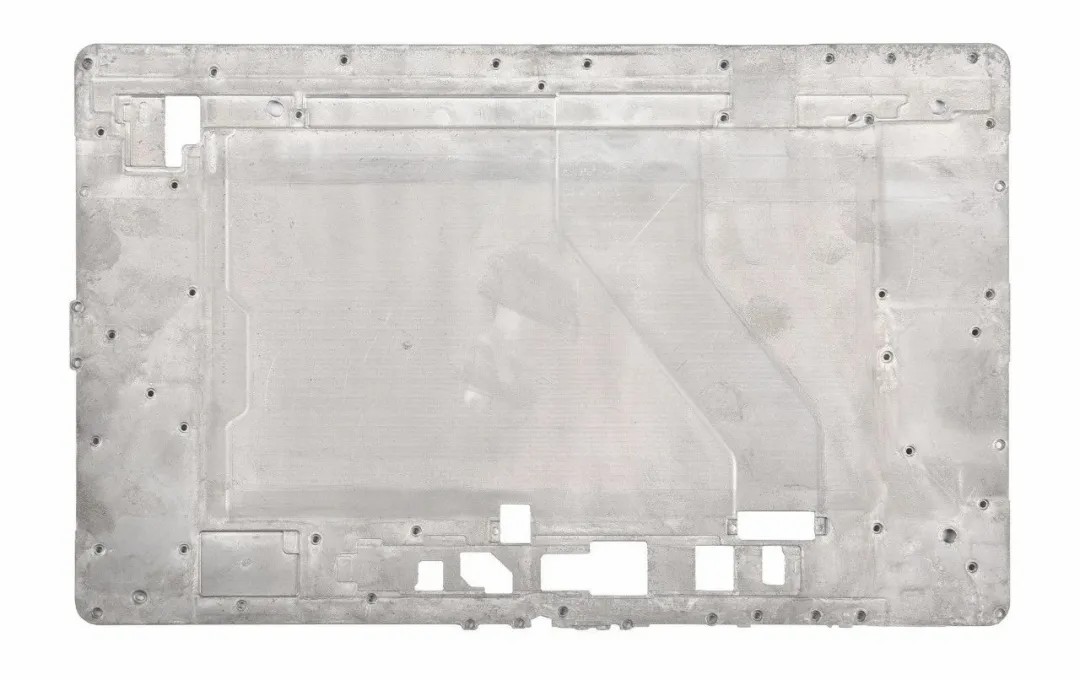

In the die casting workshop of Jin Yahao Precision Metal Technology CO.,LTD. (Jin Shihao) , more than 50 YIZUMI die casting machines remain on 24 hours per day, producing mid-frames for phones and tablet PCs. For example, the annual output of phone mid-frame stands at 60-70 million pieces, which are mainly supplied to the well-known phone brand, such as Huawei, OPPO, Xiaomi.

Jin Yahao Precision Metal Technology CO.,LTD.

