Thixomolding Milestone: YIZUMI Delivers Innovative 6600T Machine

Abstract:

YIZUMI launches the UN6600MGⅡ?Plus Thixomolding machine, revolutionizing magnesium alloy molding for lightweight EVs, aircraft, and robotics production.

YIZUMI has successfully delivered the UN6600MGⅡ?Plus Thixomolding machine at a critical point in global lightweight manufacturing competition. This breakthrough shatters the existing process limitations of semi-solid molding technology for magnesium alloys, from pioneering technology to end-to-end research and production services. YIZUMI propels the magnesium alloy industry toward scalable, high-quality development, accelerating its application in EVs, low-altitude economy, humanoid robots, and other sectors, reshaping the industry landscape and injecting powerful momentum in global lightweight manufacturing.

On July 16th, YIZUMI has successfully delivered the UN6600MGⅡ?Plus Thixomolding Machine to Sinyuan ZM at China Diecasting on-site, alongside the launch of an end-to-end "Semi-Solid Magnesium Alloy Research and Production Service". The machine not only redefines the global technological frontier of die casting equipment, but it also delivers a dual-driver "Technology + Service" model, offering turnkey solutions for large-scale production of integrated magnesium alloy parts. This advancement propels YIZUMI from "follower" to "leader" in the large magnesium alloy parts production.

01. The Rise of Magnesium Alloy in the Global Lightweighting Race

Under the goal of carbon neutrality, lightweight manufacturing has emerged as a global industrial priority. Magnesium alloy, currently the lightest commercially available green structural metal, has immense application potential. However, despite its advantages—lightweight, high strength, cost-effectiveness, and environmental benefits—its widespread adoption will be limited by technological barriers and cost. High-value magnesium alloy products account for less than 30% of the market, and total vehicle usage is less than 5 kg per unit, indicating that advances in high-end deep processing and material technology are still needed.[1]

Traditional magnesium alloy casting faces severe bottlenecks, including low material and yield efficiency, environmental and cost issues related to SF6 protective gases, molding limitations caused by dimensional accuracy and complex structure, short mold life, and poor human-machine integration. These challenges have significantly constrained the scalable industry growth of magnesium alloys.

