efforts to offer overall solutions for injection molding automation and work closely with customers to go through their production processes. The pelletizing-free, mixing-free and drying-free DCIM solutions overcome the shortcomings of production with traditional equipment, optimize the production process, and integrate several processes to achieve energy conservation and emission reduction while allowing recipe optimization and flexible recipe adjustment for optimal production results.