Die casting workshop of Jin Yahao

Achieves real-time monitoring of workshop production

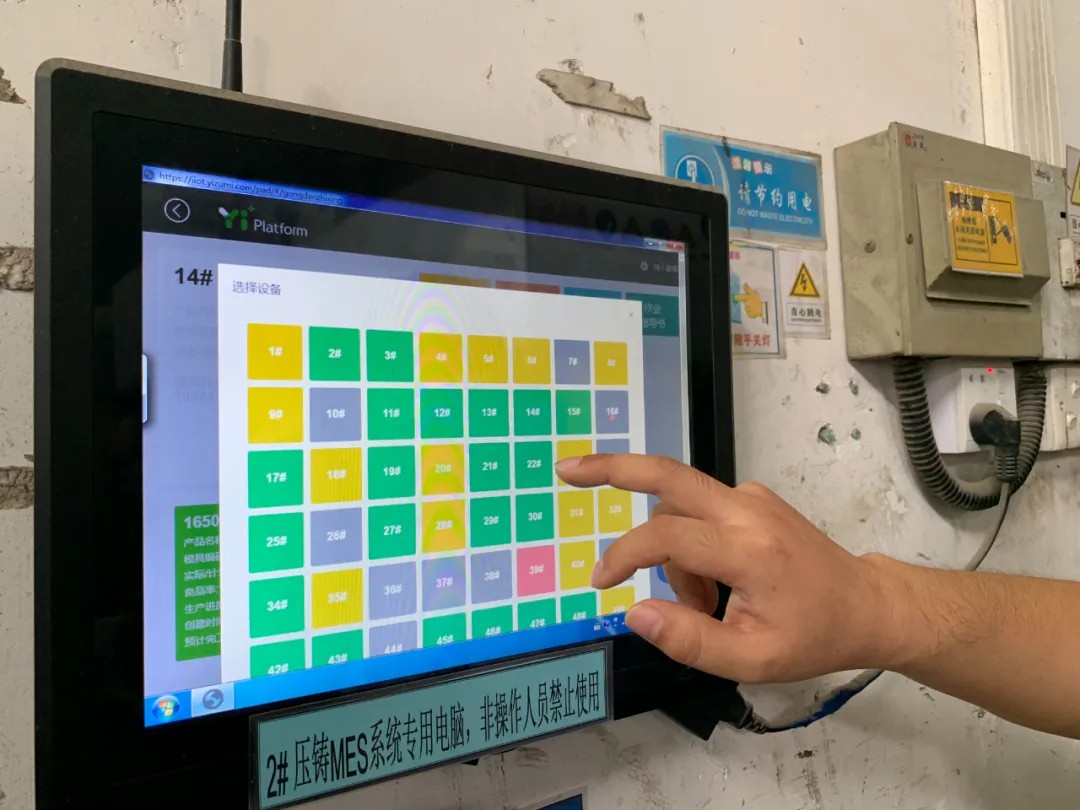

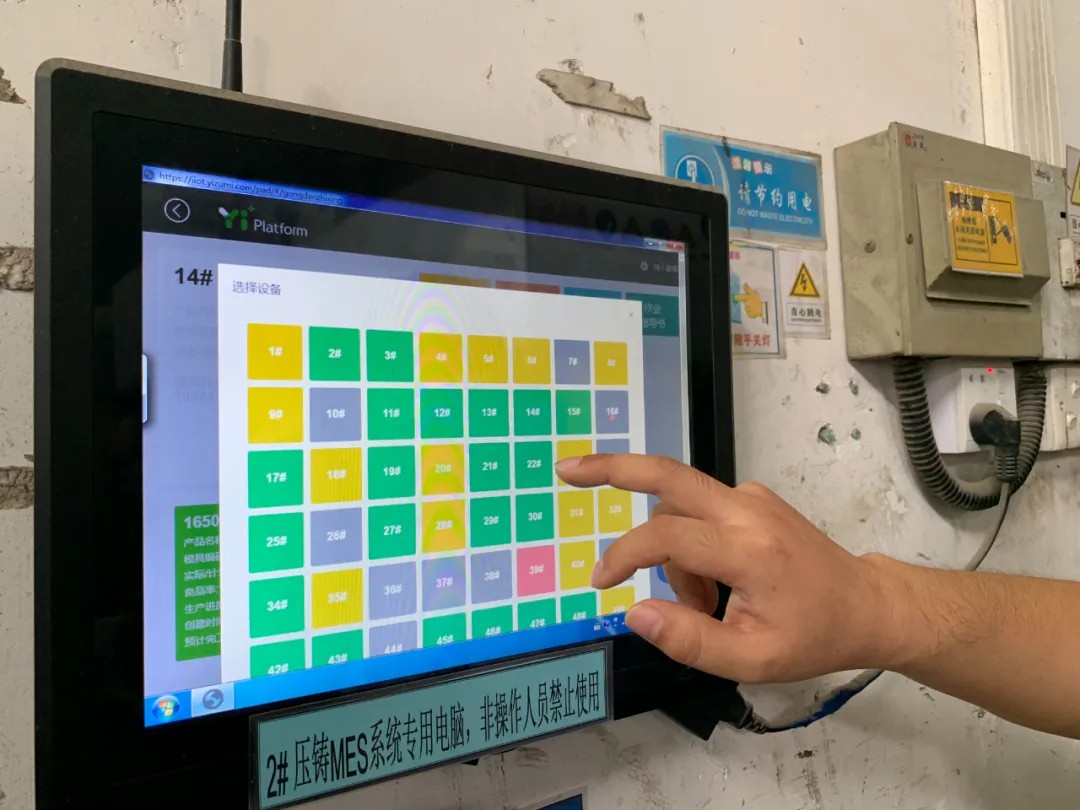

How to master the production status of each machine in real time when requiring long production time and large output? Engineers can easily check through the YIZUMI Yi+ Manufacturing platform, a small screen placing in the corner of the die casting workshop, on which machine condition, real time operation data, cycle time, yield, and other data are shown.

In the past, company managers didn't get those complicated data for production forecasting and adjustment until the data were manually typed in and organized by operators. Now, managers can monitor the production status at any time and place through phone or computer, management efficiency has been significantly improved. Jin Yahao chief Financial Officer Zhang Di described: “YIZUMI is one of the first batch of enterprises who try to explore the industrial Internet application in the industry. More results such as efficiency improvement might be shown in the on-going practice and exploration, we are very confident in Yi+ intelligent manufacturing platform.”

Intelligent factory management

As 5G technology begins to expand, 5G smartphone market have been booming. Higher demands are put forward for the die casting process, product precision and production efficiency of structural parts such as smartphone mid-frames and tablet mid-frames. Jin Yahao realized that if continues to adapt the traditional manufacturing method, it will leave the company in a profit margin squeeze. Along with the arrival of the 5G era, the cost management ability has become the key for industry competition, which depends on whether the information sources on cost controlling is supportive enough. Digitization and informatization is necessary so that factory management can be intelligent, Zhang Di said. With agile insights, Jin Yahao has planned to take the road to digital transformation as early as the beginning of 2020.