02. Four Major Technological Innovations Solve Magnesium Alloy Molding Challenges

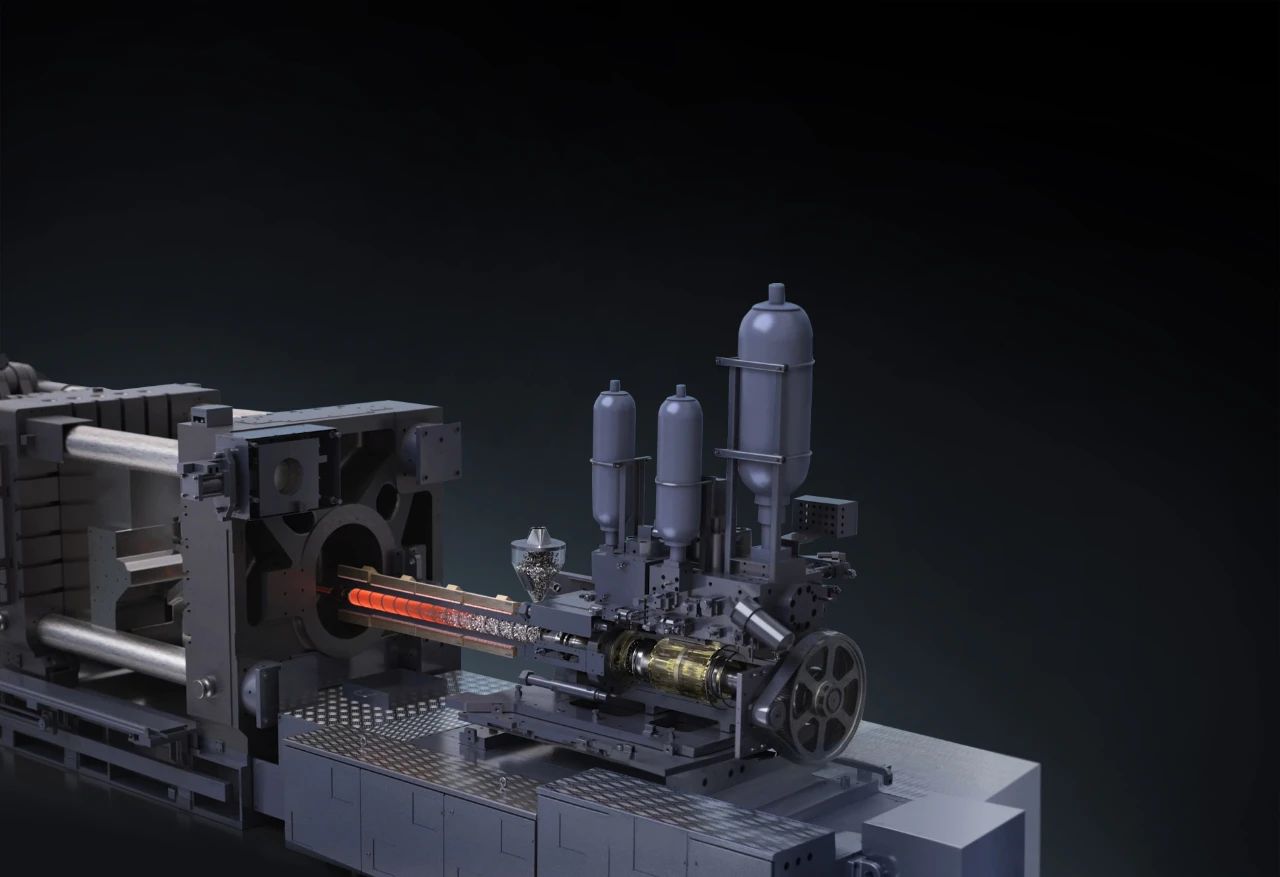

YIZUMI has been continually innovating for 16 years, beginning with China's first Thixomolding machine in 2009 and leading related industry standards. With its profound technical expertise, the new Thixomolding machines integrates four core features: Turbo injection system, Eco energy-saving melting technology, Multi-Hot Runner multi-point hot runner technology, and THIXO-Core precision and intelligent control technology. These innovations propel YIZUMI to the forefront of the industry in terms of locking force, injection capability, melt supply, and precision control, overcoming many traditional process challenges.

The newly delivered UN6600MGⅡ?Plus Thixomolding Machine makes four major advances:

1. Enhanced Melt Supply: By employing dual feeders and injection units, the effective maximum injection capacity is increased from 15 kg to 38 kg, making it ideal for large integrated magnesium alloy parts.

2. Boosted Injection Pressure: Ultra-high injection pressures ensure the internal compactness of large parts, overcoming shrinkage weaknesses in traditional processes.

3. Revolutionized Production Efficiency: Shorter cycle times and 5 million shot experiences of mold closing results in lower mold closing costs, improved equipment stability, and significantly increased throughput.

4. Optimized Material Utilization: Multi-point hot runner technology reduces casting scrap by 30%, shortens flow distance by over 500 mm, and ensures more uniform mold cavity pressure and temperature distribution, resulting in uniform and dense internal casting quality while revolutionizing the traditional excess gating waste.

03. Comprehensive Research-Production Service Empowers Efficient Industry Application

To address the complexity and high trial-and-error costs of semi-solid molding technology, YIZUMI has launched an innovative "One-Stop Rapid Research-Production Service for Magnesium Alloy Products".

This service covers six core stages:

- Semi-solid sample preparation

- Material performance testing and data verification

- Product modeling and 3D adjustment

- Mechanical and process simulations

- Mold design and manufacturing

- Trial-out and sample delivery

This service increases the efficiency of R&D for complex, large parts by more than 50%. It also breaks through the sub-15% IUR (industry-university-research) conversion rate and reduces R&D cycles by more than 50%.

Additionally, YIZUMI's "Yi+ Semi-Solid On-Site Butler Service" deploys an after-sales team to customer production locations to provide commissioning, trial-out support, practical training, headquarters expertise consulting, and standardized delivery packages, ensuring full lifecycle support. It enables customers to overcome mass production challenges and achieve efficient and stable production, contributing to the robust development of magnesium alloy lightweight manufacturing.

04. Large Scale Production Targets Million-Ton Applications

China's magnesium alloy industry is rapidly expanding, from 34 billion CNY in 2020 to a target of 120 billion CNY by 2030. With raw material prices stabilizing at low levels and mature technology and service systems, magnesium alloy applications are experiencing rapid expansion. Magnesium utilization per EV continues to rise, and YIZUMI Thixomolding solutions have been validated in mass production by companies like Sinyuan ZM. Looking ahead, the company's focus will shift to large magnesium alloy parts for EVs and low-altitude aircraft.

Leveraging its deep technological expertise, strong end-to-end research-production service capability, and precise industry insight, YIZUMI is leading the magnesium alloy industry beyond constraints, ushering in a new era of scaled, high-quality growth and heralding the rise of integrated magnesium alloy molding.