Why did Jin Yahao choose to cooperate with YIZUMI in the first step of transformation? In fact, as early as 2013, Jin Yahao began to purchase YIZUMI die casting machine and gradually automate the manufacturing process. “We have cooperated with YIZUMI for 8 years. It has proved that YIZUMI die casting machine is stable in whole, the product yield is maintained at over 80%, and the after-sales service team responses quickly and provides careful maintenance. We decided to introduce the Yi+ intelligent manufacturing platform because we trusted in YIZUMI’s brand, product and service.” In order to provide precise solutions, the technical team from YIZUMI Intelligent Interconnection Dept. arranged an on-site research and helped manage every manufacturing steps and procedures at Jin Yahao’s workshop.

Yi+ intelligent manufacturing platform

YIZUMI launched the Yi+ intelligent manufacturing platform in 2018, which could effectively solve manufacturing pain points and improve production efficiency as well as product quality by adopting the new generation of technologies such as IOT, Cloud Computing, Big Data.

This solution has been applied in the actual production. At the beginning of 2021, Jin Yahao officially put the Yi+ intelligent manufacturing platform into service, which means the beginning of digitalized factory management.

The data in the original ERP system of enterprises is supposed to be shifted to the Yi MES system. After the data is connected, the system could offer functions such as remote monitoring, failure warming, maintenance management, parameter monitoring, data statistics, and order tracking, Improving equipment utilization and product yield.

Jin Yahao hopes to continue to strengthen cooperation with YIZUMI and promote the application of Yi+ intelligent manufacturing platform. Zhang Di said: The data collected by Yi MES system will provide an important basis for the production management in the future, and to help set the process parameters more scientifically. Only when the data is really supportive, the dependence on the technicians can be reduced, the stability and quality of the product can be guaranteed.

With the increasing development of Yi MES system, the next step will be to further apply the processing management which offer professional guidance on process parameter settings to improve processing stability; Through setting up Quality management rules and measurements in the system, the quality of products can be examined on regular basis so that product quality can be improved. And the introduction of intelligent manufacturing and intelligent service can really improve quality, reduce cost and increase efficiency for customers.